How additive printing is changing the face of customized products

Additive printing, commonly known as 3D printing, has rapidly emerged as one of the most transformative technologies in manufacturing. By allowing manufacturers to build objects layer by layer, this technique has revolutionized the way products are designed, produced, and customized.

This article was first published on

xtpl.comHow additive printing is changing the face of customized products

Additive printing, commonly known as 3D printing, has rapidly emerged as one of the most transformative technologies in manufacturing. By allowing manufacturers to build objects layer by layer, this technique has revolutionized the way products are designed, produced, and customized. The capability of additive printing to offer mass customization at scale has redefined traditional manufacturing methods, making it possible to create individualized products that cater to the specific needs and preferences of consumers.

Introduction to Additive Printing and Customized Production

Additive printing has come a long way since its inception in the 1980s. Initially, it was used primarily for rapid prototyping, but as the technology advanced, it evolved into a full-fledged manufacturing solution. Unlike traditional manufacturing, which relies on subtractive processes (such as cutting or milling), additive printing constructs products layer by layer, using digital models. This process allows for greater flexibility in design and significantly reduces waste. Barring a short period in the early 2010s, 3D printing hasn’t been deeply popular with general consumers. That said, the market for commercial 3D printing is now booming.

One of the most profound impacts of additive printing is its ability to enable mass customization. Traditional manufacturing methods require expensive molds and tooling, making customization costly and time-consuming. Additive printing, on the other hand, allows for cost-effective production of small batches or even single customized items, eliminating the need for specialized tools. This makes it possible to create tailored products, from healthcare devices to fashion accessories, at a fraction of the cost and time required by traditional methods.

Key Technologies Behind Additive Printing

Several key technologies drive the additive printing revolution. Each has its own strengths, depending on the materials, precision, and applications involved. Some of the most commonly used additive printing technologies include:

- Fused Deposition Modeling (FDM): FDM is one of the most widely used 3D printing techniques. It works by melting a thermoplastic filament and depositing it layer by layer. FDM is popular for its affordability and ability to print with a wide range of materials, making it suitable for prototyping and creating custom consumer goods.

- Stereolithography (SLA): SLA uses a laser to cure liquid resin into solid layers. This method is known for its high precision and smooth surface finish, making it ideal for applications that require fine details, such as dental and medical devices.

- Selective Laser Sintering (SLS): SLS uses a laser to fuse powdered material layer by layer. It allows for greater material flexibility and can produce more complex designs than FDM. SLS is commonly used in industrial applications where material strength and durability are crucial.

These technologies have become increasingly accessible and versatile, allowing for a wide range of applications in different industries. Additionally, the use of digital design and modeling software enhances the potential for customization, enabling designers to create highly detailed and unique products tailored to individual needs.

Revolutionizing Product Customization with Additive Printing

Additive printing has revolutionized product customization in several industries, enabling the creation of products that were previously difficult or impossible to manufacture using traditional methods. Some of the most impactful applications include:

- Healthcare: Additive printing has made significant strides in healthcare, particularly in the production of customized prosthetics and implants. By scanning a patient’s body, doctors can create custom-fitted prosthetics that offer greater comfort and functionality. In addition, 3D-printed dental aligners and hearing aids are now widely available, providing patients with tailored solutions.

