Carbon Fiber Reinforced PPS as an alternative to PEEK and metal

High-performance thermoplastic composites can be used to replace metals. While PEEK is the benchmark for engineering performance, reinforced PPS is a genuine low-cost alternative.

The industrial applications of engineering thermoplastics like PC and high-performance thermoplastics like PEEK are growing. In 3D printable filament form, these materials offer a lightweight alternative to metals like steel and aluminum in industries like aerospace and energy.

Reinforcing these high-performance plastics with additives can further improve their performance. Chopped carbon fiber, for example, increases strength and stiffness and can be added to low- and mid-priced engineering plastics as well as high-performance plastics. As long as the 3D printer nozzle can handle abrasive materials, these composites can be printed in much the same way as ordinary thermoplastics.

The main drawback of high-performance composites like reinforced PEEK is the high cost of the required 3D printing hardware. Such materials require extremely high extrusion and chamber temperatures, and the price of suitable hardware — typically reaching six figures — often nullifies the general cost benefits of plastic 3D printing technology.

This article looks at carbon fiber reinforced PPS as a means of achieving performance comparable to metal and PEEK but with lower temperature and cost demands.

What is PPS?

Polyphenylene sulfide (PPS) is a semi-crystalline thermoplastic that can be classified as a high-performance plastic alongside materials like PEEK and PEI.

Widely used in machining, molding, and additive manufacturing, PPS offers good mechanical properties, a high temperature resistance compared to standard and engineering thermoplastics, and flame retardancy. However, its most desirable characteristic is its excellent chemical resistance: PPS is resistant to many acids, alkalis, and solvents, as well as certain strong oxidants in certain conditions. For strong oxidants like chlorine dioxide, a coating or lining may be required.

Due to its desirable characteristics and favorable price compared to PEEK, PPS has a wide range of applications across industries. Its mechanical and chemical properties make it useful in automotive, energy, and chemical processing, while its flame retardancy and self-extinguishing nature have contributed to its status as a go-to material for electrical and electronic parts like SMT devices, motor housings, and transistor sealings.

Not only impressive from a thermoplastics standpoint, PPS is regularly used as a genuine alternative to metals like steel and aluminum. Its thermal stability and supreme chemical resistance make it usable in harsh chemical environments, while it is notably resistant to corrosion and the effects of automotive fluids.

PPS as a composite

For added strength and stiffness, PPS can be reinforced with additives like chopped carbon fiber or fiberglass, forming a composite material. In fact, PPS is more commonly sold as a “filled” material than an unfilled one.

According to researchers, the “addition of carbons can greatly improve the mechanical properties, tribological properties, post-fire structural integrity, and electrical/thermal conductivity of… PPS blends and composites.”

Carbon fiber reinforced PPS can be used for similar applications to unfilled PPS. However, the improved mechanical properties make it a suitable material for components like tooling, jigs, and fixtures. PPS composites are particularly suited to industrial FFF additive manufacturing, as these 3D printers cannot print materials like pure carbon fiber.

3D printing PPS

PPS, in both its unfilled and composite form, offers a fairly accessible route to the 3D printing of high-performance thermoplastic parts. This is thanks to its printing temperature of around 320 °C, which is high but not extremely so.

While a 320 °C extrusion temperature is beyond the capacity of most FFF 3D printers, it is significantly lower than the temperature required for 3D printing PEEK, which is around 400 °C. (PEEK also requires a very high chamber temperature.) Accordingly, PPS parts have a lower temperature resistance than PEEK parts, but they can still be used for demanding applications in which temperatures reach up to around 230 °C.

The type of 3D printer required for printing PPS is somewhere between an industrial-grade FFF printer and a specialist high-temperature FFF printer. Reliable production-level printers can cost around $10,000, while best-in-class high-temperature machines like the Stratasys Fortus 450mc cost around $150,000, which may be considered prohibitively expensive for small and midsize businesses.

When printing carbon fiber reinforced PPS, nozzle durability must be considered as well as temperature, as the chopped fibers are more abrasive than the thermoplastic base material and can therefore damage ordinary brass hardware.

A suitable build surface for PPS is PEI sheet, with the print bed heated to around 80 °C. For intricate 3D printed PPS parts printed on a dual-extrusion machine, the material is compatible with PVA support material.

3D printed PPS reinforced with carbon fiber is suitable for applications such as functional prototypes, tooling for molding and other processes, and manufacturing aids like jigs and fixtures. Industries using reinforced PPS filament include automotive, rail, and aerospace.

