Designing Collaborative Robots: Maximizing Productivity and Safety

Article 4 of our Cobot Series: Collaborative robots are becoming invaluable for industry, as they improve safety and increase productivity, but there are still improvements to be made in design and regulation.

Image: Robotiq

This is the fourth article of an eight-part series that explores how collaborative robots or cobots are transforming industrial workspaces. It will survey the technologies that have converged to make robotic influence possible, unpack the unique engineering challenges robotics pose, and describe the solutions that are leading the way to the influential robots of the future.

The articles were originally published in an e-magazine, and have been substantially edited by Wevolver to update them and make them available on the Wevolver platform. This series is sponsored by Mouser, an online distributor of electronic components. Through their sponsorship, Mouser Electronics supports spreading knowledge about collaborative robots.

Introduction

Industrial robots are essential in factories where they provide an effective addition to the repetitive, high-volume assembly line tasks done by manual workers. The machines can continuously repeat high-precision tasks for many years with only the occasional interruption for routine maintenance. Boosted productivity ensures a return on the initial high capital investment.

But relatively low-cost human workers remain the best option for low-volume, high-mix, intricate assembly work because they are dexterous, flexible, and able to solve problems that would grind a machine to a halt. Collaborative robots—the lightweight, compact, and relatively inexpensive cousins of full-size industrial robots—are now being introduced to combine the advantages of robots with the assets of humans. However, because collaborative robots share the workspace with humans, new engineering techniques are required to maximize productivity while keeping the workers safe.

Sharing the Workspace

Collaborative robots fill a niche in a manufacturing environment where the product mix is consolidating and volumes are increasing but not to the extent that justifies full automation. The robots can do the picking of parts, lifting and fetching, and repetitive, routine actions while the humans work on the intricate fabrication and intellectual challenges of the process.

Collaboration is not a natural extension for traditional industrial robots. The International Organization for Standardization (ISO) defines an industrial robot as “An automatically controlled, reprogrammable, multipurpose manipulator programmable in three or more axes, which can be either fixed in place or mobile for use in industrial automation applications.” The description fits a machine purpose-designed for maximum productivity without human assistance.

It’s not surprising that from the introduction of industrial robots in the 1970s, a division on the factory floor has remained a requirement for the safe automation of their high-volume applications. Today, workers are kept well away and the machines are enclosed behind metal barriers to eliminate the hazards posed by rapidly moving and heavy mechanical parts. Basic external sensor technology provokes an emergency stop of the industrial robots when someone or something crosses a beam or triggers a switch by opening the barrier. And when technicians do intentionally enter the robots’ operating envelopes for maintenance or reprogramming, the machines are powered-down with their arms locked in a safe position.

Maximizing speed, strength, and precision remain important for collaborative robots, but to maximize the advantages of collaborative working, humans, and robots need to work in harmony. And to justify the introduction of a collaborative robot, it must cost no more than the equivalent for human labor. A robot that’s moving parts into position and adding quick-drying adhesive is of little value if a human co-worker still has the previous two to three workpieces to fit together. But more importantly than that, robots must be constantly aware of where the humans are positioned, how they are moving, and the force they’re applying when contact is made (whether intentionally or unintentionally) to ensure safe working.

The key design objectives for collaborative robots can be summarized as achieving:

- Safe interaction with human workers and delicate assembly equipment

- Reduced costs to justify use of robotic labor applications

- Robotic operations at a rate compatible with human capabilities

- Clean and low-noise operations

- Compact and light form factors

- Simple and fast programming by non-expert workers to cope with high-mix production

Collaborative Robot System Design Guidelines

Key factors in collaborative robot design relate to the fact that the machine and human share the same workspace. The designer needs not only to ensure that efficiency is high but also that the robot is constantly aware of the sometimes-unpredictable movements of its co-worker and can react in a safe manner. The designer also needs to ensure that the robot doesn’t apply excessive force if there’s intentional or unintentional contact between itself and the human. This adds complexity because unlike industrial robots in which safety systems are not an intrinsic part of the robot, collaborative robots contain safety systems that are generally integrated into its own structure and controlled by its own systems.

Fortunately, guidance on these design challenges comes in the form of international safety standards for collaborative robots, which have been developed in parallel with the rapid introduction of these robots in the workplace. For example, the International Organization for Standardization (ISO) provides some guidelines for designing collaborative robots in its ISO 10218 document, and a technical specification (TS) created by the organization, the ISO/TS 15066, focuses on the safety of collaborative robots. ISO/TS 15066 highlights the importance of safety-related control system integrity with regards to controlling process parameters such as speed and force. (Note: ISO/TS 15066 represents a voluntary document and is not a standard; however, it is expected to form the basis of a standard in the future.)

ISO/TS 15066 also provides general information for a collaborative robot designer to use, such as information explaining the need for a risk assessment of hazards in the workspace. For example, even the best robot design can’t be considered safe if it allows the robot to wave around a sharp object with its manipulator. In another example, the workspace could be dangerous if it’s closed in by fixed objects that cause a worker to become trapped then crushed by robot movement.

