Is 3D Printing Used In Mass Manufacturing?

3D printing hasn’t been viable up to now as a technology for mass production. It’s still in the early stages of development and different processes are still being formulated.

This article was first published on

www.rowse.co.ukLaser techniques are also available, including selective laser sintering (SLS) and modelling (SLM). However, newer and more sophisticated processes like digital light printing or synthesis (DLP/DLS) may be set to change the outlook for mass production.

Additive Manufacturing

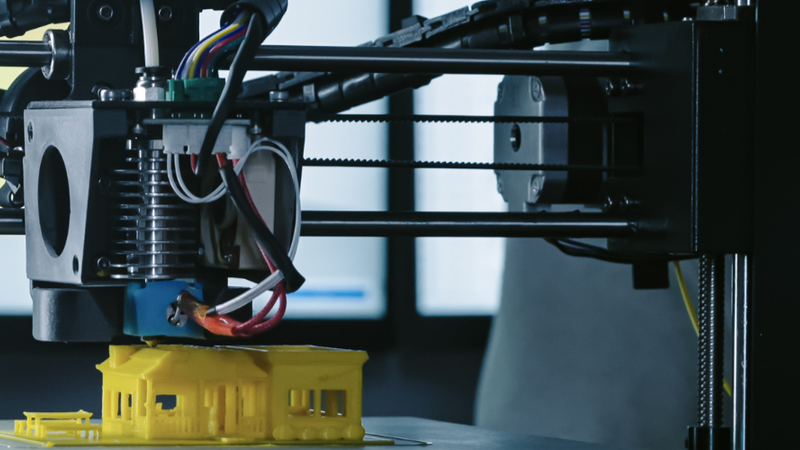

Originally known as additive manufacturing, 3D printing is a process of creating products by building up a 3D object. It’s based on computer-aided design (CAD), and exploits a variety of different materials and novel technologies. Materials can include anything from natural fibres and metals to chemicals and advanced plastic polymers. The developing technologies are being assisted in some instances by artificial intelligence (AI).

The latest advances are in the field of laser printing, where DLP/DLS is proving very innovative in producing objects in the biomedical field, such as sterilisable, organic parts like replacement organs. It’s even possible to use thermoset resins with DLP technologies to print foam structures, for products in the sporting goods, footwear, furnishing and automotive industries. With no tooling required, you can print closed-cell foam parts in much more complex designs, that will not only perform better but also reduce waste.

RAPID PROTOTYPING CAN ACCELERATE PRODUCTION

During the early design stages of creating new products, it’s critical to have functional prototypes so you can see whether various aspects are going to work or not. Previously, you would have had to outsource the production of prototypes, which could be very time-consuming. If you adopt 3D printing methods instead, you can produce prototypes in-house. With 3D-printed rapid prototyping, you can create physical models very quickly to inspect for design flaws and functionality, then incorporate changes in repeated iterations until you get it right. All this is much faster and more cost-effective than the traditional method.

HYBRIDISATION

Another way in which additive manufacturing is speeding up the production process is with hybridisation. This means that you still use traditional manufacturing methods, but deploy 3D printers to create the necessary setup. For example, you can print the required moulds for injection moulding techniques, or finish precision parts with CNC machining.

The most innovative new techniques – especially DLP/S – are capable of producing vast quantities of high-quality, end-user items. A good example of this is the printing of soles for training shoes, where one company’s patented tech has contributed to producing more than 100,000 pairs of trainers in a single year.

ADAPTABILITY

Additive manufacturing is extremely customisable, with a constantly expanding range of materials and techniques. You might want to print the same item in different materials, to determine which demonstrates the better functionality or cost-effectiveness, or create hybrids with more than one material. It’s also extremely adaptable and is being tested for its compatibility with new technologies.

You might combine it with digital twinning to reproduce obsolete parts or use it to manufacture novel components like art objects or mathematical models. You might create and combine 3D printed products with smart Industry 4.0 equipment. For example, you can integrate 3D printing software with AI to improve print calibration and fine-tune slicer settings.

Advantages Of 3D Printing In High-Volume Production

Once you have tested and finalised a working prototype, you can ramp up your manufacturing volume in various ways. Speeding up your tooling processes with printed moulds or casts gives you greater production flexibility. Individual or brand customisation also contributes to your flexibility and increases the affordability of products for customers. Things like printing custom soles for a given brand of trainers mean you can achieve higher volumes and get your product more quickly to market.

HIGH-SPEED MANUFACTURING PROCESSES

Because it’s all digital, 3D printing technology can print products with extremely complex shapes and geometries. DLP/S, for instance, uses the properties of UV light and oxygen operating on photopolymer resins to print organic and biocompatible parts. In the DLS process patented by one market-leading company, UV images of an object are cast through an oxygen-permeable window into a photopolymer reservoir, where the layers are gradually built up, then cured in ovens to produce printed parts.

DESIGN FLEXIBILITY

DLP processes enable you to create production-ready parts within days rather than weeks. You can use a wide range of rigid or elastomeric thermoset materials such as plastics, resins and composites. These achieve extraordinary resolution, mechanical properties and surface finish. Instead of needing to produce and combine several components for a particular part, you can consolidate them into one printed item, which also speeds up production.

ON-DEMAND PRODUCTION

Although additive manufacturing processes offer great advantages for prototyping unusual or custom parts, the latest developments in DLP are much better suited for volume repeat production. Digital products have endless iteration potential, combined with AI-driven controls to ensure quality. Once any design is finalised, you can use it to create a digital inventory. This will allow you to switch to on-demand production and reduce your time to market.

Mass Production For Your 3D Printing Budget

3D printing requires an initial investment in hardware, software and materials. Once you’ve assessed which printing technologies best suit your needs, chosen your materials and adapted any necessary processes, you can streamline the manufacturing process to achieve better and faster results. Manufacturers who have already upgraded to automated systems and networked services will be able to achieve savings and scalability when higher volume production runs are established.

The 3D printing horizon is constantly advancing and we’re beginning to see new potential for high-volume manufacturing. More and different techniques are being developed, allowing business owners to choose from a myriad of options that might open the door to mass production. At this stage of technological development, you might want to subscribe to a leasing programme while you figure out what works best for you.