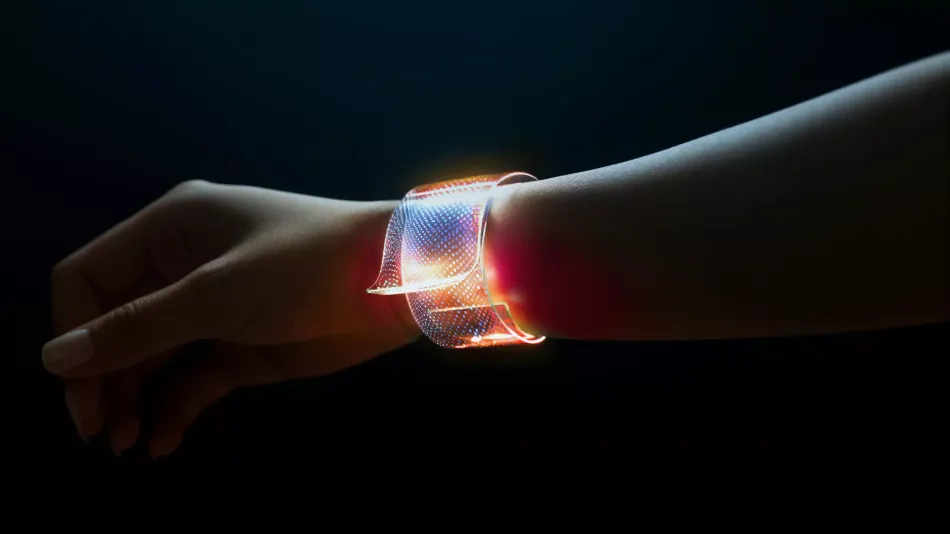

- Fashion: In the fashion industry, additive printing has enabled the creation of wearable technology and custom-fit accessories. Designers can now create intricate, personalized pieces, from jewelry to shoes, that fit individual preferences and measurements. This has opened new opportunities for designers to experiment with unique forms and materials that were not feasible with conventional manufacturing methods.

- Consumer Goods: Custom-fit earphones, eyewear, and other consumer goods are now commonly produced using additive printing. By allowing for precise customization, manufacturers can cater to the specific needs of consumers, offering better comfort, performance, and aesthetics.

Additive printing offers several key benefits for customization, including reduced waste, shorter production cycles, and the ability to produce complex designs that are unachievable with traditional methods. However, there are still challenges, such as material limitations, quality control, and cost efficiency, that manufacturers must overcome to fully capitalize on the potential of additive printing for mass customization.

The Impact of Additive Printing on Supply Chains and Retail

The rise of additive printing has the potential to reshape supply chains and retail models. Traditionally, manufacturers have had to produce large quantities of products in advance, leading to excess inventory, storage costs, and the risk of unsold goods. Additive printing offers a solution to these issues by enabling on-demand production. This means that products can be printed as needed, eliminating the need for large inventories and reducing lead times.

In addition, additive printing allows for more localized production. Instead of relying on centralized factories, companies can establish smaller, decentralized manufacturing hubs closer to consumers, reducing shipping times and costs. This shift towards a made-to-order approach could significantly alter traditional retail models, allowing consumers to order customized products directly from manufacturers or even print products at home using personal 3D printers.

However, integrating additive printing into existing production and distribution systems will require careful planning. Companies must consider how to maintain quality control, ensure cost efficiency, and manage the complexities of producing a wide range of customized products.

Future Trends and Developments in Additive Printing for Customization

The future of additive printing for customization is bright, with emerging materials and technologies set to enhance its capabilities further. Researchers are developing new materials, such as bio-based polymers and advanced metals, which will expand the range of products that can be customized through additive printing. These materials will offer improved performance, durability, and environmental sustainability.

AI and machine learning are also poised to play a key role in optimizing the additive printing process. By analyzing data from previous prints, AI can help optimize designs, reduce errors, and improve production efficiency. Machine learning algorithms can also assist in predicting material behavior, further improving the quality and consistency of customized products.

Looking ahead, the widespread adoption of additive printing for customization could have far-reaching implications. It may lead to more sustainable manufacturing practices, as products will be printed on demand, reducing waste and excess inventory. Additionally, consumers may increasingly expect personalized products, leading to changes in consumer behavior and new business models focused on customization.

Additive printing is transforming the way products are designed, manufactured, and customized. By offering unparalleled flexibility, precision, and cost-efficiency, it is enabling unprecedented levels of product customization across a wide range of industries. As additive printing technologies continue to evolve, they will play an even greater role in shaping the future of manufacturing and consumer experiences.