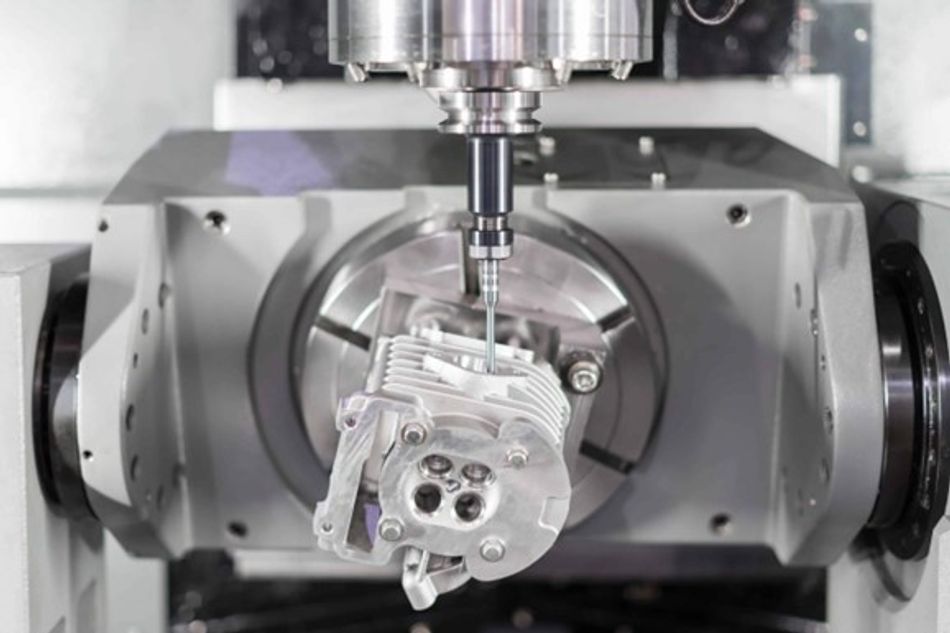

Expert Guide to CNC Machining Surface Finishes: Tips and Practices for Success

The surface finish is an integral part of the CNC machining process because a lot of applications require both aesthetic and functional design. Modern industrial designers have all the right tools and checks to ensure that their designs are functional. So, CNC machining surface finishes is an area where they can cause their product to stand out from the crowd.

The surface finish is an integral part of the CNC machining process because a lot of applications require both aesthetic and functional design. Modern industrial designers have all the right tools and checks to ensure that their designs are functional. So, CNC machining surface finishes is an area where they can cause their product to stand out from the crowd.

The following will discuss the basics of CNC machining surface finishes and sheds some light on the considerations for selecting the right type for any project.

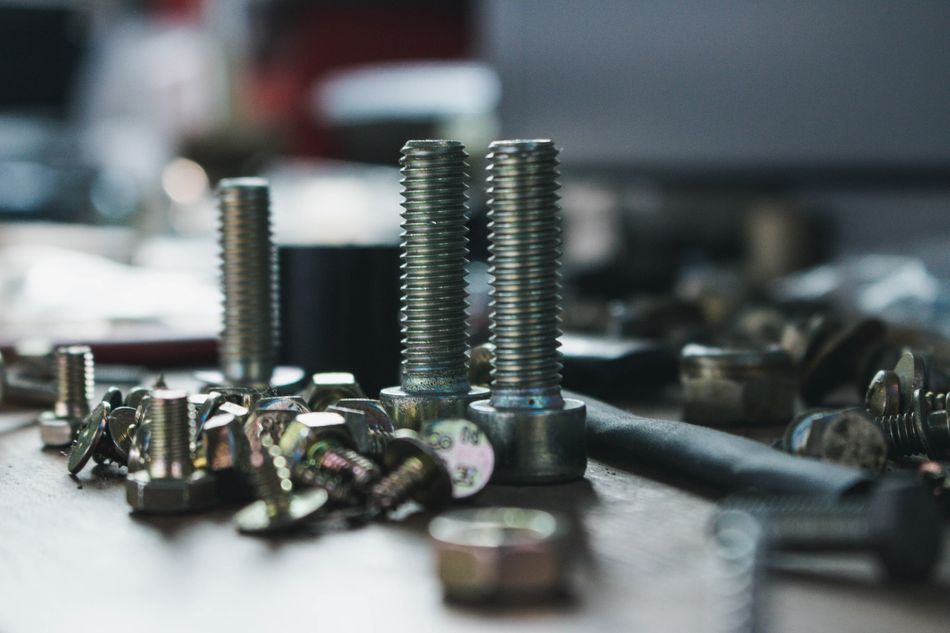

Pre-Surface Finish Processes for CNC Parts

Before discussing the main finishing types for CNC machining, let’s discuss the main pre-finish processes common in the industry. Here’s what they are.

