What are End Effectors? Types of End Effectors in Robotics and Applications

End effectors are critical components of robotic systems, enabling robots to interact with and manipulate their environment in various ways.

End effectors are devices attached to the end of a robot’s arm to help it interact with the surrounding environment. End effectors are essential to robotic systems as they handle, manipulate, and sense objects. These devices are the primary means by which robots interact with their environment and perform useful work. End effectors can be customized to suit specific applications and can be designed to perform a wide range of tasks, including gripping, cutting, welding, painting, and more.

In this article, we delve into the world of industrial robotics to understand end-effectors. We provide an in-depth overview of the types of end effectors, their functions, their applications, and their potential impact on the future of robotic automation. We will also look at the more advanced robotic force compliance end effectors and how they manage to offer improved compliance.

What are the types of end effectors used in robots?

End effectors can be broadly classified into three categories based on their design, construction, and application.

Grippers

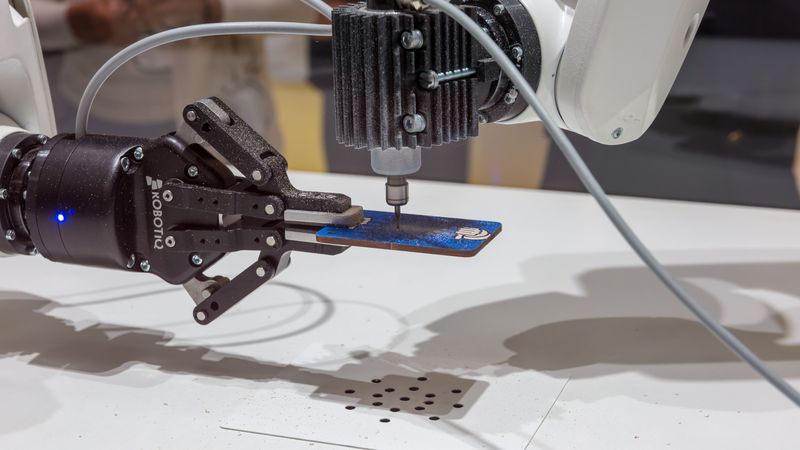

Grippers are used to grasp and hold objects securely. They are one of the most commonly used types of end effectors in robotics and are an essential component of many automated systems. The primary function of grippers is to provide robots with the ability to pick up, move, and manipulate objects in a controlled and repeatable manner. Grippers come in different sizes, shapes, and configurations. Their choice depends on the type and size of the object being handled, the robot's environment, and the specific application.

Here is a list of some different grippers used as a robot’s end effectors:

Mechanical Grippers: Mechanical grippers are the most basic type of grippers and work by using jaws or fingers to grab an object. They are simple, robust, and reliable and are often used in applications that require a firm and stable grasp, such as pick-and-place operations or assembly tasks. Mechanical grippers can be further classified based on the type of jaws or fingers used, such as parallel grippers, angular grippers, or three-finger grippers.

Vacuum Grippers: Vacuum grippers use suction cups to grab and hold things. They are primarily used in applications that require handling flat, smooth, or porous objects, such as glass panels or printed circuit boards. Vacuum cups are easy to use, have a fast cycle time, and are highly reliable. However, they may not be suitable for handling irregularly shaped or heavy payloads.

Magnetic Grippers: Magnetic grippers use magnetic fields to hold ferromagnetic items such as steel plates. They are used in applications that require handling heavy or irregularly shaped objects that cannot be easily managed with mechanical or vacuum grippers. Magnetic grippers are highly reliable, require minimal maintenance, and have a fast cycle time. However, they may not be suitable for handling non-ferromagnetic materials.

Servo Grippers: Servo grippers use motors and gearboxes to control the gripping force and positioning of the robot precisely. They are used in applications that require high precision and flexibility, such as quality control or inspection tasks. Servo grippers can be programmed to adjust their gripping force and position based on the size and shape of the object being handled, making them highly versatile.

A pneumatically controlled magnet gripper for pick and place applications

Every gripper has its own set of advantages and disadvantages. Hence, the choice of gripper depends on the specific application it is going to be used for.

Mechanical grippers are simple, reliable, and cost-effective but may not be suitable for handling irregularly shaped objects.

Vacuum grippers are easy to use, highly reliable, and have a fast cycle time but may not be suitable for handling heavy or non-porous objects.

Magnetic grippers are highly reliable and require minimal maintenance but may not be suitable for handling non-ferromagnetic materials.

