An engineers guide to Multiphysics: Modeling real-world behaviour and predicting performance.

Article #5 of our simulation series. Advances in software and increased access to inexpensive compute power means more and more engineers can use Multiphysics analysis to improve their design processes.

Tags

This is the final article in a series about simulation tools sponsored by Altair. Altair is hosting the free virtual global event, Don't Be Late To Simulate on November 30, 2021: 2:00 p.m. (Paris) and at 8:00 a.m. (New York).

Ahead of the event, Wevolver sat down with Warren Dias, Director of Global Business Development of Altair to discuss what multiphysics analysis is and what impact it's making on design and product development.

Can you explain what Multiphysics analysis is and briefly how it works?

Multiphysics analysis is a really exciting approach to applying engineering simulation technologies in product development programs. Traditionally, simulation technologies were used to either predict or validate the behaviour of a structure or system, before any physical prototypes exist. This might involve investigating what will happen if the product is dropped or crashed, the heat generated by the internal components, the aerodynamics of the surface, etc.

Once you can accurately predict the behaviour, you can start to optimize it, using the intelligent design technology to improve the performance of the product. Multiphysics analysis allows you to capture the behaviour as a result of interaction between the different physics involved, so how the structural behaviour will affect the fluid flow around the structure, which in turn will affect the structural behaviour. For example, this can be done as sequential simulations or co-simulation, involving multiple disciplines running simultaneously and exchanging information at every timestep.

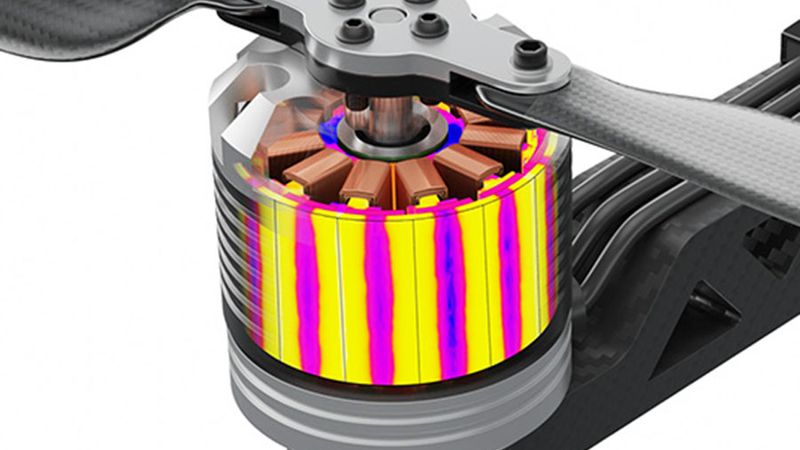

The Multiphysics Optimization Platform for e-Motor Innovation

What are the potential benefits of a Multiphysics design approach?

While studying the individual disciplines is fundamental to ensure basic performance criteria are met, many systems operate in environments where their behaviour is determined and influenced by the interactions between different physics disciplines. Using a multiphysics design approach allows us to model real-world behaviour and predict performance under those conditions more accurately. The better we understand the real-world behaviour in the design stage, before physical products are produced, the more we can optimize product performance and design out any potential issues, ultimately saving later re-work and cost.

Do you see a drive from industry to adopt a Multiphysics analysis approach to design?