The key sections of ISO/TS 15066 address the design of workspaces, design of a robot’s operations, and the transitions between a robot’s collaborative and non-collaborative operations. Specifically, the document provides extensive details for implementing the following collaborative-operation requirements, which creates safe, efficient solutions that fulfil the design objectives mentioned above:

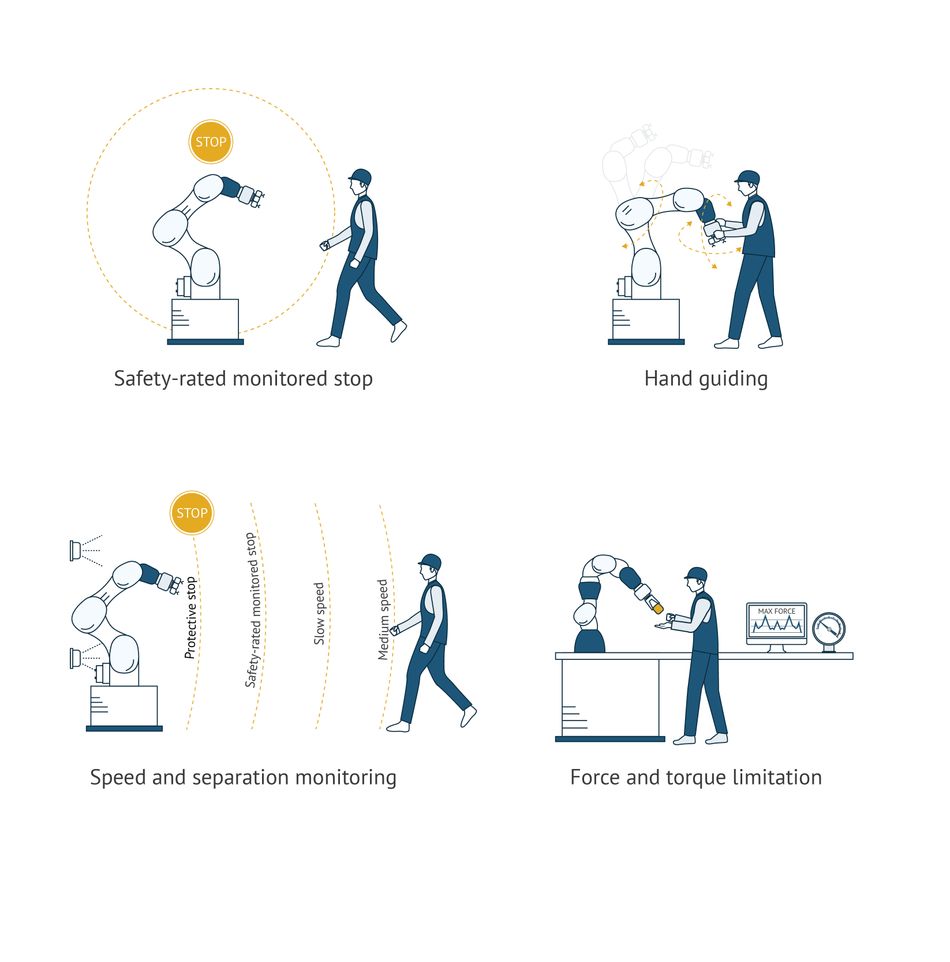

Safety-Rated Monitored Stop

A safety-rated monitored stop is an assured robot stop without removing power and occurs when a human worker enters the collaborative workspace. The system ensures that the robot and human don’t move at the same time and is primarily employed when the robot is rapidly moving heavy parts through the workspace.

Hand-Guided Operation

Before a hand-guided operation can start, a robot must perform a safety-rated monitored stop. During the operation, a worker is in direct contact with the robot arm and can utilize hand controls to move it. This operation is used for lift assists or highly variable “tool” applications.

Speed and Separation Monitoring

This collaborative work method is perhaps the most relevant, as it allows the operator and robot to move simultaneously within the workplace by equipping the robot with sensors to monitor how close in proximity the worker is. At large separations, the robot continues to operate at medium speed, but upon closer approaches, the robot reduces its speed, and at very close approaches, it comes to a complete safety-rated monitored stop.

Power and Force Limiting

Power and force limiting are required in applications where there could be intentional or unintentional contact between a collaborative robot (or any workpiece) and a worker when both are working in the collaborative workspace. Contact can either be quasi-static, such as the clamping part of a worker’s body between a robot’s manipulator and a fixed object, or transient, such as the knocking into a part of a co-worker’s body where the worker is able to recoil.

Design Safety Challenges

With some adaptations to limit cost, size, and complexity, collaborative robot designers can employ existing industrial robot technology for some systems while still implementing the work methods described above. For example, the safety-rated monitored stop is an established technology for industrial robots that uses safety barriers to implement an emergency stop when a human enters the operational envelope.

Speed and separation monitoring demand new engineering techniques considering industrial robots are designed to come to a dead halt when a person breaches the work zone. In contrast, collaborative robots will keep moving, albeit at a reduced speed, when workers are sharing the workspace unless an approach is close enough to trigger a safety-rated monitored stop. Key to implementing such systems is integrating sensors into the robot’s control systems so that the closed-loop feedback enables rapid motor response when speed reduction is necessary.