Servo grippers are highly precise and flexible but may be more expensive and require more complex control systems.

Sensors

Sensors are essential components of robotic systems, providing robots with the ability to gain a perception of their environment. Sensors gather data about the robot's surroundings, including the position and orientation of objects around it and the robot itself. The robot's control system then uses this information to decide how to interact with its environment. Here are some of the most commonly used sensors in end effectors:

Proximity sensors: Proximity sensors are used to detect the presence or absence of objects in the proximity of the end effector. These sensors can detect various targets, including metal, plastic, and even liquids.

Force/torque sensors: Force/torque sensors measure the amount of force or torque being applied to the robot or to the objects it interacts with. These sensors are often used in robotic grippers to measure the force required to grip an object or in robotic arms to measure the force required to move an object.

Cameras: Vision sensors use cameras and other imaging technologies to provide visual feedback on the position, orientation, and movement of the end effector and the objects it interacts with. These sensors are often used in applications requiring precise positioning and manipulation. Cameras are also used for object recognition, tracking, navigation, and obstacle avoidance. Cameras for end effectors can even have 3D and thermal imaging capabilities if the application demands.

Light sensors: Light sensors can detect the presence or absence of light and are used to provide feedback on the position of objects in low-light environments.

Magnetic sensors: Magnetic sensors or hall effect sensors are used to detect the presence of magnetic fields. They can detect the position and orientation of objects that contain magnets.

Range Sensors: Range sensors are used to measure the distance between the robot’s end effector and objects near it.

The advantages of sensors include increased accuracy, efficiency, and flexibility. They provide robots with the ability to perceive their environment and make decisions based on that information, making them ideal for applications that require precision or that operate in dynamic or complex environments. However, sensors and cameras can also be expensive, and their accuracy can be affected by lighting and environmental conditions.

Process Tools

Process tools in robot end effectors are attachments or devices used to perform specific tasks. They work in coordination with the robotic arm, providing additional functionalities to the robotic system. They can be as simple as a screwdriver or as complex as a whole robot. Here are some examples of process tools used in end effectors:

Welding guns: Welding guns deliver a massive amount of electric current to the workpiece/workpieces on which welding is to be performed. After it cools down, a strong and permanent bond is formed.

Painting Spray Guns: Painting spray guns are used as end effectors in robotic painting systems. They are designed to apply a precise and consistent amount of paint to a workpiece. The spray gun can be programmed to adjust the angle and distance of the spray to achieve the desired coverage and finish.

Cutting Tools: Cutting tools are used to cut and shape workpieces. They can be designed for a variety of materials and thicknesses, including metal, plastic, and wood. Cutting tools can be mounted on the robotic arm as an end effector and programmed to cut the workpiece to a specific size and shape.

Grinding and Sanding Tools: Grinding and sanding tools are used to smooth and finish surfaces on a workpiece. These tools can be mounted on the robotic arm as an end effector, and the arm can be programmed to move the tool over the surface of the workpiece to achieve the desired finish.

Deburring Tools: Deburring tools remove burrs or rough edges from a workpiece after it has been cut or machined. Deburring tools can be mounted onto a robotic arm as an end effector and programmed to deburr the edges of the workpiece to a specific size and shape.

Dispensers: Dispenser end effectors are a process tool used in robotics designed to dispense various materials, such as adhesives, sealants, and lubricants, onto a workpiece or component. These are used in 3D printing systems too.

Robotic Force Compliance End Effectors

Robotic Force Compliance End Effectors (RFCEEs) allow robots to exert force on an object while also sensing the resistance or reaction of the object to the applied force and adjusting the operation accordingly.

RFCEEs are typically used in tasks where robots need to interact with objects that are not rigidly fixed in place or where there is a degree of uncertainty about the location or orientation of the object. For example, in assembly tasks, RFCEEs can help the robot grip and position a part with greater precision and accuracy, even if the part is slightly misaligned or the robot is not perfectly calibrated.

Compliance in RFCEEs can be achieved through various mechanisms, such as using springs, hydraulic or pneumatic systems.

One of the advantages of using RFCEEs is that they can help to reduce the risk of damage to the object being manipulated or to the robot itself. By providing a more natural and intuitive interaction with the environment, RFCEEs can also improve the overall performance of the robot in complex and dynamic environments.

Active Compliant Technology

Active Compliant Technology (ACT) is a type of technology used in end effectors that uses sensors and control systems to actively adjust to changes in the environment or in the task being performed, providing greater flexibility, adaptability, and versatility.

