Fast and Repeated Production with Metal 3D Printing

In manufacturing, the ability to quickly produce high-quality components on demand is critical. While metal 3D printing is often associated with producing unique, complex parts, its potential for serial production is frequently overlooked.

In manufacturing, the ability to quickly produce high-quality components on demand is critical. While metal 3D printing is often associated with producing unique, complex parts, its potential for serial production is frequently overlooked. This case study of the driver component for the BOLDseries by One Click Metal demonstrates how metal additive manufacturing can effectively meet the challenge of producing components quickly and repeatedly, offering a viable alternative to traditional manufacturing methods that rely heavily on external suppliers.

The Challenge: Quick and Frequent Production with Limited Supplier Reliance

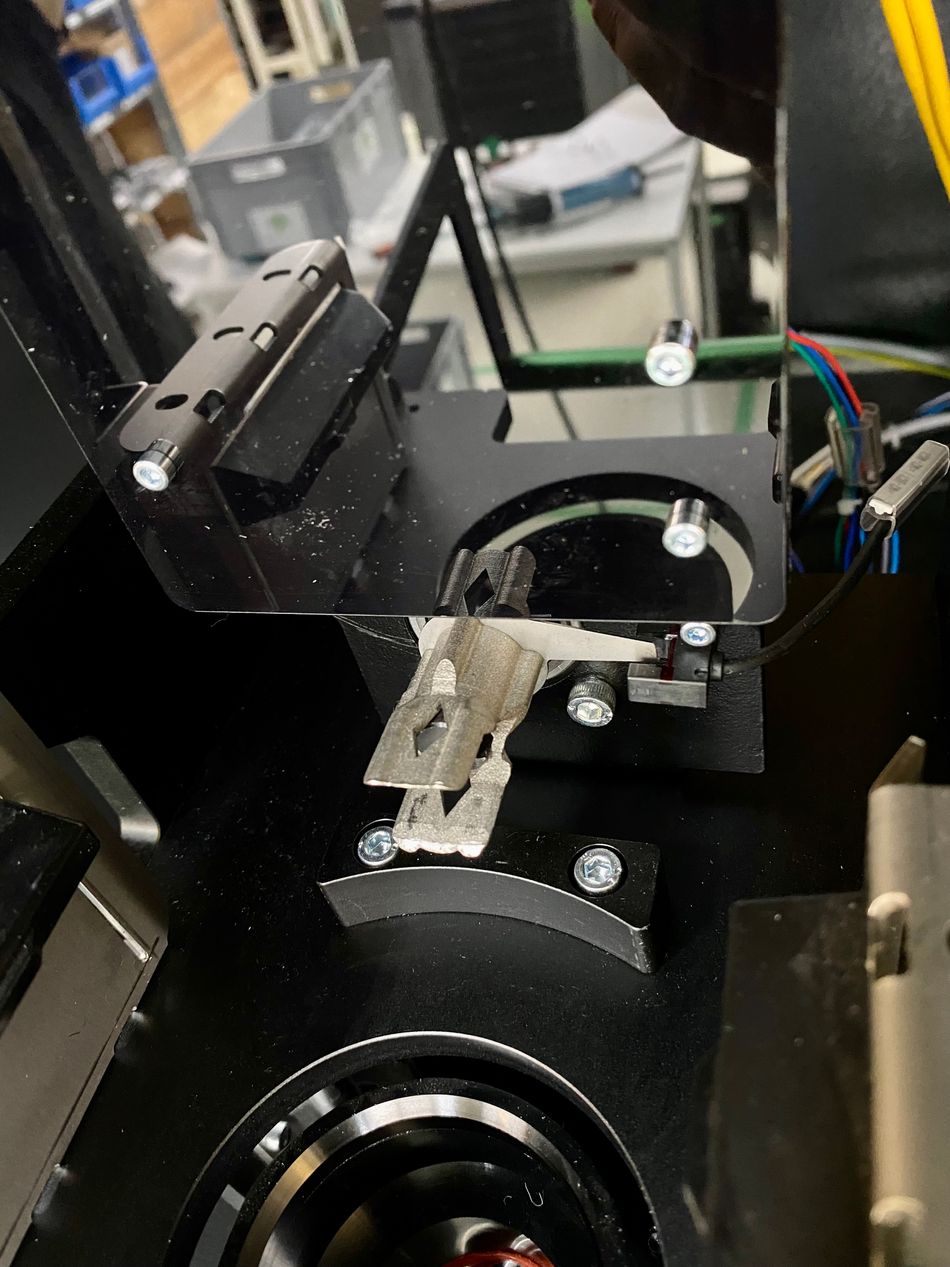

One Click Metal faced a pressing need to produce a large quantity of driver components for their BOLDseries metal 3D printer. The driver is a key part responsible for opening and closing the powder-filled cartridges, and it needed to be produced with precision and durability. Traditionally, these parts would be manufactured through CNC machining, which, while reliable, comes with significant drawbacks—especially when rapid production is required. Outsourcing to suppliers often leads to long lead times, high costs, and the need to order in large quantities to make production cost-effective. This dependency on external suppliers can cause delays and hinder a company’s ability to respond quickly to demand.

The Solution: Metal 3D Printing for Fast and Flexible Production

To address these challenges, One Click Metal turned to their in-house Laser Powder Bed Fusion technology. By utilizing metal 3D printing, they were able to produce the driver components much faster and with greater flexibility than traditional methods would allow. This approach eliminated the long lead times typically associated with external suppliers, allowing the company to quickly produce the parts they needed, when they needed them.

A significant advantage of using metal 3D printing in this scenario was the ability to maximize production efficiency. By stacking 144 drivers on a single build plate, One Click Metal could produce a large batch of components in just over 60 hours. This capability not only met the immediate production needs but also reduced the cost per part to €11.05—a significant savings compared to traditional manufacturing costs.

Benefits of Metal 3D Printing in Meeting Production Demands

Rapid Production: Metal 3D printing enabled One Click Metal to produce a large number of components quickly, without the delays associated with traditional supply chains. This allowed the company to respond swiftly to production needs.

Cost Efficiency: By producing the parts in-house and utilizing the full build volume of the printer, the cost per driver was significantly reduced, making metal 3D printing a cost-effective option even for serial production.

Supply Chain Independence: With the ability to produce components on-demand, One Click Metal reduced its reliance on external suppliers, which is particularly beneficial when quick turnarounds are required.

Material and Design Efficiency: The LPBF process allowed for precise control over material usage, reducing waste and enabling the production of lightweight, optimized designs that still met all functional requirements.

Conclusion: Metal 3D Printing as a Versatile Manufacturing Tool

The production of the driver component for the BOLDseries is a clear example of how metal 3D printing can be effectively used not only for unique, complex parts but also for the quick, repeated production of essential components. By leveraging this technology, manufacturers can gain greater control over their production processes, reduce dependency on suppliers, and achieve cost and time savings. Metal 3D printing proves to be a versatile tool that can meet a wide range of manufacturing needs, including those that require speed and flexibility.