1 – Degreasing

The machining process exposes the workpiece to multiple contaminants like oils, coolants, and other lubricants that reduce heat and friction. The degreasing process removes all those contaminants with different solvents or through ultrasound as well. In some simpler cases, even washing the part can be enough. However, the right process depends on the material properties and overall finishing requirements of the project.

2 – Deburring

This process removes all kinds of sharp edges and protrusions from the workpiece. It is quite important because burrs can negatively impact the performance of the part and can also be a safety hazard.

3 – Grinding

Grinding uses an abrasive wheel to clean the surface and remove any additional material from it. It is an integral process that creates an even and smoother finish, especially for materials that accumulate a lot of contaminants.

4 – Inspection

Once done, the last process is to inspect the part for any defects and rectify any issues if they exist.

Types of CNC Machining Surface Finishes

When it comes to choosing between different types of surface finishes, there are 3 categories that the industry opts for.

The first option is as machined, where the CNC machine itself processes the part for final finishes. Secondly, chemical finishes, where different chemical processes create a protective and aesthetic layer on the surface. Finally, the last process is mechanical finish, where physical processes and materials improve the quality and texture of a specific surface.

Let’s take a brief look at these categories now.

As Machined Finishing

As machined finishing refers to the surface finish that doesn’t need any process after dismounting from the machine. The main characteristics of this surface finish are the visible tool marks and a rough texture. The primary factor determining finishing quality is surface roughness (Ra), which is the average deviation of the machined profile from the ideal surface.

In general, the industry relies on specific Ra values to determine the quality of machined finishes. These values may vary depending on the specific application but typically fall within a certain range. It is important to note that Ra is not the only factor to consider when evaluating the quality of a machined finish, as factors such as surface integrity, waviness, and flatness can also affect the overall quality of the surface finish. The industry relies on the following Ra values:

- 3.2 μm Ra

- 1.6 μm Ra

- 0.8 μm Ra

- 0.4 μm Ra

One of the main advantages of opting for as machined finishing is the dimensional tolerances. The smaller the surface roughness is, the higher the dimensional tolerance would be for that part. Moreover, the machined finish doesn’t incur any additional costs, which is ideal for projects on a tighter budget.

However, machined finishes leave visible tool marks on the workpiece, which is not ideal for high-value projects where aesthetics play an important role as well.

Chemical Finishing

Another common process is to use different kinds of chemical processes to coat the surface and give it an additional layer of protection. These layers also give a better overall appeal to the part because of their color, shine, and other similar attributes. Here are the main types of chemical-based CNC surface finishes:

Anodizing

Anodizing is a chemical process that immerses a part in an electrolyte solution and forms a protective oxide layer on the surface. The anodizing process has two types, type II and type III, where the former is a decorative layer and the latter is a hard coat suitable for high-performance applications. Both type II and type III anodizing use a sulfuric acid bath and electrolysis to create a uniform oxide layer on the surface.

- For type II, the layer remains relatively thin (up to 25 microns) and remains flexible enough for different applications. However, a thinner oxide layer means that the material remains susceptible to abrasions and corrosion after a certain degree of exposure.

- For type III, the anodizing process remains the same except for the requirement of a higher voltage current. The type III process also controls the temperature and maintains it at a lower temperature. This results in a thicker oxide layer (25 to 150 microns) that provides better corrosion and abrasion resistance to the material.

Despite better corrosion and abrasion resistance, type III anodizing is not suitable for some applications. The thicker oxide layer can make the workpiece brittle, which may cause cracks or chips under severe stress. That’s why it’s integral to consider the application before selecting between type II and III anodizing.

After anodizing, the oxide layer protects any part from corrosion and other environmental contaminants. Whereas, the process also resists wear during use. In most cases, especially for aluminum parts, the anodizing layer is the only process for the surface. Moreover, there is a wide range of color options, like black, blue, pink, bronze, and more that enhances the overall aesthetic appeal of the part.

