Is PLA Biodegradable? What To Do With Scrap Filament

As one of the few thermoplastic 3D printing materials derived from natural sources, PLA is often assumed to be the most eco-friendly. But is that true?

Polylactic acid (PLA), a versatile bioplastic derived from renewable resources, tends to be seen as the greenest of common thermoplastic 3D printing materials. It is marketed as a relatively safe, non-toxic material that is biodegradable after use.

Indeed, this plant-based polymer offers a potential alternative to conventional petroleum-based plastics, addressing the critical need for biodegradable materials in various engineering applications. The importance of such materials extends beyond mere waste reduction; they play a crucial role in promoting circular economy principles and mitigating the environmental impact of plastic pollution. However, as environmental concerns over all forms of manufacturing have intensified, the biodegradability of PLA has become a point of discussion for engineers and researchers alike.

In simple terms, used PLA filament cannot simply be thrown into your garden compost heap, but it is biodegradable under specific conditions. This article looks at the science behind biodegrading PLA, as well as practical considerations for discarding scrap 3D printer filament.

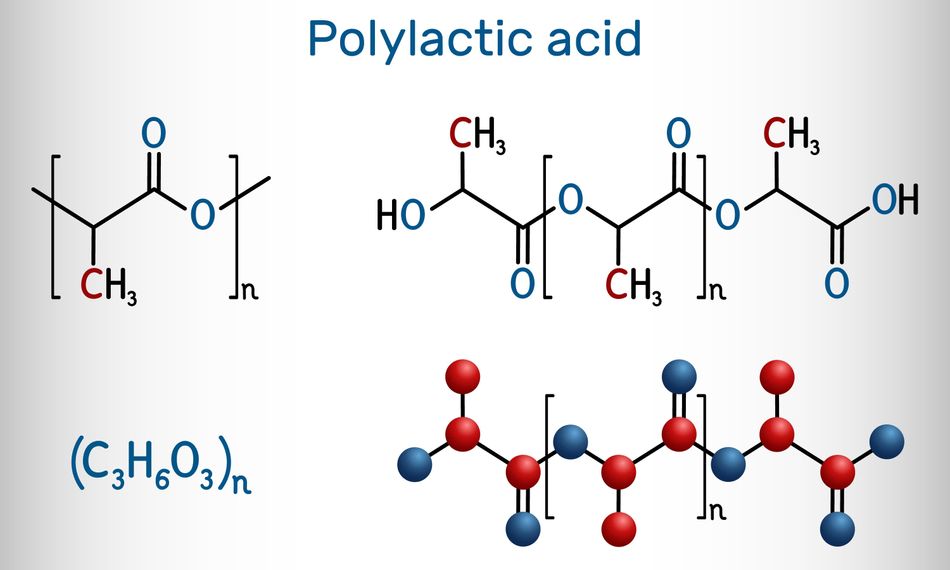

The Molecular Makeup of PLA: A Closer Look

Polylactic acid (PLA) is a biopolymer with a unique molecular structure that sets it apart from traditional petroleum-based plastics. Its backbone formula is (C3H4O2)n. At its core, PLA is composed of lactic acid monomers, which are derived from renewable plant sources such as corn starch or sugarcane.[1] These lactic acid molecules undergo a polymerization process to form the long chains of PLA.

Unlike petroleum-based plastics, which are derived from non-renewable fossil fuels, PLA's plant-based origins contribute to its sustainability profile. The production of PLA typically involves fermenting plant starches to produce lactic acid, which is then polymerized through various methods, such as direct condensation or ring-opening polymerization of lactide.[2]

Key properties of PLA relevant to its biodegradability include:

Presence of hydrolyzable ester bonds

Higher hydrophilicity compared to conventional plastics

Susceptibility to enzymatic degradation

Stereocomplex formation capability (between L- and D-lactide units)

These properties contribute to PLA's ability to break down under specific environmental conditions, making it an attractive option for biodegradable applications in various engineering fields.

