Breaking Down the Data Barriers in AI Adoption for Industrial Vision

Learn how agnostic systems like Awentia's No-Data Vision Foundation Model addresses key barriers to AI adoption such as data dependency, cost, and complexity across industries like agriculture, robotics and manufacturing.

The promise of AI-powered vision systems is at the heart of Industry 4.0, providing unprecedented automation, precision and operational efficiency. However, the path to implementing these technologies is loaded with challenges. Industries ranging from manufacturing to agriculture frequently find themselves unable to bridge the gap between potential and reality due to a number of long-standing problems. Among challenges are the reliance on enormous datasets, expensive prices and the technical knowledge necessary to create and maintain AI systems.

Awentia, a deep-tech inventor, provides a novel solution with its No-Data AI Platform. Unlike previous solutions, Awentia's platform does not require considerable data preparation, allowing businesses to begin reaping benefits on the first day of deployment. This article explores the core challenges in adopting AI for industrial vision and highlights how Awentia’s solutions can transform these hurdles into opportunities.

Understanding the Challenges Facing AI Integration in Industrial Contexts

The Data Problem in Vision Applications

Traditional computer vision systems require large, high-quality datasets for training and validation. However, obtaining such datasets is far from easy. Limited or unavailable data is a common problem for industries operating in niche markets. For example, manually labelling hundreds of thousands of photos could be necessary to create a robust dataset for fault identification in a specialised manufacturing process. This is a time-consuming and expensive operation.

Furthermore, even when datasets are available, keeping them relevant in dynamic industrial settings is difficult. Changes in lighting, item positioning, or even modest operational changes might make old data obsolete, necessitating periodic updates and retraining of AI models.

Awentia tackles this difficulty with its Vision Foundation Model, which does not rely on pre-existing datasets. Instead, it uses proprietary algorithms to adapt to real-time circumstances, decreasing the entrance hurdle for sectors.

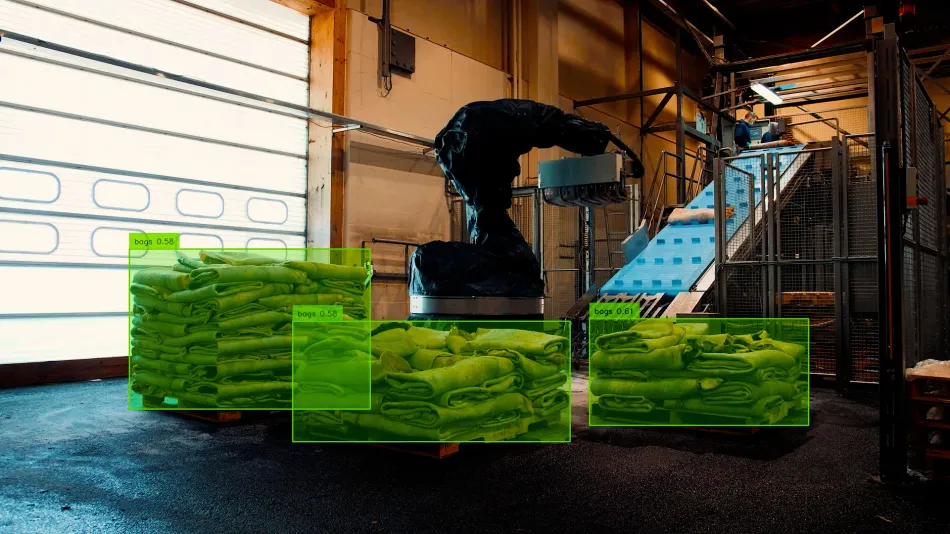

Image: AI-Powered Object Detection using the Vision Foundation Model.

Image: AI-Powered Object Detection using the Vision Foundation Model.

Cost and Scalability Limitations

Cost is another important impediment. Traditional vision systems necessitate significant capital investment in specialised hardware, cloud storage and processing infrastructure. For smaller businesses, these expenses might be prohibitively expensive.

Scaling these systems increases the difficulty. Consider a manufacturing company trying to implement an AI-powered vision system across different facilities with varying operational requirements. The work required to tailor the system to each location, together with the costs, can easily spiral out of control.