High performance, low cost

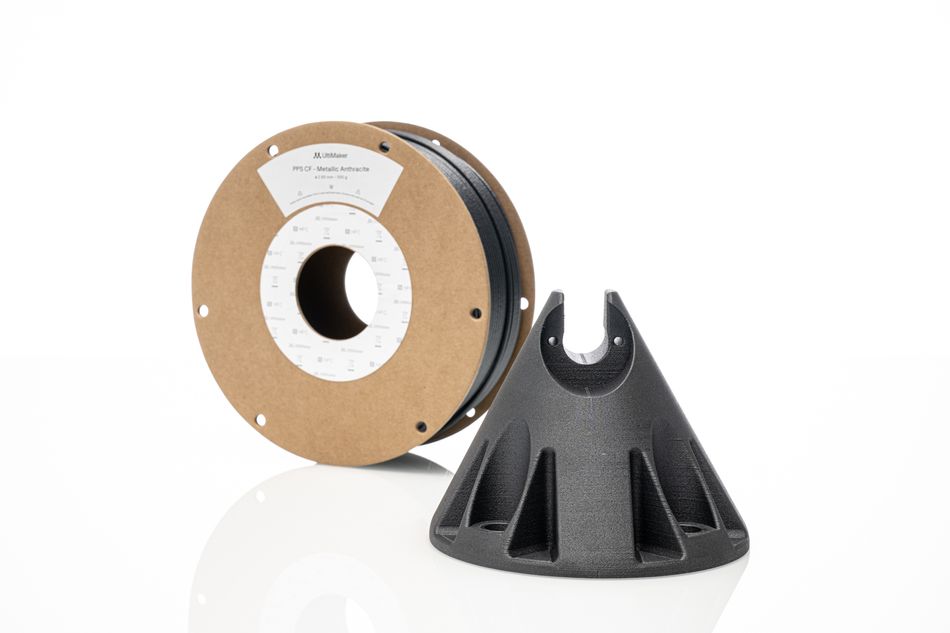

New additive manufacturing systems are making PPS 3D printing accessible to a wider range of users. For example, the UltiMaker Factor 4, which began shipping in May 2024, has a highly wear-resistant print core that enables printing temperatures up to 340 °C — adequate for printing carbon fiber reinforced PPS and many engineering thermoplastics.

What is unique about modern systems like the Factor 4 is their intermediate market positioning. Despite being able to print a genuine high-performance material like carbon fiber reinforced PPS, the Factor 4 is priced closer to an ordinary professional-grade desktop 3D printer than a high-temperature PEEK 3D printer.

To meet the needs of users in industries like electronics and automotive, UltiMaker has also developed its own composite material, UltiMaker PPS CF, tailored for use in the Factor 4. With consistent flow and desirable material properties, the material is formulated to offer high performance while being easy to print. The combination of printer and material also results in excellent dimensional accuracy, exhibiting minimal shrinkage compared to PEEK.

Like other carbon fiber PPS materials, UltiMaker PPS CF is highly recommended for functional prototypes and indirect manufacturing components, though its excellent chemical and heat resistance opens up a broad range of possible applications including end-use parts. The UltiMaker formulated PPS-CF is Flame retardant (V0-94) and guarantees low warpage also on large parts, setting it apart from alternative PPS CF filament providers.