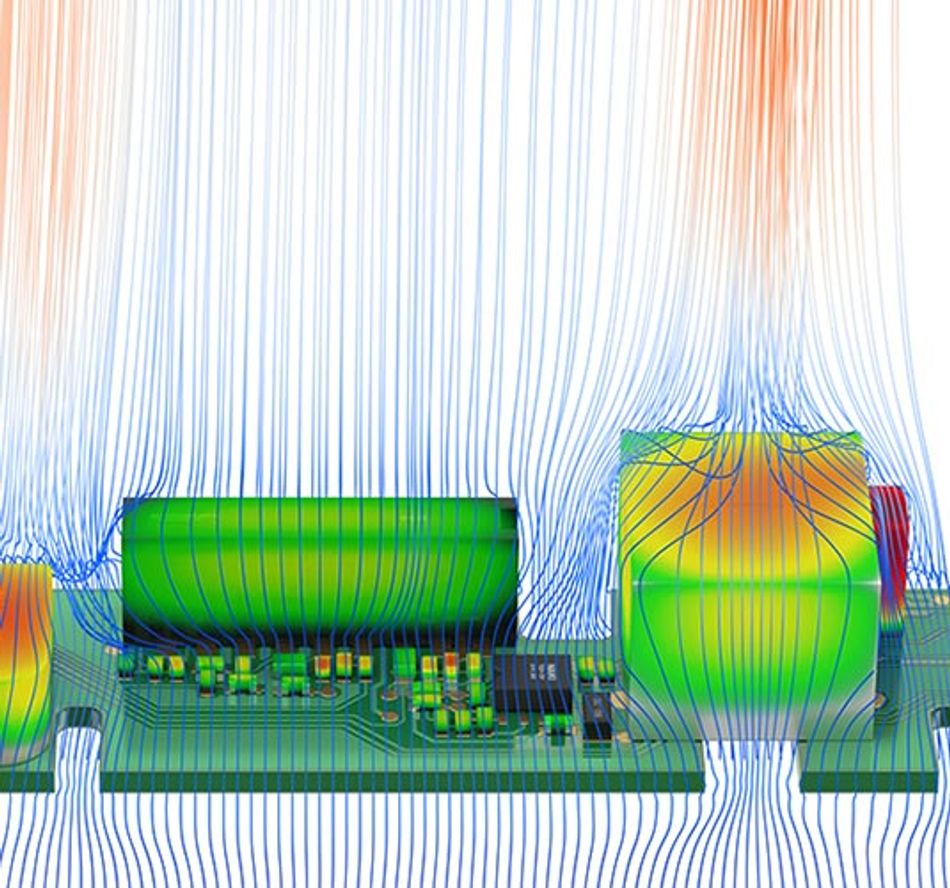

With slimmer margins on designs and more complex and integrated systems, there has been a steady increase over the years in the need to capture multiphysics phenomenon. For instance, with the increasing dependence on electronics, it becomes important to study how efficiently the board is being cooled for example, while ensuring that the solder joints don’t fail. In this example, you have a coupled thermal-structural problem to be solved.

Similarly, with all the electrification efforts, being able to study voltage and the heat generated due to current flow involves an electrical-thermal coupled simulation. Add to that the need to predict stresses or deflections, and you now have a multiphysics problem involving electrical, thermal, and structural simulations.

What has facilitated the rise in interest in Multiphysics analysis?

Multiphysics analysis has been seen as an ideal scenario for quite some time, but the technologies were not always there to deliver it. Speed is key for any design process and a Multiphysics approach has to be able to deliver to the timescales of a demanding development process. The development of simple, easy-to-use Multiphysics solutions such as Altair SimLab and the streamlined workflows built around it have been a key driver for the rise in interest, along with the increased availability of inexpensive compute power.

We’re also seeing wider trends such as the electric transportation revolutions drive further interest. When developing an electric motor, one aspect is to design the motor itself and its performance characteristics such as torque, etc., But a key-dependent characteristic is its noise and vibration profile. So now, multiphysics analysis needs to be added to the bill-of-analyses to address such needs.

Have you got any examples where you’ve seen Multiphysics analysis have a big impact on a design?

We’ve worked with customers across the globe on implementing Multiphysics analysis into their design processes, from automotive to aerospace and energy. A recent example is GN Audio, best known for its Jabra range of speakers and headsets. Their team is using a multiphysics approach to assess structural performance, ensure a robust product through virtual drop-testing while designing for enhanced comfort for long web meetings!

They’re presenting some of this work in an upcoming online event we’re hosting on 30th November. Register for the event, “Improving Comfort and Robustness of Jabra Headsets with Simulation Driven Design,” at the event page.

What do you think is the future for Multiphysics in product development?

Previously, a Multiphysics approach was just for advanced use cases and specialist users, but now it is becoming more commonplace, easier to set up, and quicker to get results. We’re seeing steady growth in applications and more and more companies, often those with smaller design teams, exploring the approach and developing fantastic products as a result.

I expect more complex and integrated systems to drive the push for multiphysics analysis. Unified environments with simple and easy-to-use workflows as with Altair SimLab. Further, more availability and access to HPC systems will help democratize multiphysics simulations. Beyond just the analysis, we expect the need for optimization around multiphysics to also grow. More companies will look to not just predict behaviour, but to improve performance and innovate in what is a highly competitive global marketplace.

You can see practical applications of Multiphysics analysis and advice on how you can get started with the approach during Altair’s ‘Don’t Be Late To Simulate’ online event taking place on 30th November 2021. Register here.

This is the final of five articles in a series about simulation tools. The series covers case studies on using simulation in product design and explores the applications of multiphysics simulation.

The first article introduced simulation-driven design.

The second article examined the challenges cad-based FEA poses.

The third article outlined how German Startup, ATNA used Altair to accelerate the design of their briquetting machine.

The fourth article discussed an upcoming workshop demonstrating the many ways simulation can be used to optimize and improve the design process, leading to more efficient products and reducing time to market.

About the sponsor: Altair

Altair is a global technology company, which provides software and cloud solutions in the areas of simulation, high-performance computing (HPC), and artificial intelligence (AI). Altair enables organizations in nearly every industry to compete more effectively in a connected world while creating a more sustainable future.

Search for articles and topics on Wevolver

Tags