Awentia's AVT SDK provides a scalable solution that is cost-effective and resource-efficient. By eliminating the need for large initial expenditures and complex infrastructure, Awentia enables enterprises of all sizes to deploy AI vision systems without sacrificing scalability.

Integration and Technical Complexity

Industrial environments are rarely uniform. Integrating AI technologies into existing workflows frequently necessitates significant customisation and technical skill. For instance, integrating an AI vision system into a decades-old production line may need rebuilding elements of the process, restructuring existing machines and recruiting specialised workers to manage the implementation.

Adoption of AI technologies is further complicated by their steep learning curve. Engineers and technicians must become acquainted with complicated tools and algorithms, which diverts focus from their primary responsibilities.

Awentia simplifies this process by providing a plug-and-play solution that smoothly interacts with existing systems. Its user-friendly SDK requires no technical knowledge, making it accessible to teams with no prior AI experience.

Long-Term Maintenance Burden

Once deployed, traditional AI systems are not self-sustaining. They require constant upgrades to remain effective, whether to adapt changes in industrial processes or to provide new features. This needs continual investment in data collecting, algorithm optimisation and hardware upkeep, which raises the overall cost of ownership.

Awentia’s approach eliminates this recurring burden. Its agnostic engine is intended to run efficiently over time with minimal intervention, resulting in continuous performance without the need for frequent upgrades.

Adapting to Anything: The Rise of Agnostic AI Systems

The Power of the AVT SDK

The AVT SDK is a testament to Awentia’s innovation. This software development kit serves as a universal enabler for industrial vision applications. It offers a versatile, modular architecture that may be tailored to a wide range of applications, from precise manufacturing to real-time monitoring of hazardous areas.

The hybrid architecture combines edge computing and cloud capabilities to provide real-time processing on-site while accessing cloud resources for enhanced analytics. This guarantees that users get the best of both worlds: speed and scalability.

The Vision Foundation Model

At the core of Awentia’s offering is the Vision Foundation Model, a proprietary algorithm that removes the need for extensive datasets. Instead of relying on pre-trained models that often require customization, Awentia’s solution is ready to use out of the box. Engineers and R&D professionals can deploy the model with minimal configuration, significantly reducing development time.

This model is particularly beneficial in scenarios where rapid deployment is critical, such as emergency response or infrastructure monitoring.

The Importance of Agnostic Systems in Vision Technology

Agnostic systems like Awentia’s are designed for versatility. They can adapt to various industrial environments without requiring extensive reconfiguration. This flexibility is especially valuable in industries where workflows and conditions can vary widely, such as agriculture or logistics. For instance, an agnostic system deployed in a vineyard to monitor grape health can be quickly reconfigured to analyze soil conditions, providing a comprehensive solution for farmers.

Collaboration as a Path to Innovation

Awentia’s co-development model fosters innovation through collaboration. By working closely with industry partners, Awentia tailors its solutions to address specific challenges. These partnerships also provide valuable feedback, enabling continuous improvement of the platform. This approach not only accelerates product development but also ensures that Awentia’s solutions remain relevant and effective across a wide range of applications.

Real-World Applications: Success Stories Across Industries

Drones for Rescue Missions

Awentia’s technology is making waves in search and rescue operations. At Electronica in Munich, Awentia partnered with System Electronics to demonstrate drones equipped with AI vision for detecting survivors in disaster-stricken areas. These drones navigate complex environments autonomously, showcasing the potential of AI in saving lives.

Agritech Innovations

In Argentina and Italy, Awentia’s AI-powered vision systems have been deployed in farms to monitor crop health and productivity. By analyzing real-time data, farmers receive actionable insights that help optimize irrigation, reduce waste and maximize yield.

Smart Warehouse Automation

Scheduled for rollout in 2025, Awentia is collaborating with a leading robotics company to enhance warehouse automation. Their AI-driven solutions will optimize robotic arms for precision tasks, improving efficiency and reducing operational costs.

Transform Your Industrial Vision with Awentia

Awentia’s No-Data AI Platform is transforming the way industries approach vision systems. By addressing the challenges of data dependency, cost and complexity, Awentia is paving the way for a new era of industrial automation.

Whether you’re an R&D professional, an innovation manager, or a system integrator, Awentia invites you to explore its solutions. Schedule a demo today and take the first step toward revolutionizing your industrial vision.