Subterranean drone tackling food security wins The High-Temperature Carbon-Fiber 3D Printing Challenge

Based on the 'Crover Effect' for locomotion in granular media, the CROVER robot is able to move through bulk solids and powders. The team wins $25,000 of manufacturing support from Mitsubishi Chemical Advanced Materials to take their design to the next level.

Image credit: Crover

This article was discussed in our Next Byte podcast.

The full article will continue below.

The High-Temperature Carbon-Fiber 3D Printing Challenge invited engineers to submit a design that made use of a newly developed, cutting-edge carbon-fiber material.

Dozens of high-quality submissions were submitted to the challenge, making the jury's task very difficult. Ultimately 11 finalists were selected, these designs were then further assessed on their technical and commercial feasibility, scalability, and sustainability.

The winner of the High-Temperature Carbon-Fiber 3D Printing Challenge is CROVER with their subterranean drone. The team wins $25,000 of manufacturing support from Mitsubishi Chemical Advanced Materials to take their design to the next level.

Based on the 'Crover Effect' for locomotion in granular media, the CROVER robot is able to move through bulk solids and powders - i.e., environments like sand dunes, grain bulks, and chemical powders. While potential applications of the CROVER range from soil sampling on Mars to the recovery of buried objects. Crover's first application is a grain Storage Management system. This helps grain storage operators like farmers, grain merchants and port operators identify critical conditions early and maintain the quality of their stock.

"The winning design is a unique combination of an innovative technology with a significant positive environmental impact that addresses a key global challenge for society: food waste," described Tim Vorage, founder and manager of GrowthGarage, Mitsubishi Chemical Advanced Materials.

Saving grains; securing stable food resources

CROVER is able to propel itself, multi-directionally and semi-non-destructively, on and below the surface of granular bulks – environments like sand dunes, bulk chemical powders, and cereal grains. Cereal grains are the basis of most human diets, yet post-harvest losses during long-term storage are exceptionally high, with storage losses estimated at >630 million tonnes per year.

The main culprit is spoilage due to insects and molds, which can develop because of uncontrolled moisture and temperature conditions. Grain storage operators at cereal storage sites such as farms, grain merchants, millers, and breweries, fight a constant battle with these infestations, which have high-cost implications in terms of lost revenue and cost to rectify. Containing these issues is extremely labor-intensive and poses many health and safety risks.

“At Crover, we want to make sure that every grain that enters a silo or shed exits it with the same quality, and in doing so significantly reduces the incidence of agricultural confined space injuries, in grain storage facilities, by removing, as much as possible, the main causes of such accidents: the presence of workers in the vicinity, or on the surface of the grains,” explains Crover team lead Lorenzo Conti.

“The CROVER system aims to substitute all human intervention in or on the surface of granular bulks. The current first version of our device can automate all those tedious monitoring operations by constantly controlling the parameters of the whole bulk surface, making it easier to comply with assurance schemes and bring peace of mind to grain storage operators such as agri-cooperatives, grain merchants, and farmers,” says Conti.

A global grain storage solution

The CROVER robot can fluently “swim” through bulk solids like cereals and oilseeds, constantly monitoring their conditions while they are still in storage. Reaching areas of the bulk that couldn’t be reached otherwise and mixing the grains as it swims through them, helping maintain their quality without taking the grains out of storage.

This allows grain storage operators to:

● Identify problems in the early onset and intervene before infestations can develop (by implementing accurate Integrated Pest Management (IPM) practices);

● Monitor temperature and moisture throughout the whole storage unit;

● Get alerts of sub-optimal conditions and intervene before the issues arise;

● Increase the performance of the storage system and reduce grain losses;

● Avoid the formation of crusting, ratholing, arching and other dangerous bulk structures;

● Mix the grains, which helps in maintaining their quality, in-situ;

● Lower the use of fumigation, thus reducing costs and environmental impact;

● Avoid risky and dangerous worker walks on the bulk surface or inside grain silos.

Based on data from the World Bank, there are an estimated 3,036,960 grain storage units in the addressable market segment (cereal farms over 20 hectares and off-farm storage sites). A £3000/silo yearly service license places the value of the total addressable market at more than £9 billion globally: £84M in the UK; £558M in the top 5 European markets (France, Germany, Italy, Spain, UK); £1.2B in North America.

Crover is based in Scotland and is made up of team members: Dr. Lorenzo Conti, Artem Lukianov, Gianlorenzo De Santis, Corentin Chauvin-Hameau, James McGinley, Veghell Leo Acun, Bogdan Jackson, Thibault Lacourtablaise, Sanaa Farooqi, Jacky Hao, Joel Keishing.

