High-Performance MOSFETs Driving Excellence and Innovations in Automotive Electronics

Nexperia's automotive MOSFETs enhance innovation across both traditional and electric vehicles, expertly managing a wide array of applications from simple lighting to advanced electrification systems, ensuring high performance, reliability and superior efficiency in every aspect.

Introduction

In modern automotive engineering, Metal Oxide Semiconductor Field Effect Transistors (MOSFETs) are fundamental components that enhance the performance, efficiency, and safety of vehicle electronics. Serving as key components in power management systems, motor controls, safety mechanisms, and various other vehicle subsystems, the reliability and performance of MOSFETs significantly impact the efficiency, safety, and overall driving experience of both electric vehicles (EVs) and internal combustion engine (ICE) vehicles. Consequently, the quality of MOSFETs is a non-negotiable aspect.

This article provides a detailed look at high-performance MOSFETs tailored for automotive applications, focusing on their essential functions, performance metrics, and rigorous quality standards. Additionally, it examines Nexperia's contributions to the evolution of the technology, highlighting real-world applications and discussing the trends currently shaping the industry.

Understanding Automotive MOSFETs

MOSFETs are pivotal components in the architecture of modern automotive electronics. Their ability to efficiently switch and amplify power makes them a critical component across various systems within vehicles.

Function and Importance of MOSFETs in Automotive Systems

MOSFETs are integral to the functionality of numerous automotive systems, serving as critical components in power management and signal processing across various applications. Their ability to handle high currents and voltages efficiently while switching and amplifying signals makes them a vital electronic component in modern vehicles. Here’s a closer look at some specific applications:

Powertrain and Vehicle Dynamics:

Advanced Driver Assistance Systems (ADAS) radar sensor module: MOSFETs regulate the power distribution to the radar components of ADAS, ensuring optimal performance by managing the precise control of high currents needed for the radar's operation.

Electronic Power Steering (EPS): MOSFETs modulate the power supplied to the electric motor that drives the steering mechanism, allowing for precise control and responsiveness, enhancing both the efficiency of steering operations and the overall safety and comfort for the driver.

Anti-locking braking systems/Electronic Stability Control (ABS/ESC): Critical in providing the rapid switching needed for effective electronic stability control and braking systems.

Vehicle Comfort and Convenience:

Adaptive Front LED lights and Interior LED lighting: MOSFETs drive the lighting systems, offering precision control that adapts to varying conditions and user settings.

Automatic Heating Ventilation and Air Conditioning (HVAC): Ensures efficient motor control for heating, ventilation, and air conditioning, enhancing passenger comfort.

Active Suspension System: MOSFETs facilitate the rapid adjustment of suspension settings to adapt to road conditions to improve ride quality and vehicle handling. This technology contributes to a smoother driving experience by dynamically managing the suspension's response to changes in terrain.

Safety Systems:

Airbag controller with Safing MOSFET: Controls the deployment of airbags in a crash situation, ensuring timely and reliable activation.

Seat Belt Pretensioners and Force Limiters: MOSFETs control the mechanisms that tighten seat belts instantly during a collision, reducing slack to protect occupants. They also regulate the force limiters to ensure that the belt tightens adequately without causing injury, enhancing passenger safety during severe impacts.

Power Management in EVs/Hybrids:

High power, high-efficiency DC/DC converter and On-Board Charger (OBC): Essential for converting and managing power within the vehicle’s electrical system, crucial for electric and hybrid vehicles.

Zonal Control Units: MOSFETs facilitate intelligent power distribution controlled by software, optimizing the delivery of power to different zones of the vehicle. This not only enhances the efficiency of electrical systems but also supports advanced features such as customized lighting and climate control across different cabin areas.

Battery Management System (BMS): MOSFETs play a crucial role in managing systems that monitor and control battery packs, crucial for EV performance and safety. They also help in the balanced charging of battery cells, a process that is critical for maintaining the health and extending the lifetime of the battery. By ensuring each cell within the battery pack is charged correctly, MOSFETs prevent overcharging and help maintain the overall battery balance, thus safeguarding and maximizing battery life.

Applications in ICE vehicles:

Cooling Fan and Fluid Pump Controls: Manage the operation of cooling systems and fluid circulation, which are vital for maintaining the operational integrity of engine and battery systems.