However, the anodizing surface finishing is quite expensive and can increase the overall cost of the part. Besides, anodizing creates an additional layer on the part, which is not suitable for applications with high-precision requirements.

Alodine Coating

Alodine coating, or chromate conversion, is a common process on aluminum and other non-ferrous metals. The process applies a thin chromate coating on the part’s surface which enhances its corrosion resistance and adhesion. Generally, parts with Alodine coating will have another subsequent paint coat to ensure the longevity of the part.

There are, however, some major concerns regarding Alodine coating as well. Firstly, it’s environmentally hazardous and poses a significant safety risk for people working on it. Moreover, the process itself is also very complex and requires extreme precision, which can potentially increase the cost.

Black Oxide Coating

Black oxide coating generally works well with steel, copper, and other alloys that react well with oxygen. It creates a strong oxide layer throughout the part and protects it from different contaminants and physical damage. Apart from the corrosion and wear resistance, black oxide layers also have high lubricity, which is ideal for applications where friction plays a negative role.

Black oxide finishing has a few disadvantages as well. The most important one is its susceptibility to abrasion, which makes it unsuitable for applications with high mechanical stress values. Furthermore, the corrosion resistance is also not that high, which means that the coating will fail in case of constant exposure to harsh conditions.

Overall, black oxide coating is a great CNC surface finish for regular applications. However, it’ll fail in any severe environment as a high degree of contaminants, temperature, and mechanical stresses can cause it to fail.

Electroplating

This is one of the most common surface finishing for CNC parts because of its benefits and versatility. The electroplating finishing deposits a thin metallic layer on the workpiece and protects the inner part from all kinds of contaminants and corrosion.

In addition to its functional benefits, electroplating is also highly valued for its ability to enhance the aesthetic appeal of surfaces. With options such as decorative and satin finishes, electroplating is widely regarded as one of the most attractive finishing options available in the industry. This makes it an ideal choice for applications where aesthetics are a major consideration. Whether you are looking to add visual appeal to a product or enhance the appearance of a component, electroplating can provide an excellent solution.

But electroplating finishing is a highly complex and precise process that requires significant technical expertise and experience for successful application. Additionally, it involves the use of numerous hazardous chemicals and consumes a significant amount of energy, which raises serious environmental concerns. Furthermore, electroplating can only be applied to conductive materials, which limits its application in certain industries. As a result, alternative surface finishing techniques may require non-conductive materials.

Passivation

Passivation is a common post-processing technique used in CNC machining to improve the surface quality and performance of parts. After the machining process, the surface of the part may have micro-roughness or surface impurities that can negatively impact the part’s performance over time. Passivation can help to mitigate these issues.

In CNC machining, passivation is typically performed on stainless steel parts. After machining the parts, they have a thorough cleaning to remove any residual oils, coolants, or metal debris. Then, the parts are immersed in a passivation solution, which can consist of nitric acid, citric acid, or a combination of both.

During passivation, the acidic solution chemically reacts with the surface of the part, removing any surface impurities and creating a uniform oxide layer. This oxide layer helps to protect the part from corrosion and other environmental factors. The passivation process typically takes several hours to complete, depending on the size and complexity of the part.

Mechanical Finishes

Another category of surface finishing requires mechanical processes to complete. In such cases, the workpiece is subjected to multiple stresses and abrasions to obtain the finished product. In most cases, mechanical finishes don’t need any post-processing but there are some options like paint or other coats that can increase the longevity and durability of the part.

Here are a few common types of mechanical finishes for CNC parts:

Bead Blasting

Bead blasting involves propelling spherical beads of glass or ceramic on the surface of the part. The process results in a textured, matte finish that can mask surface imperfections and create a uniform appearance. It also removes all kinds of contaminants because of the high-pressure air and maintains the overall cleanliness of the part. This process is important as contaminants can hinder subsequent processes like paint and electroplating.

While safe, bead blasting can potentially cause a lot of surface damage to the part in case of a mistake. The process also affects the dimensional accuracy and functionality of the part and has high associated costs. Thereby making it a viable choice for luxury items or expensive parts only.

Powder Coating

Powder coating is perhaps the most common surface finish for metallic parts. One of the main reasons behind it is its durability and versatile performance. Powder coats resist scratches, and chips, and don’t fade with time. Moreover, it comes with a wide variety of colors to give designers more freedom and offer better aesthetics. Finally, the process itself is extremely environment-friendly, which makes it an ideal choice for a lot of applications.

