Design for Metrology in Additive Manufacturing

Designing for AM, in general, has its challenges. One challenge is ensuring that your designs will be measurable using X-ray Computed Tomography (XCT). Below, I briefly go over this and invite you to watch my presentation diving deeper into the subject.

This article was first published on

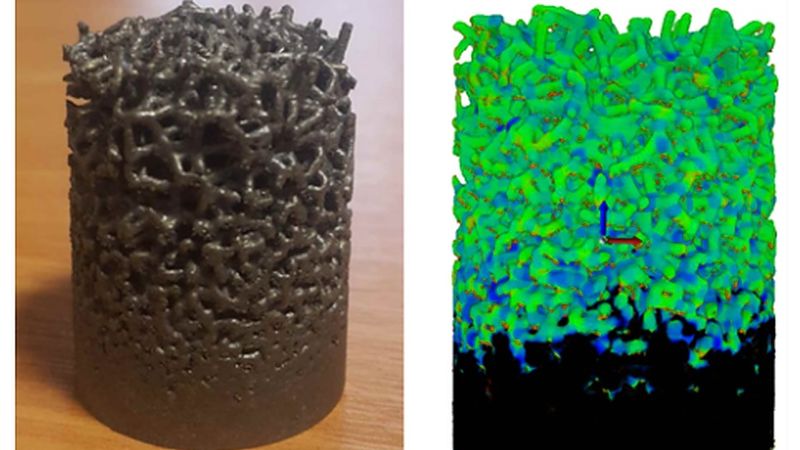

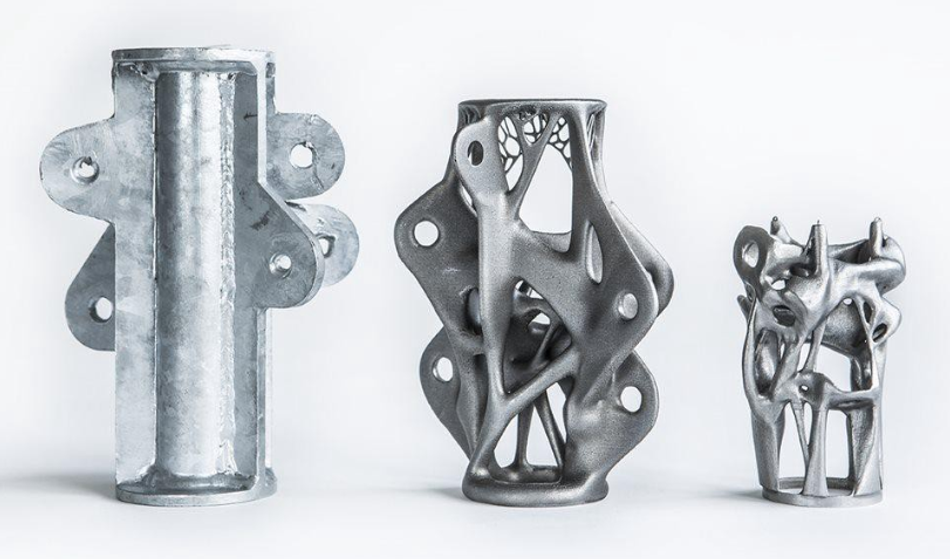

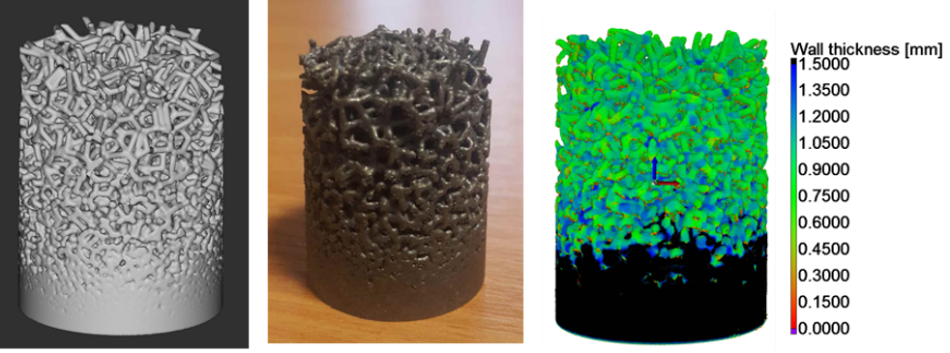

ntopology.comWith the rise of design for additive manufacturing (DfAM) awareness, more efficient and functional designs are being made taking advantage of additive manufacturing (AM) complexity. However, at the same time, since these designs are usually complex enough to not be manufactured using conventional manufacturing methods, they are also complex enough to not be measurable using conventional metrology tools.

To tackle this challenge, a non-conventional metrology tool is usually used, X-ray Computed Tomography (XCT). While XCT still lacks standardisation and needs more research to better generate uncertainty statements, it is becoming more and more popular in the AM field.

References

[1] Mercuri, Valentina. (2018). Form and structural optimization: from beam modeling to 3D printing of reinforced concrete members.

This article was first published on the nTopology blog.