ACT end effectors are also designed to provide a certain level of stiffness or compliance, depending on the task at hand. The level of stiffness can be adjusted to suit the specific requirements of the task, such as the size and weight of the object being manipulated or the desired level of precision and accuracy to offer a dynamic and responsive interaction with the environment.

One of the key benefits of ACT end effectors is their ability to handle delicate or fragile objects with greater care and precision. ACT end effectors can also be used in tasks where the location or orientation of the object being manipulated is not precisely known.

ACT end effectors can be particularly useful in tasks that require the robot to perform a combination of rigid and compliant movements. For example, in assembly tasks, the robot may need to position a part with a high degree of accuracy and then gently press it into place, requiring both precise and compliant movements.

Passive Technology

Passive end effectors are designed with materials or structures that provide a certain level of flexibility or compliance, allowing them to adapt to changes in the environment or in the task being performed without any sort of sensing or control.

Passive end effectors may use various materials or structures to achieve compliance, such as springs, rubber, or flexible materials. These materials or structures are designed to absorb forces and distribute them evenly, reducing the risk of damage to the object being manipulated or to the robot itself.

One of the advantages of using passive end effectors is that they are generally simpler and more cost-effective than ACT end effectors. They also tend to be more reliable and require less maintenance since they do not have any electronic components or sensors that can fail or get damaged.

Passive end effectors can be particularly useful in tasks where the level of compliance needed is consistent and predictable. For example, in packaging or palletizing applications, where the robot needs to grip and position boxes or other objects with a predetermined level of force, passive end effectors can provide the necessary compliance without needing sensors or control systems.

How to choose the right End Effector?

Choosing the right end effector for a particular robotic application can be a complex and vital decision, as it can significantly impact the robot's effectiveness and efficiency. Here are some key factors to consider when choosing the right end effector for a robotic application:

Task requirements: The first step in choosing an end effector is to understand the task requirements, such as the shape, size, and weight of the objects that the robot will be manipulating, the required precision and speed of the task, and any environmental factors that may affect the end effector's performance.

End effector capabilities: Once the task requirements are understood, the next step is to evaluate the capabilities of various end effectors to determine which one is best suited for the task. For example, a mechanical gripper may be used for picking up and holding objects with a smooth surface, but those who understand the capabilities of other end effectors know a vacuum gripper would be an ideal choice for this particular case.

Compatibility with the robotic system: It is necessary to ensure that the chosen end effector is compatible with the robotic system’s specifications. Some robotic tools may require specific types of end effectors, so it is important to check compatibility before deciding.

Maintenance and repair: End effectors may require maintenance and repair over time, so it is important to consider the ease of maintenance and availability of replacement parts when choosing an end effector.

Cost: One thing that goes without saying when choosing an end effector is the need to consider its cost in relation to its capabilities and expected lifespan, as well as the cost of any additional components required to integrate it into the robotic system.

Overall, choosing the right end effector for a robotic application requires careful consideration of the task requirements, end effector capabilities, compatibility with the robotic system, maintenance and repair needs, and cost. By carefully evaluating these factors, you can select an end effector that will enable your robotic system to perform its intended tasks effectively and efficiently.

Applications of End Effectors

End effectors, with their wide range of applications, play a vital role in all industries employing robots. Here are some industries requiring customized applications at the end of a robotic arm:

Manufacturing: End effectors are widely used in manufacturing applications to increase productivity and efficiency. They can be used for tasks such as pick-and-place, assembly, welding, and material handling. End effectors can be designed to handle a wide range of materials, including metals, plastics, ceramics, and can also be equipped with sensors to ensure precise positioning and movement of materials.

Food and Beverage Industry: End effectors are also used in the food and beverage industry to automate tasks such as packaging, sorting, and palletizing. End effectors can handle fragile and perishable items with care and can be designed to meet strict hygiene standards. They can also be equipped with sensors to detect contaminants and ensure food safety.

A cooking robot that makes omelets. Customizing end effectors unlocks the possibility of using robots for new and unexpected applications.

Healthcare: In the healthcare industry, end effectors are used for tasks such as medication dispensing, patient transfer, and surgery. They can handle delicate medical instruments and supplies with precision and accuracy, reducing the risk of human error. End effectors can also be designed to assist in rehabilitation and therapy for patients with mobility impairments.

Agriculture: End effectors can be used in the agriculture industry for tasks such as harvesting, planting, and crop maintenance. They can handle delicate produce without damaging it and can be designed to work in challenging outdoor environments. End effectors can also be equipped with sensors to detect the ripeness of crops and to monitor soil conditions.