PLA Biodegradability vs. Other Filaments

The molecular structure of Polylactic acid (PLA) differs significantly from petroleum-based 3D printing plastic like ABS and PETG, which directly influences its biodegradability potential.

ABS is a terpolymer consisting of three monomers: acrylonitrile, butadiene, and styrene. The acrylonitrile provides chemical resistance, butadiene adds toughness, and styrene gives rigidity and processability. ABS has a complex structure, with strong intermolecular forces and cross-linked chains that resist environmental degradation. The butadiene component especially contributes to ABS's durability and its resistance to microbial attack. This results in ABS being highly resistant to biodegradation, often persisting for centuries in landfills.

PETG is a glycol-modified version of PET, with ethylene glycol incorporated into the polymer chain to improve flexibility. The polymer consists of repeating terephthalate units, and the addition of glycol inhibits crystallization, making PETG more amorphous and easier to process. PETG’s structure, like ABS, is resistant to biodegradation due to its strong ester bonds and aromatic rings, which are stable in most environmental conditions. This makes PETG durable but not biodegradable. On the other hand, both ABS and PETG can be recycled in many locations.

Recommended reading: PLA vs ABS: Which Filament Should One Use?

PLA Biodegradability: Fact or Fiction?

Biodegradability, in the context of plastics and polymers, refers to the material's ability to break down into natural substances such as water, carbon dioxide, and biomass through the action of naturally occurring microorganisms. For Polylactic acid (PLA), this process is not just theoretical but a demonstrable reality under specific conditions.

PLA biodegradation occurs through two primary mechanisms: hydrolysis and microbial action. Hydrolysis, the initial step, involves the breaking of ester bonds in the PLA polymer chain by water molecules. This process reduces the molecular weight of PLA, making it more susceptible to microbial attack. Subsequently, microorganisms present in the environment can metabolize these smaller PLA fragments, converting them into biomass, CO2, and water.[3]

The biodegradation of PLA is heavily dependent on environmental conditions. Optimal PLA biodegradation typically requires:

Temperatures above 58°C (136°F)

Relative humidity above 70%

Presence of specific microorganisms capable of metabolizing PLA

pH levels between 5.5 and 8.0

Adequate oxygen levels for aerobic biodegradation

These conditions are commonly found in industrial composting facilities but are unlikely to occur in home composting setups or natural environments, which explains why PLA may not biodegrade readily in all situations. In fact, in many everyday disposal scenarios, PLA may not biodegrade any faster than conventional plastics, underscoring the importance of proper waste management and disposal practices for this material.

The stages of PLA biodegradation can be outlined as follows:

Moisture absorption: PLA begins to absorb water from its environment.

Hydrolysis initiation: Water molecules start breaking the ester bonds in PLA.

Molecular weight reduction: The polymer chains break into smaller fragments.

Microbial colonization: Microorganisms begin to colonize the PLA surface.

Enzymatic degradation: Microbes secrete enzymes that further break down PLA.

Assimilation: Microorganisms consume the small PLA fragments.

Biomass and gas production: The consumed PLA is converted into biomass, CO2, and water.

How Long Does PLA Take to Biodegrade?

The biodegradation rate of Polylactic acid (PLA) varies depending on environmental conditions. Under optimal industrial composting conditions, PLA can biodegrade to a significant reduction in mass in around 30 to 60 days. However, in less ideal environments, the process can take much longer. In landfill or cold home composting setups, PLA often degrades no faster than plastics derived from fossil fuels. Biodegradation times are heavily influenced by temperature, humidity, microbial activity, pH levels, and aerobic conditions.

What Should You Do With Scrap PLA Filament?

Since PLA is a bio-based and biodegradable polymer, one might assume that the material is suitable for home composting, but this is generally not the case due to the high temperatures required for biodegradation. However, the compostable plastic can be sent to an industrial composting facility.