While powder coating offers many benefits, there are some potential disadvantages to consider. One of the main drawbacks is the high initial cost of equipment and materials, which makes it a more expensive option for smaller production runs or one-off parts. Additionally, the curing process requires high temperatures, which can limit the types of materials and applications.

Brushing

Brushing is more of a surface treatment method rather than a surface finish because it’s mostly used to prepare the workpiece for the next finishing process. The brushing finishing process is exactly as it sounds where a metal-wire brush or other abrasive pad cleans the surface and physically removes any contaminants or particles on the surface. One of its main advantages is its simplicity as the process doesn’t need any technical skill or machines to carry out.

However, brushing can potentially damage the surface if one is not careful. Similarly, the process also can’t handle complex parts and is only done manually, which consumes a lot of time.

Polishing

Polishing is a simple process of making any surface smooth by using the concept of abrasion. Generally, the process starts with the coarsest abrasive and then advance until a smooth, aesthetically pleasing surface finish remains.

Moreover, polishing can also improve the durability of the material by reducing the risk of cracking or chipping. However, all that comes at a cost. Polishing is an extremely time-consuming process and can cost a lot too. Especially in the case of complex geometries, the requirements skyrocket because special skills and equipment are needed to polish unusual shapes to perfection.

Painting

Metal paints are an effective CNC surface finish that provides protection against corrosion by covering the entire surface. They typically utilize lacquer and polyurethane to shield the surface from exposure to water and contaminants, resulting in long-lasting protection. However, when faced with harsher chemicals and abrasions, the paint can fail as it peels away, exposing the underlying surface.

Painting is a versatile process that offers a wide range of colors and finishes, making it an attractive option for many CNC machining applications. The process is also relatively straightforward. Nevertheless, it can be detrimental to the environment in certain cases and may require significant drying time for proper adhesion.

Factors to Consider When Choosing a CNC Machining Surface Finish

Choosing the right surface finish for a CNC machined part is important to ensure that the part meets the desired functional and aesthetic requirements. Some of the key factors to consider when selecting a CNC machining surface finish include functionality, material, aesthetics, cost, lead time, environmental impact, and part geometry.

By carefully evaluating these factors, the surface finish that perfectly matches the requirements of a specific project can be selected:

- Functionality: The surface finish should be selected based on the functional requirements of the part. For example, parts that require high wear resistance or corrosion resistance may require a stronger surface finish like anodizing or electroplating. Similarly, parts that need to be aesthetically pleasing will need a different surface finish with multiple color and texture options.

- Material: Certain CNC surface finishes are better suited to specific CNC materials than others. For example, anodizing is typically used on aluminum parts, while electroplating is suitable for conductive metal parts.

- Aesthetics: The surface finish should be selected based on the desired appearance of the part. Different surface finishes can produce a range of visual effects, such as high gloss or matte finish.

- Cost: Some finishes may be more expensive than others. For instance, powder coating will be a lot more expensive than regular paint. So, it’s important to balance all parameters to costs, function, and time to get the most optimum surface finish.

- Lead time: Different finishing methods require varying amounts of time to complete. For example, if you need a product quickly, you may need to choose a finishing method that can be completed quickly, such as polishing. However, if you have more time and need a higher-quality finish, you may want to choose a method like anodizing, which can take longer but provide a more precise and polished finish.

- Environmental impact: It is important to consider the environmental impact of the surface finish process and explore eco-friendly options whenever possible.

- Part geometry: The geometry of the part can also affect the choice of surface finish. For example, parts with tight tolerances may require a different finish than parts with a more forgiving design.

Choose the Right Surface Finish with RapidDirect

The overall appearance and aesthetics of the final product in CNC machining are as important as functionality. The right surface finish can save the material from environmental contaminants, preserve the material, and enhance its overall aesthetic appeal.

Generally, these processes are simple, but there is little room for mistakes as the finishing is the last production step in many cases. So why not leave the process to professionals who have all the right tools and experience to get your job completed splendidly?

RapidDirect has a long and successful history of delivering exceptional products to its customers in the shortest time and at the most competitive rates. Our expert team can provide different finishing options and even recommend the best choice depending on your application and requirement. That’s not all, you can do all of that with only a few clicks at your home or office. Simply head over to our website, and enter your project details. And wait for us to get back to you with a quote.