But the most difficult design challenge is power and force limiting. Designers can learn little from industrial robot design because its emphasis is on load capacity and speed. An annex for ISO/TS 15066 offers help by suggesting limits to quasi-static and transient forces for pain thresholds as well as minor, reversible, and irreversible injury thresholds for humans. Transient force thresholds can be twice as high as quasi-static ones because they occur within a shorter timeframe and the worker is able to recoil.

While research continues on pain and injury thresholds, the present guidelines recommend lowering clamping risks by reducing a robot’s speed to less than 250mm/s and its force to less than 150N during speed and separation monitoring operations, though transient forces can be twice as high but must not be applied for longer than 500ms.

Meeting these thresholds is challenging. For example, a 2kg robot arm carrying a 0.5kg load and moving at 1m/s must decelerate at 60m/s2 to limit its crushing force to below 150N if unintentional contact occurs. In that time, the arm will travel 8mm, which is acceptable for collaborative operation. An identical robot arm carrying a 3kg load would need to decelerate at 19m/s2 to limit its crushing force to less than 150N, during which time it will have traveled 27mm (which is acceptable with padding). This example illustrates that the robot designer must consider the differing dynamic forces generated by collaborative robots with different payloads and speed of movement capabilities.

Other advice in the ISO guidelines includes:

- Eliminating pinch and crush points on the robot

- Reducing robot inertia and mass

- Reducing robot velocity when it approaches a fixed surface, so it can stop quickly

- Increasing the surface area of contact points

- Organizing the workspace layout to limit clamping points and to allow recoil after transient collisions

Case Study: The Collaborative Robot Joint

A major challenge in collaborative robot design is engineering lightweight, compact joints that are also able to quickly react to forces acting on the manipulator—such as impact with a co-worker—to eliminate the risk of injury.

Harmonic gears are finding favor for small robots because they enable designers to reduce joint size and weight in comparison to using conventional mesh gears. However, because harmonic gears use a flexure to transmit motion between input and output, the joint exhibits low rotary stiffness compared to a mesh gear alternative.

A lack of stiffness presents a problem for collaborative robot designers because the preferred method for detecting impact between a human and robot is through the change created in motor current, that is, due to a proportional change in motor torque caused by the force generated by the impact. But a lack of stiffness causes the force to “wind up” the slack in the joint before it has any effect on the motor torque. The result of this is a time lag just before the controller detects an increase in motor current and can responds to the impact by slowing, stopping, or reversing the manipulator. Such a delay could cause the coworker to be subject to a greater than recommended transient impact time of 500ms and to a maximum impact force of 300N.

A mechanical solution is to use a larger harmonic gear to improve stiffness, but that increases the size and weight of the robot joint. An alternative is to use dual high-resolution encoders and a software algorithm. Such a solution will incur a small cost increase, but it won’t increase the dimensions of the joint or raise its weight.

Encoders on the input and output sides of a joint will provide the controller with a real-time measure of any lack of stiffness-induced rotary deviation between the actual and programmed positions of the robot. The controller can rapidly compute a first-order compensation for an error, removing the slack from the system and ensuring that intentional or unintentional impact on the manipulator is immediately detected by increased motor torque.

Conclusion

Collaborative robots are making their mark in workspaces, improving productivity by combining robot muscle with human dexterity and problem-solving skills. Factory management, particularly of small to medium-sized production facilities are beginning to understand the array and diversity of assembly applications—currently performed solely by human labor—that collaborative robots can be used for. The impact of collaborative robots is predicted to increase, with growth expectations roughly set to equal the size of today’s entire quantity of industrial robotics by 2025. But it’s still early for the technology, and engineers are now learning that only some of the design techniques used in engineering industrial robots are truly applicable for their collaborative cousins.

Designing collaborative robots is a nascent discipline, and as such, there is little guidance to draw upon. International safety standards for collaborative robots are being developed in parallel with the introduction of the first wave models into the workplace. Suppliers are doing their part by teaming electronics and sensors up with advanced mechanical assemblies to create new critical components, such as specialized joints specifically engineered for the unique demands placed on collaborative robots during everyday duties, operations, and interactions. A new design methodology is required to ensure that collaborative robots remain safe around coworkers while still bringing speed, precision, and load-handling benefits to the job.

This article was originally written by Steven Keeping for Mouser and substantially edited by the Wevolver team. It's the fourth article of a series exploring collaborative robots.

Article One introduces collaborative robots.

Article Two describes the history of Industrial Robots.

Article Three gives an overview of collaborative robots sensor technologies.

Article Five discusses the development of cobot applications in manufacturing.

Article Six explores the challenges of motion control of robotic arms.

Article Seven looks at the potential of AI in cobots.

Article Eight discusses the social impact of cobots.

About the sponsor: Mouser Electronics

Mouser Electronics is a worldwide leading authorized distributor of semiconductors and electronic components for over 800 industry-leading manufacturers. They specialize in the rapid introduction of new products and technologies for design engineers and buyers. Their extensive product offering includes semiconductors, interconnects, passives, and electromechanical components.