Improving precision folding with 3D printing

As a manufacturer of equipment for laundry services, Girbau sought to improve the efficiency of their folding machines using additive manufacturing.

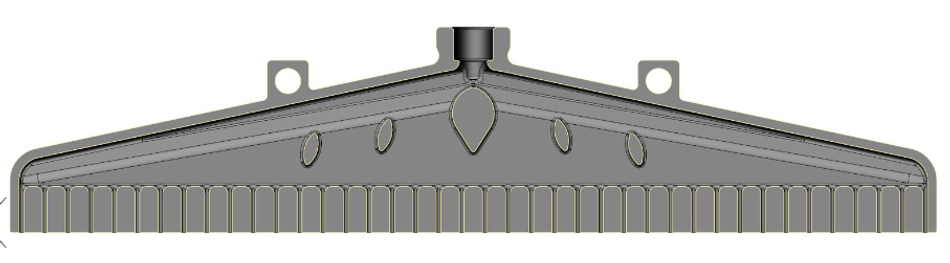

Girbau part printed in EPD 1006 Resin.

Overview

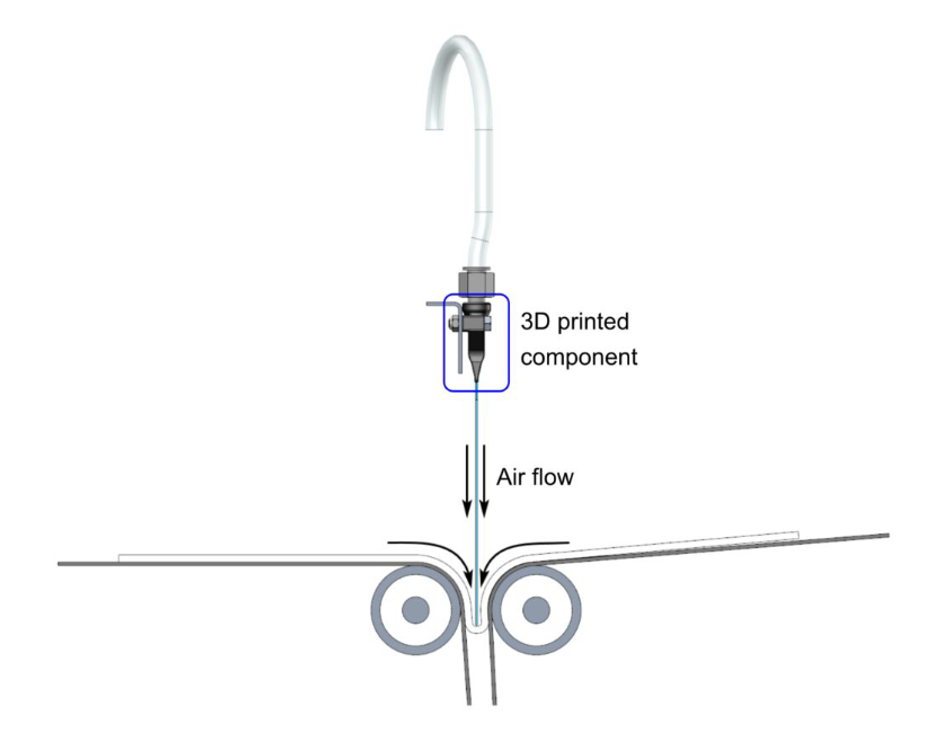

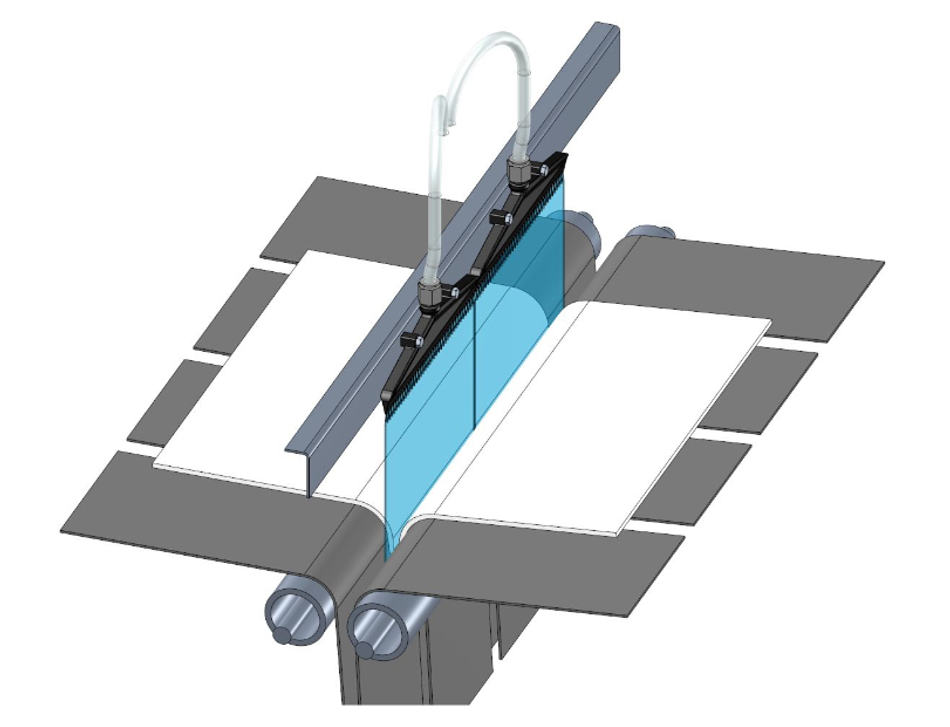

As a manufacturer of equipment for laundry services, Girbau sought to improve the efficiency of their folding machines. In realizing that the air flow of their folding machine was not optimal for the precision folding they needed, Girbau turned to 3D printing for the speed, efficiency, limitless design possibilities, and cost-effectiveness of this technology to create the single solution part they needed to optimize their folding machines.

