Sustainable Printed Electronics: Green Materials for Wearable Applications

Additive electronics is intrinsically more sustainable than subtractive processes. Yet the current materials are often based on metallic inks and plastic substrates. This is a particular issue in medical wearables with disposable devices. Hence the need to develop sustainable material options

This article was first published on

www.techblick.comAs part of our series, TechBlick has invited Sandra Lepak-Kuc from Warsaw University to discuss the trends towards sustainable materials in additive electronics and to share their insights on the development of printable graphene pastes for printing on paper to produce disposable electronics. This article originally appeared here

Print Intelligence: Print innovative, print smart, print sustainable, print green

Why? In recent years, sustainable printed electronics have gained tremendous interest in both science and industry. Novel electronics focus on enhancing environmental friendliness while maintaining functionality. Researchers are exploring materials and manufacturing techniques that enable the production of biodegradable or recyclable electronic components, reducing electronic waste and its impact on the environment.

We will be exhibiting together with 77 other exhibitors in Berlin (17-18 OCT 2023). Lets RESHAPE Electronics Together, making it Additive, Sustainable, and Wearable. Explore the programme and plan your visit now. Learn more https://www.techblick.com/electronicsreshaped

We will be exhibiting together with 77 other exhibitors in Berlin (17-18 OCT 2023). Lets RESHAPE Electronics Together, making it Additive, Sustainable, and Wearable. Explore the programme and plan your visit now. Learn more https://www.techblick.com/electronicsreshapedWhere particularly? Some of the most dominant subjects involved in this trend are those related to materials and methods in biomedical applications. Rapid advances in medical technology have historically contributed to significant improvements in patient healthcare. The challenge is to develop modern or improved methods of preventive care. It will also allow to reduce the cost of instrumentation, as well as its deterioration and maintenance expenses.

Very often, disposable products are desired in biomedical applications. Their main advantages are that they do not require disinfection and reduce the risk of spreading pathogens[1]. The COVID pandemic has further escalated the emphasis on single-use products, both due to the increased awareness of pathogen risk and simultaneously by spreading and improving telemedicine, which has become a permanent part of private and public healthcare[2,3].

Why there? In addition to several advantages of disposable appliance components, their disadvantages are increasingly being highlighted. The environmental aspect is recognized as one of the biggest. In the case of ECG electrodes, for example, the solutions currently proposed on the medical market, both traditional and modern disposable ones, are based on substrates made of materials such as PET or PE and sensors or conductive pathways made of Ag/AgCl. These materials are not environmentally friendly. They are not biodegradable, and their combustion produces harmful gases[4].

In the stream of pro-environmental actions mentioned above, an attempt to replace precisely these materials with environmentally friendly, biodegradable, and biocompatible ones would seem the right course[5,6].

What do we need? Challenges are not only directed toward obtaining an electrically conductive layer from recyclable materials. Many more factors are required. It is essential to ensure printability, preferably by methods allowing large-scale printing. Ensuring recyclability of both the print and the substrate. Ensuring proper adhesion of the print to the substrate. Ensuring functionality under complex conditions - as in the above-given example of ECG, the need to work in contact with the human body, sometimes under various external conditions - temperature, exposure to UV light, or humidity (sweat). Moreover, in the case of electronics dedicated to medical applications, it is also necessary to meet the relevant specific standards.

HOW? Alternative materials are being explored that, in between being suitable for printing techniques and having their functionalities, are being made sustainable and less harmful to the environment. This includes using biodegradable substrates, such as cellulose-based materials, instead of traditional non-biodegradable substrates, such as plastic. However, it is a key issue to produce sustainable printing pastes alongside substrates. These are being challenged with increasing demands, the fulfillment of which is often a complex matter, requiring unconventional approaches and innovative ideas.