Construction: In the construction industry, end effectors can be used for tasks such as concrete pouring, drilling, and excavation. They can handle heavy materials and perform repetitive tasks with precision, reducing the risk of human injury and improving productivity. End effectors can also be designed to work in challenging environments, such as high altitudes or underwater.

Logistics: End effectors are widely used in logistics applications for palletizing, sorting, and shipping tasks. They can handle a wide range of package sizes and weights and can be designed to work in high-speed, high-volume environments.

Automotive: End effectors are used in the automotive industry to handle various components such as engines, transmissions, and wheels, as well as to perform tasks such as welding, painting, and assembly.

Entertainment: End effectors are also used in the entertainment industry for tasks such as set building, prop handling, and camera positioning. They can handle delicate and intricate objects with precision and can be designed to work in a variety of settings, such as theaters, movie sets, and amusement parks. They can be equipped with sensors to ensure precise camera positioning and movement.

Future

As robotics technology continues to advance, there are many exciting possibilities for future developments and advancements in end effectors. Some potential areas of progress include:

Improved Sensing and Adaptive Control: One of the key areas of development in end effectors is improved sensing and control. Advancements in sensing technology will enable end effectors to better detect and respond to changes in their environment, allowing for more precise and efficient operations. In addition, advancements in control systems will make end effectors more adaptable to changing tasks and situations.

Greater Dexterity: Future end effectors may also be designed with greater dexterity, allowing them to handle more complex tasks and objects with greater precision. Advancements in materials and manufacturing techniques will enable the creation of more lightweight and versatile end effectors with the ability to handle a broader range of materials and shapes.

Increased Mobility: End effectors are often attached to robotic arms that are limited in their range of motion. Future advancements in mobility technology may allow end effectors to move more freely and with greater precision. This could enable them to access hard-to-reach areas, perform more complex tasks, and operate in a wider range of environments.

Improved Human-Robot Collaboration: As robotics technology continues to advance, there will be a growing need for human-robot collaboration in many industries. Future end effectors may be designed to work more closely with human operators, with improved safety features and more intuitive controls. This could lead to greater efficiency and productivity, as well as new possibilities for human-robot interaction.

Soft robotics enables development of end effectors that interact more naturally with their environments

Integration with Artificial Intelligence: The integration of end effectors with artificial intelligence (AI) is another exciting possibility for future advancements. End effectors equipped with AI will be able to learn and adapt to their environment, improving their efficiency and precision over time. They may also be able to work autonomously, freeing up human operators to focus on more complex tasks.

More Applications: As end effectors continue to advance and become more versatile, we can expect to see more applications in a wide range of industries. For example, end effectors may be used in constructing large infrastructure projects, such as bridges and tunnels, or in exploring remote or hazardous environments, such as space or deep sea exploration.

Recommended reading: 7 Types of Industrial Robots: Advantages, Disadvantages, Applications, and More

Key Takeaways

In conclusion, end effectors are an essential component of robotic systems, enabling them to interact with the world around them in a variety of ways. End effectors are designed to perform specific tasks, such as gripping, sensing, and manipulating objects, and are often customizable to suit the needs of different industries and applications.

The key takeaways from this article are:

There are several end effectors, including grippers, sensors, and process tools, each with their own set of advantages and limitations.

Selecting the right end effector for a given task requires careful consideration of factors such as the size and shape of the objects being handled, the required precision and speed, and the environment in which the robot will be operating.

Future advancements in end effector technology will enable greater efficiency, precision, and productivity across many different industries.

As robotics technology continues to advance, end effectors will play an increasingly important role in a wide range of industries, from manufacturing and logistics to healthcare and entertainment. By staying up to date on the latest advancements and best practices, businesses can maximize the value of their robotic systems and gain a competitive edge in their respective industries.

References

[1] Lad NA, Ballal YP, Kulkarni PD. Study of End Effectors–A Review. Int J Trend Res Dev. 2015;2(5). http://www.ijtrd.com/papers/IJTRD201.pdf

[2] Z. Samadikhoshkho, K. Zareinia and F. Janabi-Sharifi, "A Brief Review on Robotic Grippers Classifications," 2019 IEEE Canadian Conference of Electrical and Computer Engineering (CCECE), Edmonton, AB, Canada, 2019, pp. 1-4, doi: 10.1109/CCECE.2019.8861780.