Challenges

- Redesigning of a part within a folding machine while still maintaining a competitive price point.

- Using a material that is strong enough to create small cavities within the part to withstand high pressure

The Girbau Group is a company that manufactures equipment for laundry services.

With its headquarters in Vic (Barcelona-Spain), it has four production centers: specializing in the manufacture of equipment for small and medium sized laundromats, and for the industrial division, corresponding to laundry service providers with higher production requirements. In addition to distributors worldwide.

Design-Driven Mamufacturing

Optimizing internal geometry for better performances

The small channels created within the part to direct airflow significantly reduced the noise impact the machine makes. Previously with the basic drilled tube part, the airflow did not have a precise direction and the single tunnel echoed the sound of the air pressure.

Making the most of integrated functions

A more compact model that would not be possible to find in the market or challenging to create with traditional manufacturing methods.

Integrated functions Ultracur3D® EPD 1006 : The precision needed to meet manufacturing challenges

Integrated functions Ultracur3D® EPD 1006 : The precision needed to meet manufacturing challenges

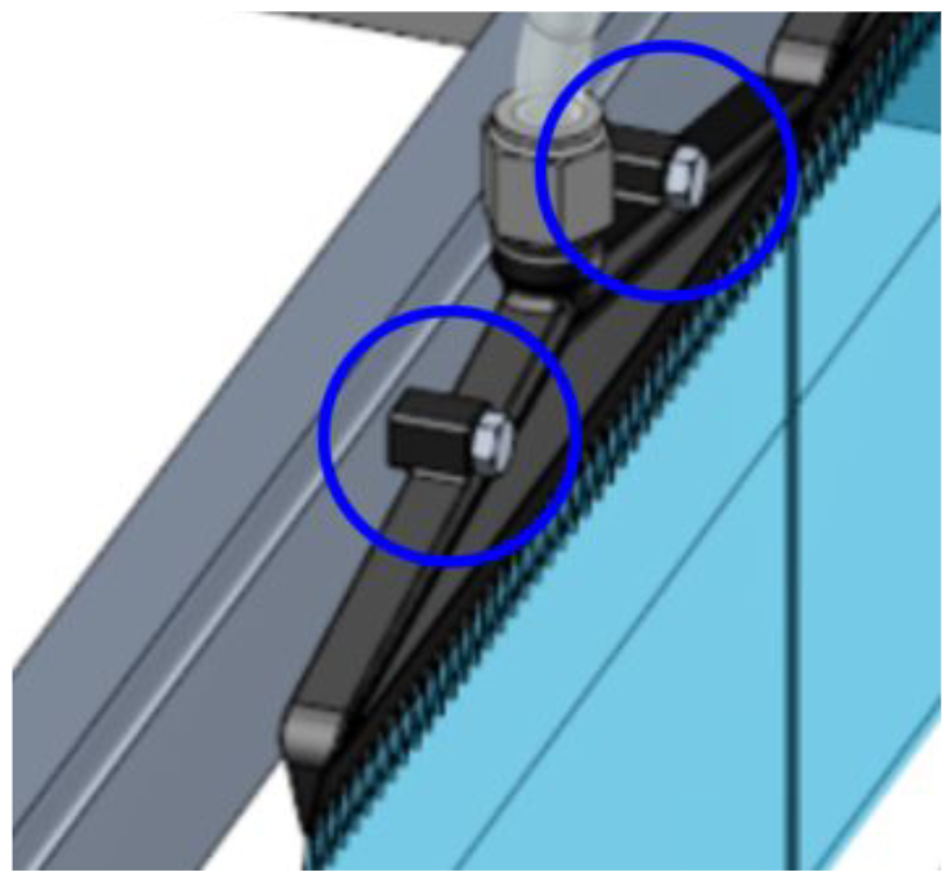

With a final design, Girbau turned to Sculpteo’s online printing service to create a prototype that would potentially be the final part for their machines. They decided on SLS (selective laser sintering) technology and Nylon PA12 material. When testing the part, they realized that there was excess powder from the PA12 material blocking the airflow.

With Sculpteo’s responsive customer support, Girbau was advised to use LCD (Liquid Crystal Display) printing technology to create tiny channels within the part, which powder technology cannot do, using the resin material EPD 1006. Parts printed with resin materials have high accuracy and are perfect for designs that require high precision, like Girbau’s part. Using LCD technology to print their part also allows for higher productivity, thanks to its large printing trays that allow for large series productions.

Following Sculpteo's design guidelines about the specificities of this material, they designed the part so that the inner surfaces are free of any supports, ensuring the optimization of airflow. Sculpteo’s design guidelines helped Girbau ensure that their design would have the highest quality print and functionality possible.

Material Spotlight: EPD 1006

Ultracur3D® EPD 1006 is a resin for 3D printing, developed by Photocentric technology and belonging to the photopolymer materials Engineering Plastic Daylight (EPD) line. This is a photosensitive resin.

This resin is suitable for many applications and is particularly useful for manufacturing large parts, with a platform measuring 510 mm x 280 mm. The Ultracur3D® EPD 1006 offers the ability to create high-quality components for demanding applications and industries at a competitive price.