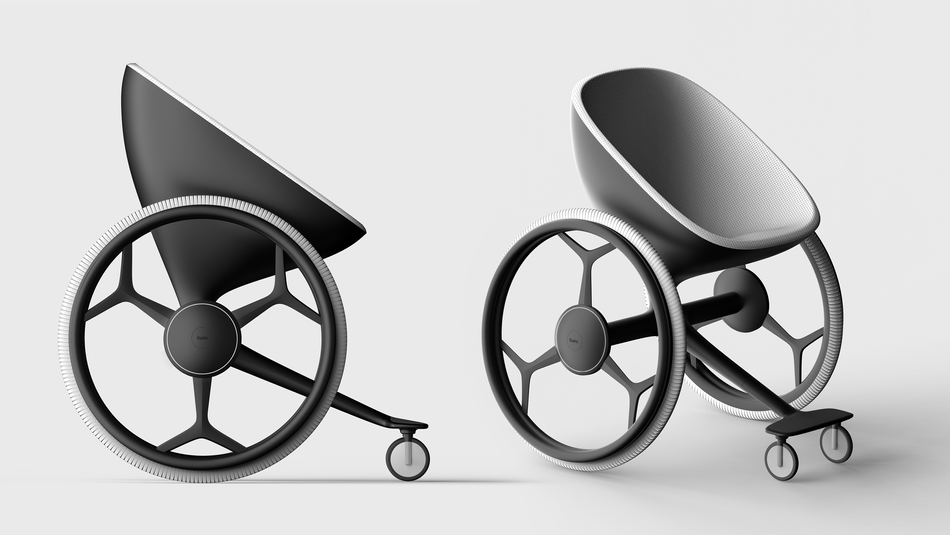

Wevolver Community Vote Prize

We asked the Wevolver community to select their favorite High-Temperature Carbon-Fiber 3D Printing Challenge finalist. The final voting tally was very competitive, with community members casting votes from over 16 countries. The winner of the community vote was Sophia: from Alan Esses and Alberto Esses based in Boston who will receive $10,000 in manufacturing support to develop their idea.

“My brother (an industrial designer) and I (a mechanical engineering student) have always dreamed of putting our combined skills to make a life-changing product. This opportunity arose when we came across the story of Sophia Malthus on YouTube. Sophia became a quadriplegic after a horse-riding accident and is bound to her bed and wheelchair,” explains Alan Esses.

“She described to us how uncomfortable her current wheelchair is and how many issues it arises. This includes her wheelchair being the main focus point when someone sees her; rather than seeing her, they see a boring, mechanical-looking medical device. My brother and I contacted her and asked if she wanted to collaborate with us to design and engineer a customized wheelchair for her free of cost.

Our wheelchair aims to be first, extremely comfortable for Sophia but also designed in a way that she can feel proud every time she is on it rather than ashamed and fix the common discomforts she feels in her current wheelchair. Since then, we have researched, designed, and engineered a customized wheelchair that addresses her main pain points and are now looking for ways to manufacture it. We believe that having the mentorship and resources from Wevolver and Mitsubishi Chemical Advanced Materials that we can make this come to fruition and provide Sophia with a life-altering product. And if we can make this come true for Sophia, we believe we can do it for many others as well," says the designers.

Student prize

After receiving a significant amount of high-quality student entries in the previous Mitsubishi Chemical Advanced Materials challenge, a student prize has been established that provides $5000 in manufacturing support to enable the students to take their idea to the next level.

The student prize winner is the Lunar Exploration Mechanical Arm from Concordia University Capstone Team. The team is made up of seven undergraduate students from Concordia University in Montreal, Quebec.

One of the largest environmental challenges is managing the extreme temperature fluctuations over the course of lunar days and nights while avoiding the use of radioactive thermal units. To address this problem, an all-mechanical motion transmission design has been developed that allows for sensitive electronic components to remain within the insulated enclosure of the rover body.

"To achieve our desired 5 degrees of freedom, a set of drive trains has been designed for each joint and fit inside the body. The arm weight must remain as light as possible to keep the energy required for transportation low, while the push force and lift capacity remain high enough for the arm to be functional for sample collection. Lunar dust is also a concern as it is highly abrasive. The arm will be sealed as much as possible to mitigate this environmental factor," describes the winners.

The scope of this project will not cover power storage or communications. This first prototype will be implemented using a set of 5 motors housed in the rover enclosure individually controlling each joint; however, a subsequent iteration would make use of a gearbox and a single motor to further reduce weight. The application of this type of arm would not be limited to rovers, it could easily be extended to other lunar infrastructure that provided an insulated enclosure for the electronics.