Electronic Fuel Injection: Improves the efficiency and control of fuel delivery to the engine, optimizing performance and reducing emissions.

MOSFETs’ versatility enables them to support these (and many more) critical functions across various systems within the vehicle, highlighting their importance in the automotive industry.

Key Performance Metrics for MOSFETs

The high performance, efficiency, and reliability of MOSFETs in automotive applications are essential for ensuring the smooth operation of vehicle electronics. These metrics include:

Electrical Efficiency:

Switching Efficiency: Effective switching speeds for automotive power MOSFETs typically range from tens to hundreds of nanoseconds, essential for fast response times in power-intensive applications. Small signal MOSFETs, which are also qualified for automotive use, can switch in just a few nanoseconds, providing even faster response for applications requiring high-speed signal processing.

On-state Resistance: Lower on-state resistance increases efficiency by reducing power losses. Typical values range from 10 mΩ to sub <1mΩ, ideal for minimizing heat generation and energy wastage.

Power Limits: These are determined by the maximum voltage and current the MOSFET can handle—commonly between 5V to 100V and 10A to 2000A—suitable for a variety of automotive functions.

Thermal Performance:

Operating Temperature Range: Automotive MOSFETs must operate effectively within a range of -55°C to +150°C, with short-term tolerance of up to 175°C for high-heat environments such as engine compartments.

Thermal Resistance of Junction-Base Mounting: This parameter, ranging from 0.5K/W to 2K/W, indicates the capability of heat dissipation. Lower values are preferable, as they denote superior thermal management.

Durability and Longevity:

Thermal Cycling Resistance: MOSFETs are designed to withstand numerous thermal cycles without performance degradation, ensuring long-term reliability. Additionally, they must pass rigorous electrical bias stress tests, including high temperature gate bias, high temperature reverse bias, and humidity bias stress. These tests are critical for assessing the durability of MOSFETs under severe environmental conditions and electrical stresses, further ensuring their robustness and suitability for demanding automotive applications.

Suggested reading: Next-generation MOSFET technology Meets Demand for Strong Thermal Performance in Automotive Applications.

Quality Standards and Certifications

MOSFETs used in automotive applications are subject to specific industry standards that dictate their design, testing, and performance criteria. One of the most critical standards is the AEC-Q101, a stringent specification from the Automotive Electronics Council that covers stress tests for semiconductors in automotive applications. This standard ensures that MOSFETs can withstand extreme conditions such as high temperatures, vibrations, and varying electrical loads.

Compliance with AEC-Q101 involves multiple tests, including thermal shock, moisture resistance, electrostatic discharge susceptibility, and life-cycle testing. These tests are designed to simulate the actual operating conditions that MOSFETs will face in a vehicle, ensuring that only the most robust components make it into automotive systems.

Suggested reading: Semiconductor Resilience with Innovations in Testing Techniques and Packaging

Trends and Innovations

The automotive industry is on the brink of a big technological transformation, with MOSFETs playing a crucial role in shaping the future of mobility. As the demand for EVs and autonomous driving systems increases, MOSFETs are evolving to meet the new challenges and performance requirements.

New materials such as Silicon Carbide (SiC) and Gallium Nitride (GaN) are making their way into MOSFET design. These materials offer superior efficiency, higher breakdown voltage, higher temperature tolerance, and faster switching capabilities than traditional silicon MOSFETs, making them ideal for the high-power demands of EV powertrains and charging systems.

Additionally, the integration of intelligent control features within vehicle subsystems is becoming more common. Smart power converters can provide real-time diagnostics and protection features, enhancing the overall safety, reliability and repairability of automotive electronics.

Moreover, as vehicles become more connected and autonomous, the number of electronic components and systems is set to increase continuously, necessitating MOSFETs that can perform reliably in a more crowded and interconnected environment. The ongoing development in MOSFET technology also aims to reduce interference and improve communication between components, ensuring seamless operation.

Nexperia's High-Performance MOSFETs: Driving Excellence and Innovation in Automotive Electronics

Nexperia distinguishes itself in the automotive electronics market with a strong focus on quality, performance, and innovation. As a semiconductor manufacturer, Nexperia is committed to developing MOSFET technology that meets the stringent requirements of modern automotive systems.

