How To Choose The Right Size Cable For Control Panels

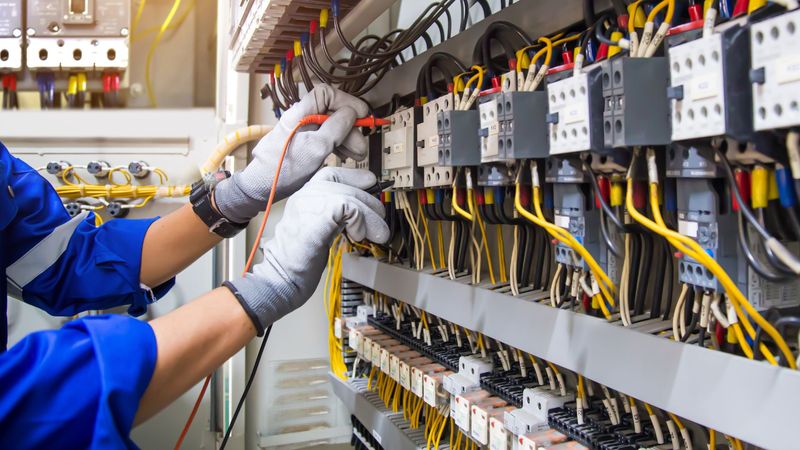

Cables are a vital component of your control panel, as they convey precise operating instructions to the various applications in your automated system. They provide the conduit for constant communication between control devices and sensors.

This article was first published on

www.rowse-automation.co.ukThis ensures the proper functioning of machinery and regulates key industrial processes. To be sure of maximum efficiency and machine safety, it's crucial to determine the right size and type of cable. Specific applications also demand different types of control cables to meet different requirements, including things like security access control cables and throttle control cables.

Key Factors In Sizing Your Cable

There are several key factors to consider when choosing the right size cable for control panels, including:

The required length of the cable

The type of load the cable will carry

The cable's current carrying capacity

The potential voltage drop along the cable's length

The choice of insulation and cable protection

Environmental conditions

Prevailing standards and regulations

The manufacturer's recommendations

In many cases, you can use an online calculation tool to help you choose the cable size that is right for your control panels once you’ve factored in all the variables.

Cable Length

How far the cable has to travel will affect its level of resistance, and this in turn has an effect on the voltage drop. The longer the cable is, the higher will be its resistance, so you might need to choose a cable with a larger cross-section if your cable has a long way to go. This will help reduce the electrical resistance and maintain optimal performance.

Type Of Load

Different types of electrical load require differently sized cables, so you need to determine what type of load is carried by your control system:

Capacitive loads are typically found in certain electronic devices, LED drivers and capacitor banks.

Inductive loads are typically found in motors, solenoids and transformers. They create magnetic fields and, if the current is interrupted, have the ability to generate electromagnetic force.

Resistive loads are typically found in things like heaters and heating elements, plus incandescent lights.

Control panels for automated systems are usually made up of a mix of these load types. Complex automation requires the efficient interaction of communications devices, sensors, actuators and advanced technological devices like variable speed or frequency drives, which all contribute to a complicated electrical load. For this reason, many cables for control panels are likely to be multi-core in order to handle a variety of tasks.

Current Carrying Capacity

You need to know the maximum amount of current you require the cable to carry, to avoid potential fire hazards from overheating. Current ratings are usually specified in amps, so check that your cable has a high enough rating to handle the current safely in the appropriate applications. The larger the cross-section measurement of your cable, the greater will be its current carrying capacity. This capacity is also affected by the number of cores in your cable, so a cable with three or more cores will carry less current than a cable with only two.

Voltage Drop

You need to be sure the voltage drop over the cable’s full length is within acceptable limits. If the voltage drop is too high, you might find the control panel is not performing efficiently and could malfunction. The best way to test for voltage drop is to measure the voltage at different points in the circuit with a multimeter.

Insulation And Cable Protection

To ensure the precise control required in automated systems, electrical control cables need to be resistant to electromagnetic interference and deliver stable transmission. Control cables are, therefore, typically insulated with some form of PVC or polymer construction and may be sheathed or armoured. Some cable sizes offer braided copper wire shielding that helps to minimise interference, while some types of insulation can function in higher temperatures than others. The maximum operating temperature of polyvinyl chloride (PVC), for example, is 70 Degrees, while that of cross-linked polyethylene (XLPE) and ethylene-propylene rubber (EPR) is 90 Degrees.

Environmental Conditions

The control cable’s installation environment will influence its performance. You’ll need to consider what effect factors like humidity, operating temperature and potential exposure to chemicals will have on the cable's operational efficiency and lifespan. Control cables are known to be flexible and reliable in many adverse situations, including the capacity to operate at temperatures up to 80C. The higher the temperature, the larger the cable size will need to be to carry the load safely.

Standards And Regulations

To ensure your safety and official standing, any size and type of cable you select for your control panel must comply with the relevant electrical standards and regulations. The most important of these is the UK standard BS 7671 of the Wiring Regulations, which governs electrical installations.

Manufacturer's Recommendations

The manufacturers of specific types of control panels and cables will usually provide guidelines and recommendations for their use. They may offer detailed specifications, which will help you determine the appropriate size cable for your application.

Why Control Cables Are Important

You’ll find these critical transmission cables in control panels for many instrumentation and automation applications. They’re important for measuring and regulating the signals and energy required to control many different types of automated processes. Control electrical cable is both robust and flexible enough to transmit data and power from the system to any given control point. It provides precise manipulation and control of such industrial applications as CNC machine tools, robots and fully automated processes.

Choosing the right type of cable for your control panel is a priority, whether you’re transmitting electronic signals, controlling industrial machinery, or ensuring that transportation vehicles operate reliably. More importantly, choosing the right size cable for the control panel is a key element in this process, as it plays a major role in ensuring that your applications can be operated safely and with optimum efficiency.