The Concordia team includes Aidan Mitchell, Eric Cappelli-Martell, Sean Le Noble, Erl Bernard, Joseph Corbisiero, Fady Mitry & Mustapha El Makdah .

Challenge finalists

We congratulate all of the finalists. Read more about their projects below.

Micro-Engineered smart Protection Suit by Robin Kocher

This micro-engineered smart suit is designed to protect from harsh climate environments to empower humans to be able to act in difficult conditions. The suits have multiple layers to create modular smart ecosystems that can be customized based on use.

Chassis Structure for an Autonomous Ground-Based Robot by Arnav Bisoi, Michal Kostyal, Baran Sahan, Sajiban Parmeswaran & Mian Ali.

The CF reinforced filament has been used to manufacture load-bearing chassis components a ground-based robot. FEA and Topology Optimisation have been implemented to predict the strength of the 3D printed components and to minimize their weight. The 3D-printed 'skirts' sit on the circumference of the robot giving it a cylindrical aesthetic; this design takes inspiration from a tortoiseshell where the shell provides protection from exterior elements and also supports any top-down loads.

Long Range (200km) BVLOS Inspection Drone by Phillip Keane.

Beagle Systems is one of the only companies in EU with a 200km BVLOS flight permit from EASA, enabling their current generation of drones to perform fully automated infrastructure inspections up to 200km. This project is their next-generation drone, which will be printed in composite plastic, allowing lighter weight and even further flight distances. The team used generative design, topology optimization, and AI-assisted toolpath generation to achieve the drone’s design.

Object-shape adaptive robotic hand by Choi Yongwoon, Valentin Cardenas Keith & Ikeda Yuki.

Cost and weight are critical factors when designing a robotic hand. This design can be adapted to the shape of the object target with the use of only one actuator. While there are other adaptive robotic hand designs out there, most of them require numerous actuators, making them heavy and expensive. This single-actuator robot hand was developed during the team’s 3rd year of university as a project to be included as part of a larger robot design.

High-Performance FPV Quadrocopter Frame by Adam Theo Müller.

This project is a frame for an FPV-quadrocopter designed so each necessary component can be mounted easily. The design is optimized for specific load cases such that it is as lightweight as possible. It is specifically laid out for additive manufacturing techniques to be utilized.

Helicopter hinge by 9T labs.

This design looks to improve the helicopter door hinge that is currently produced in aerospace-grade steel. By using composite materials and cutting edge-manufacturing techniques the new hinge can greatly outperform current designs in weight and strength properties.

Suspension device to enable scale-up and cultivation of t cells and stem cells for therapies by Carl Bachellier.

The device is a mixing impeller that solves the scale-up problem associated with the cultivation of stem cells and t cells for therapeutic use. For example, diabetes and cancer. Mixing small amounts of cells and growing them in the lab is reasonably successful at 1 to 3 liters. To manufacture a therapy at scale, the bioreactors will have higher volumes, approaching 1000 liters in some cases. This mixer allows the mixing of high volumes of cells without shear damage, suspension issues, or oxygen transfer.

DS-1 Minotaur: Open-engineering Aerial Robotics enabled by Advanced Manufacturing by Evandro Valente.

Agility designs and manufactures aerial robots having onboard algorithms that provide GPS-independent mission and navigation-specific decision-making. To keep pace with the fast-evolving sensing and computing industries, the DS-1 Minotaur is entirely 3D printed with a product-ready finish and quality. The team’s vision is to save and improve lives by using drones to perform dangerous missions usually done by people.

About the sponsor: Mitsubishi Chemical Advanced Materials & Growth Garage

Mitsubishi Chemical Advanced Materials is a leading global manufacturer of high-performance materials in the form of semi-finished products and finished parts. The company has locations in 20 countries and more than 2,800 employees. Its specialty engineering thermoplastics and composites are superior in performance to metals and other materials and are used in a wide range of applications, primarily in the capital goods industry. The company is continuously developing new areas of applications in close cooperation with industry leaders in a wide variety of customer markets. The Mitsubishi Chemical Advanced Materials Group is well prepared to further expand its market leadership position.

Growth Garage is a business accelerator program from Mitsubishi Chemical Advanced Materials. Our mission is to support and grow new ideas using our technologies and advanced engineering materials to help tackle some of today's biggest engineering challenges. We are offering the opportunity for engineers and innovators to pitch us their ideas and receive manufacturing support and services.