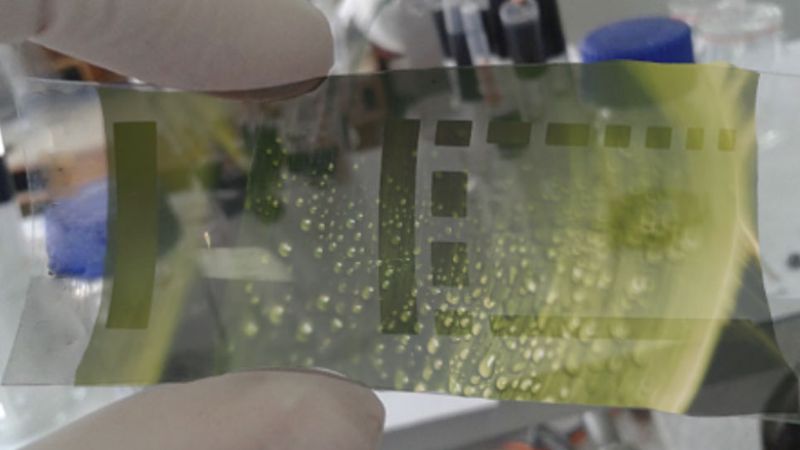

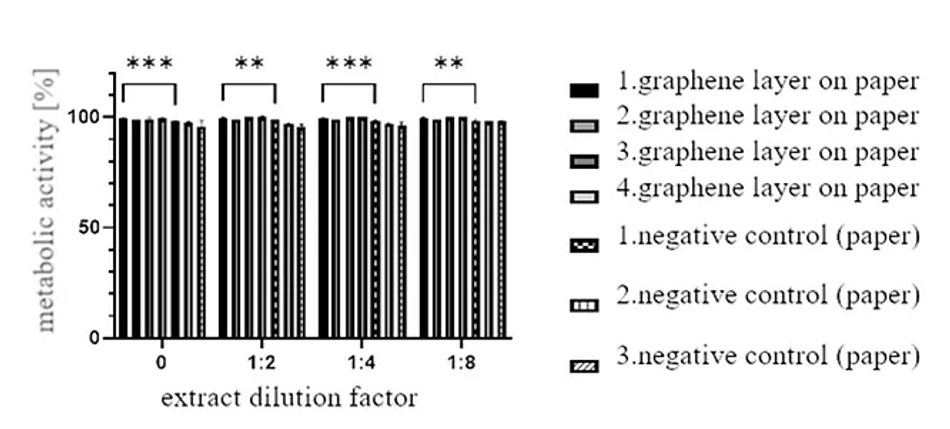

In our research, we go beyond the usual patterns and use materials not previously associated with electronics. These are often unsuccessful attempts, often time-consuming, necessitating unusual methodological solutions. Nevertheless, we have successfully printed graphene pastes based on sodium alginate and glycerine on paper. Subjecting them to cytotoxicity tests showed a total lack of toxic effect of the obtained structures on living cells.

Pastes based on glycerine and various reagents such as gelatine, modified starch or xanthan gum. A huge difficulty we encountered was that such materials often did not allow us to achieve the right rheology for screen printing and thus the relevant printability in this method.

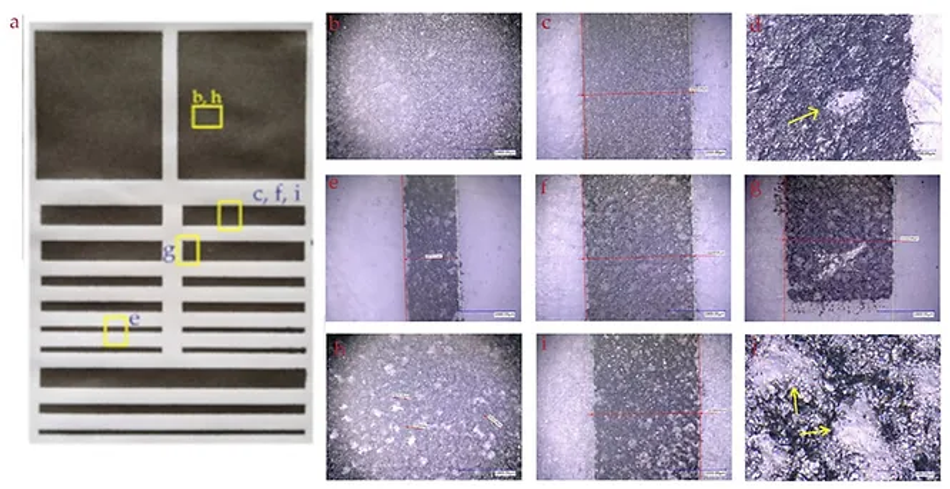

Fig. 1. Digital microscope photographs of prints on paper (b-f) photos of conductive paths in selected positions as marked in (a);

Fig. 2. Metabolic activity of L929 cells treated with sodium alginate, glycerol and graphene layer extract on a paper substrate compared to a negative control (paper). XY plot (GraphPad Prism 9.5.0)

The goal? Our research aims to develop a range of available solutions that will make the greatest possible contribution to protecting the environment and saving the climate.

We will be exhibiting together with 77 other exhibitors in Berlin (17-18 OCT 2023). Lets RESHAPE Electronics Together, making it Additive, Sustainable, and Wearable. Explore the programme and plan your visit now. Learn more https://www.techblick.com/electronicsreshaped

We will be exhibiting together with 77 other exhibitors in Berlin (17-18 OCT 2023). Lets RESHAPE Electronics Together, making it Additive, Sustainable, and Wearable. Explore the programme and plan your visit now. Learn more https://www.techblick.com/electronicsreshapedUltimately, we aim to obtain electrodes (e.g., for ECG) and other electronic structures that are environmentally friendly, recyclable, or even compostable. Ones that could be rinsed under the tap or thrown into the fireplace and burned. The road may be long and complicated, but it is an effort worth taking.

[1] C. Bloe, Br J Nurs 30 (2021) 628–633.

[2] G.B. Colbert, A.V. Venegas-Vera, E.V. Lerma, Rev Cardiovasc Med 21 (2020) 583–587.

[3] J. Portnoy, M. Waller, T. Elliott, J Allergy Clin Immunol Pract 8 (2020) 1489–1491.

[4] K. Sovová, M. Ferus, I. Matulková, P. Španěl, K. Dryahina, O. Dvořák, S. Civiš, Molecular Physics 106 (2008) 1205–1214.

[5] Z. Fang, H. Zhang, S. Qiu, Y. Kuang, J. Zhou, Y. Lan, C. Sun, G. Li, S. Gong, Z. Ma, Advanced Materials Technologies 6 (2021) 2000928.

[6] C. Zhang, R. Cha, P. Zhang, H. Luo, X. Jiang, Chemical Engineering Journal 430 (2022) 132562.