Depending on where you live, you may be able to put PLA scraps in with other organic waste to be collected by a municipal waste organization. Generally, it depends on whether organic waste in the area goes through a Biomethanization process prior to composting or not. PLA is not suitable for this process, so areas that send organic waste for Biomethanization will not accept PLA. If this is the case for your area, you can try to find a commercial or industrial composting location independently.

If composting is not a feasible option, recycling PLA is another route. Scrap PLA cannot generally be mixed into regular plastic recycling streams, but can be sent to special facilities for recycling. Incineration is another option. Putting scrap PLA with general waste for landfill should be a last resort, as the plastic will degrade extremely slowly in those conditions.

Recommended reading: PLA Recycling: Can PLA 3D Printer Filament be Recycled?

PLA's Environmental Footprint: Beyond Biodegradability

Polylactic acid (PLA) is often touted as an environmentally friendly alternative to traditional plastics due to its biodegradability. However, a comprehensive analysis of its environmental footprint requires examining its entire life cycle, from production to disposal. The life cycle of PLA begins with the cultivation of raw materials, typically corn or sugarcane. These crops undergo fermentation to produce lactic acid, which is then polymerized into PLA. The polymer is processed into various products, used by consumers, and finally disposed of or recycled.

Compared to traditional plastics, PLA generally has a lower environmental impact. Its production requires less fossil fuel and generates fewer greenhouse gas emissions. However, the exact environmental benefits can vary depending on the specific production processes and energy sources used.

While PLA production emits less CO2 than traditional plastic production, it is not carbon-neutral. The fermentation process and energy used in manufacturing contribute to greenhouse gas emissions. However, the plants used as raw materials absorb CO2 during growth, partially offsetting these emissions. The net climate impact depends on factors such as agricultural practices, processing efficiency, and end-of-life management.

Land use for PLA raw material production is a significant concern. The cultivation of corn or sugarcane for PLA competes with food production and can lead to land-use changes. This competition could potentially impact food security and biodiversity. However, research is ongoing into using agricultural waste or non-food crops as PLA feedstocks, which could mitigate these concerns.

Conclusion

Polylactic acid (PLA) represents a significant advancement in biodegradable materials, offering a potential solution to the persistent problem of plastic pollution. Its ability to break down under specific conditions, particularly in industrial composting facilities, sets it apart from traditional plastics. Proper disposal and composting practices are crucial for realizing the full environmental benefits of PLA. Without appropriate end-of-life management, PLA may not biodegrade efficiently, potentially contributing to waste accumulation.

Frequently Asked Questions

Q: How long does it take for PLA to biodegrade in a home compost bin?

A: PLA biodegradation in (cold) home compost bins is ineffective, with the plastic taking potentially hundreds of years to degrade at ambient temperatures. Industrial (hot) composting facilities are required to compost PLA effectively.

Q: Can PLA be recycled with other plastics?

A: PLA should not be mixed with other plastics for recycling. It requires specific recycling processes different from those used for conventional plastics. Mixing PLA with other plastics can contaminate the recycling stream.

Q: How does the strength of PLA compare to traditional plastics?

A: PLA's strength can be comparable to some traditional plastics like polystyrene, but it's generally less durable than other common filaments like ABS. Its mechanical properties can be enhanced through various techniques such as blending with other polymers or adding reinforcing fibers.

Q: Is PLA production more energy-efficient than traditional plastic production?

A: PLA production typically requires less energy than the production of petroleum-based plastics, though exact figures depend on specific production methods and energy sources.

References

[1] Fatchurrohman N, Muhida R. From Corn to Cassava: Unveiling PLA Origins for Sustainable 3D Printing. Jurnal Teknologi. 2023 Dec 31;13(2):87-93.

[2] Hu Y, Daoud WA, Cheuk KK, Lin CS. Newly developed techniques on polycondensation, ring-opening polymerization and polymer modification: Focus on poly (lactic acid). Materials. 2016 Feb 26;9(3):133.

[3] Elsawy MA, Kim KH, