Harnessing Manufacturing Intelligence to Enhance Operational Excellence in Aerospace

Explore how advanced solutions in manufacturing intelligence are transforming aerospace manufacturing by addressing key challenges in design, production, and quality control while promoting sustainability.

Precision, efficiency, and adaptability have always been essential in aerospace manufacturing. Today, simulations, digital twin technology, and real-time monitoring are not only helping companies meet these goals but also bringing them closer to carbon neutrality.

To drive these innovations, companies require insights into every aspect of the manufacturing process. This is where Hexagon steps in, offering end-to-end workflow solutions to tackle key challenges across design, production, and quality control, with sustainability at the forefront.

Current Challenges and Opportunities in Aerospace Manufacturing

Aerospace manufacturers face the challenge of creating complex parts while adhering to strict regulations. Additionally, they aim to reduce waste as part of their sustainability goals. To meet these demands, the industry requires advanced, integrated solutions to streamline production.

Design and engineering

In aerospace design, simulations allow engineers to test for safety and performance without the repeated need for prototypes. This not only reduces costs but also makes the development process significantly less wasteful.

However, running complex simulations requires powerful computing infrastructure. Without the right infrastructure and expertise, many design teams still rely on the more costly approach of prototype testing. This often leads to delays and added expenses in the development cycle.

Production

One of the most prominent challenges is long setup times. Aerospace manufacturing involves intricate parts with each production run often requiring recalibrations and adjustments. Machine breakdowns is another well-known issue that can disrupt production.

Additionally, maintaining consistent quality across multiple production sites is also a hurdle. Due to strict safety standards in aerospace, even minor deviations lead to additional quality checks, which can further slow down production. The industry also faces a shortage of skilled labor.

Quality control

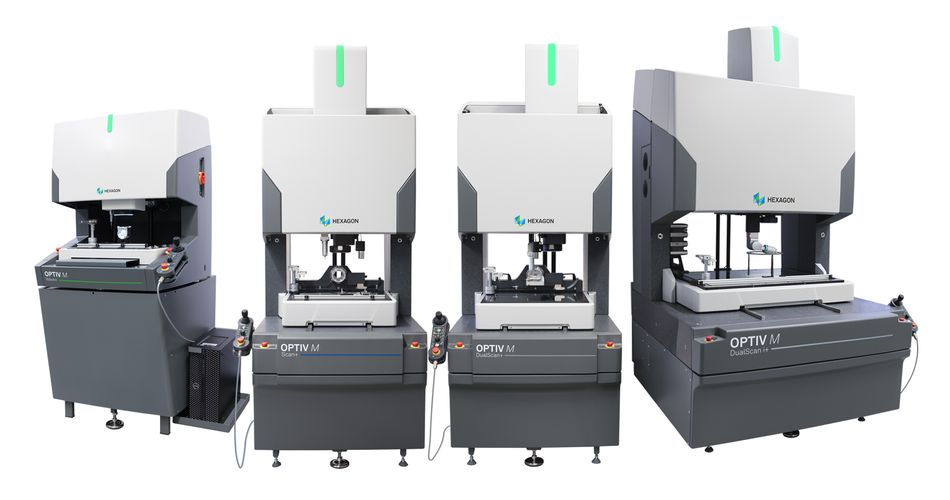

Coordinate Measuring Machines (CMM) are crucial for checking the accuracy of aerospace components. However, this process can be time-consuming, especially considering that parts need to be brought to these machines and may require multiple passes. The lack of real-time insights adds to this issue. Without immediate access to measurement data, it becomes challenging for engineers and technicians to detect and address deviations in production early on.

Manufacturing Made Intelligent

Hexagon is a global leader in digital reality solutions, offering integrated manufacturing intelligence that spans from design to final product. The company’s goal is to make advanced technology accessible on the shop floor to ensure consistent quality throughout the process. Hexagon has supported top brands and organizations, including Formula 1’s Red Bull Racing, the cutting-edge research of CERN, and automotive giant Volkswagen. Its core offerings are as follows:

Complete integration

Hexagon provides comprehensive integration across the entire aerospace production cycle, spanning design, manufacturing, and quality control. This seamless integration allows data to move freely across each stage and system, creating transparency that enables stakeholders to monitor progress at every step. With actionable insights coming from each phase, aerospace teams can make the right decisions that improve overall efficiency and product quality.

Simulation and optimization

Hexagon’s Computational Fluid Dynamics (CFD) solutions help aerospace engineers simulate and analyze the aerodynamic forces acting on aircraft components. This allows companies to fine-tune designs without the need for physical prototypes at each iteration. Furthermore, Hexagon's data-driven approach enables teams to pinpoint bottlenecks and improve process efficiency, which leads to more sustainable production.

Real-time monitoring

Hexagon’s real-time monitoring solutions bring machine and production data directly to engineers and operators through easy-to-read dashboards. This real-time accessibility enables better communication and collaboration between teams, while continuous monitoring enables predictive maintenance, reducing downtime by identifying potential issues before they escalate.

Ensuring Smart Design, Intelligent Production and Integrated Quality Assurance

Smart Design for Aerospace Engineering

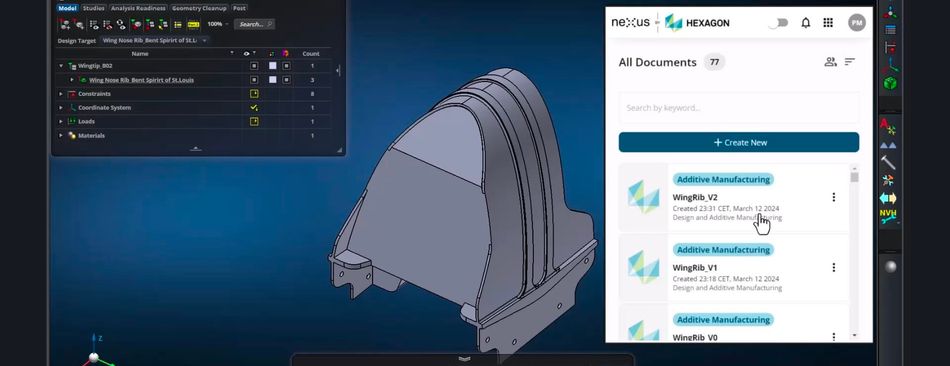

Hexagon offers a cloud-based simulation tool Nexus Compute. Supporting various technologies including scFLOW, it enables engineers to test their designs for aerodynamic stress including hypersonic conditions. The cloud-based nature of the tool ensures that stakeholders from different teams can collaborate seamlessly. Hexagon's solutions also come with Integrated Computational Materials Engineering (ICME) for virtual material testing.

Intelligent Production for First-Time-Right Manufacturing

Hexagon’s real-time monitoring solutions provide manufacturers with continuous insights into workflow efficiency, enabling engineers to catch potential issues before they lead to costly delays.

With digital twin technology, Hexagon takes monitoring to another level by creating virtual replicas of physical equipment. It gives manufacturers a real-time view of machinery performance and its wear patterns paving the way for predictive maintenance.

Integrated Quality Assurance

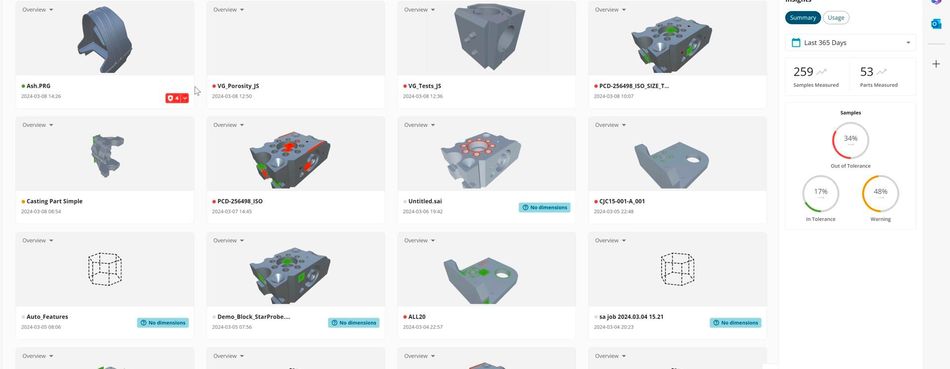

Hexagon offers in-process measurement, a system that measures and monitors parts or components during production. By integrating measurement tools directly into the production stage, manufacturers can detect and address defects early in the cycle, significantly reducing waste.