Innovative Product Range

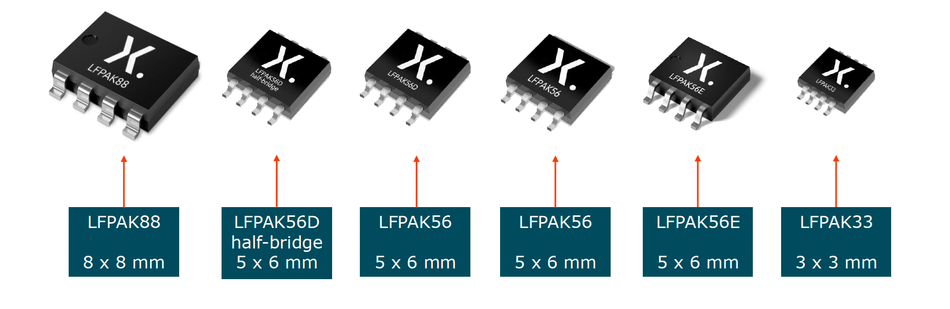

Nexperia’s automotive MOSFET product portfolio contains over 400 types of power MOSFETs, with specifications ranging from -18 to 500 A for drain currents and drain-source voltage ratings ranging from -60to 100 V. These are housed in robust copper-clip packages featuring cutting-edge technologies, such as flexible leads and wettable flanks for ease of Automatic Optical Inspection (AOI) and improved reliability. This diversity ensures solutions for every automotive electronic need, from simple lamp circuits to complex power requirements of vehicle electrification and hybrid battery systems.

Suggested reading: A story of innovation: How LFPAK revolutionized an industry.

Focused on Future Needs and Sustainability

Nexperia is further advancing MOSFET technology with initiatives like the introduction of the 1200 V Silicon Carbide MOSFETs, which enhance efficiency and reduce energy waste—crucial for extending the driving range of EVs. The company's efforts in scaling down MOSFET sizes allow for more compact system designs without compromising performance or reliability. These innovations support the automotive industry’s goals of reducing carbon footprints and advancing sustainable mobility solutions.

Specialization for Reliability

Tailoring MOSFET offerings to specific automotive needs ensures that each component delivers optimal performance and efficiency. Nexperia’s MOSFETs are essential in systems ranging from adaptive lighting and climate control to critical applications like electric power steering and braking systems. Innovations in packaging and silicon technologies enhance thermal performance and durability, vital attributes where reliability and space economy are most important.

Nexperia upholds a zero-defect culture, which has been recognized through multiple supplier awards, reflecting their commitment to excellence. Impressively, the company has maintained a complaint rate of less than 0.05 complaints per million since 2019, emphasizing their relentless focus on quality.

In addition to these innovations, Nexperia provides next-generation support tools for automotive engineers. Their interactive datasheets allow real-time adjustment of parameters like voltage, current, and temperature, instantly visualizing MOSFET behavior. This streamlines design workflows by eliminating manual calculations and circuit simulations. Advanced electrothermal MOSFET models also enable early-stage validation of circuit designs, helping identify EMI and EMC issues upfront.

Nexperia's ongoing innovations and focus on quality support automotive manufacturers in developing more efficient, reliable, and cost-effective electronic systems. These advancements contribute to vehicles that offer improved safety, comfort, and environmental performance.

Visit Nexperia's official website to explore a range of advanced MOSFET solutions built for automotive electronics.

Conclusion

Nexperia's ongoing commitment to innovation in MOSFET technology highlights the critical role these components play in improving vehicle performance, efficiency, and safety. By leveraging advanced materials and innovative designs, Nexperia ensures that automotive electronics meet stringent contemporary standards and are equipped for the evolving demands of tomorrow. As the shift towards more electric and autonomous vehicles continues, the need for reliable, efficient, and high-performance MOSFETs becomes increasingly apparent.

References

[1] Nexperia. Driving solenoids in automotive applications Rev. 1.1 [Internet]. 3 Nov 2023. Available from: https://assets.nexperia.com/documents/application-note/AN50003.pdf

[2] Nexperia. MOSFET and GaN FET Application Handbook [Internet]. 19 Nov 2020. Available from: https://efficiencywins.nexperia.com/efficient-products/mosfet-and-gan-fet-application-handbook

[3] Nexperia. Selection Guide: Discrete, MOSFET and GaN FET components, analog & logic ICs [Internet], Available from: https://assets.nexperia.com/documents/selection-guide/Nexperia_Selection_guide_2023.pdf