Application examples

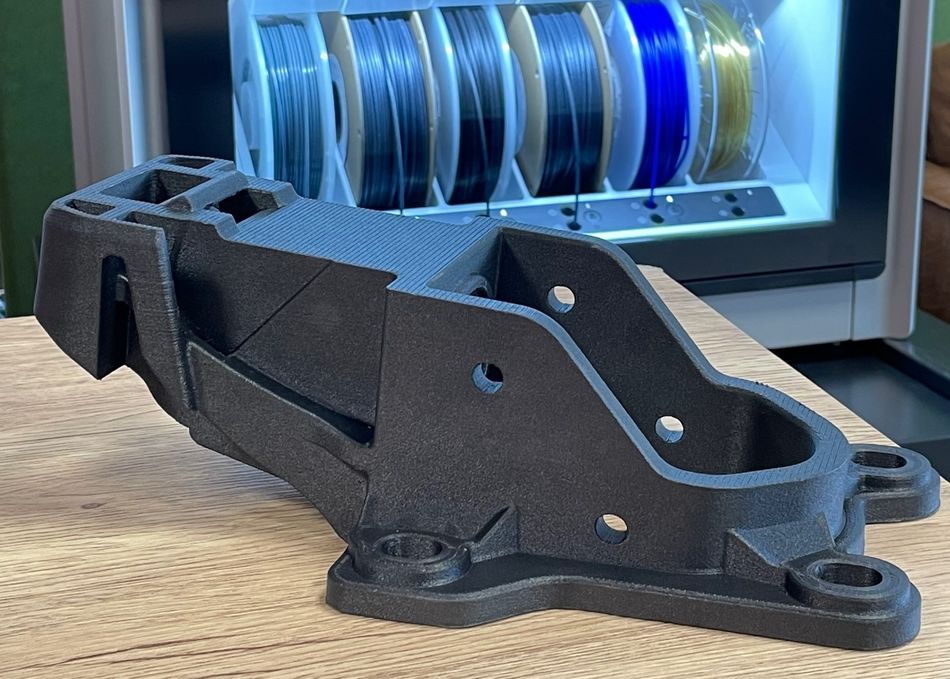

Air freight fastener

This holder is used to securely fasten air freight or to safely stow components in the air freight packaging. Accordingly, it must be temperature-resistant, very strong and stable, and resistant to chemicals – application requirements that are all met with PPS CF. Another advantage of additive manufacturing is that the design can be adapted repeatedly, with all iterations meeting the necessary certifications thanks to the material used.

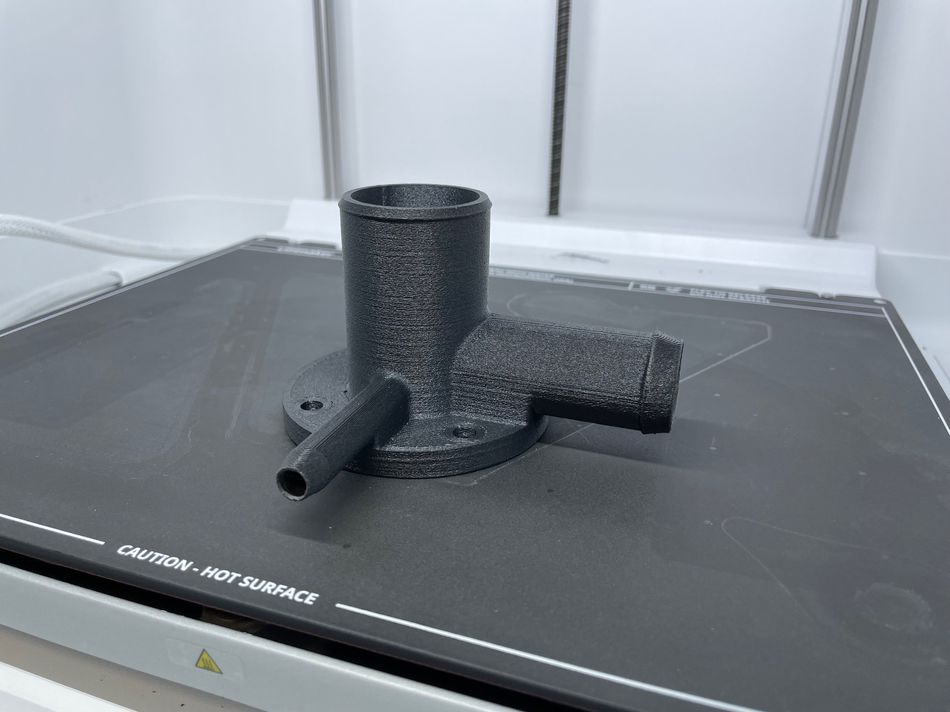

High-pressure pump valve

This pump valve is installed in a train to conduct liquids or chemicals. But because it had become an obsolete component (it was no longer produced), the entire pump assembly would need to be replaced – costing approximately €5,000. Using PPS CF, it can now be 3D printed, so that it still meets the UL94 V0 standard for non-flammability and also for use with hot acids.

Sensor Bracket

This simple bracket is used in the production line and around the site to quickly mount sensors, cameras or other necessary extensions. Priority is given to ensure that the component can withstand extreme loads in outdoor use, including weather conditions, impact resistance or fire protection conditions.

New possibilities

Carbon fiber-reinforced PPS is a high-performance material suited to some of the most demanding industrial applications. Some additive manufacturing end-users might assume that they need the most expensive materials and hardware to achieve engineering-grade quality coupled with high levels of design freedom. However, the UltiMaker Factor 4 and its specially formulated PPS CF material show that this is no longer the case.

If you want to know more about the UltiMaker Factor 4 and the wide variety of engineering materials that can be printed on it, watch this video.