Hexagon’s centralized data and documentation platform also ensures that information is easily accessible across teams. This facilitates traceability and better decision-making across the shop floor. Additionally, this approach streamlines processes for regulatory compliance and supports consistent quality across operations.

Real-World Application: Aeroplane Wing Nose Rib Case Study

The aeroplane wing nose rib is a critical structural element that withstands intense aerodynamic forces while maintaining minimal weight. Getting it right with traditional methods is a time-consuming affair. However, with its end-to-end workflow solutions, Hexagon helped the client optimize every stage of the production cycle. Let’s find out how its advanced manufacturing intelligence helped streamline operations, reduce costs, and minimize waste to support sustainability.

Design Optimization

Using Hexagon’s CFD and system dynamics, the team tested their designs in high-speed flow simulations. Through tools such as scFLOW, engineers were able to simulate high-speed flow conditions, including extreme phenomena like shockwaves. This virtual testing accurately gauged load behaviors and aerodynamic stresses, allowing engineers to evaluate multiple configurations and zero in on the one that meets stringent performance requirements before moving on to the prototyping phase.

Manufacturing Preparation and Verification

In preparation for manufacturing, the client used Hexagon's digital twin technology to ensure precise alignment between design specifications and production processes. Through CAD modeling and direct "Send To CAM" interoperability, engineers ensured compatibility between design and manufacturability. Digital twins allowed for accurate simulation of material and process interactions, ensuring that each step adhered to high-quality standards with minimal operator intervention.

Shop-Floor Operations and Quality Inspection

With in-machine measurement solutions and portable machines ready for the shop floor, the team was able to collect measurement data without delays. Hexagon's first-time-right machining approach minimized revisions and significantly reduced material waste. Hexagon’s in-machine inspection capabilities enabled real-time measurement of components, ensuring adherence to design tolerances. The integration of CMM allowed the client to capture high-precision measurements for geometric and free-form features. Portable machines equipped with various high-speed sensors enabled continuous quality assurance, minimizing waste and accelerating the process.

Reporting and Analytics

Key Benefits of Manufacturing Intelligence:

With its digital twins, simulation, and optimized workflows, Hexagon can help aerospace manufacturers accelerate product development. In the past, its clients have achieved up to a 30% reduction in time from concept to production.

With Hexagon’s virtual testing tools, the need for physical prototypes is minimized. This can mean up to a 50% reduction in cost for aerospace companies compared to traditional methods.

The company’s manufacturing intelligence solutions can improve “first-time-right” production rates. This reduces the need for rework saving time and resources.

Through real-time monitoring and predictive maintenance, Hexagon maximizes machine uptime and productivity.

A focus on quality control means Hexagon’s solutions help manufacturers comply with industry standards more reliably while also supporting sustainability by reducing waste.

Digital documentation offers complete traceability across the product lifecycle. This ensures compliance with regulatory requirements and industry standards with more confidence.

The aerospace industry faces complex challenges in various production stages. For instance, access to advanced simulation tools is often limited. On the production floor, long setup times are common, and maintaining consistent quality across facilities is a struggle. Precision measurements CMMs is crucial but can often become bottlenecks in the workflow.

Did you miss it? Watch Wevolver's reporting from Hexagon Live in Eindhoven on-demand

Hexagon’s manufacturing intelligence suite addresses these challenges with its end-to-end solutions. Their cloud-based simulation tools enable engineers to run essential design tests faster and more collaboratively. By providing real-time monitoring throughout production, Hexagon helps manufacturers achieve consistent quality and reduce waste. Additionally, Hexagon speeds up the traditionally slow CMM measurement process by integrating measurement tools directly into the production stage.

Throughout the event, Wevolver was reporting live on our social media channels from the center of the action on Day 1, which saw an engineering marvel in the form of Max Verstappen’s 2021 championship-winning car, showcased by Oracle Red Bull Racing and the grand opening of Hexagon's brand new 400 square meters Experience Center.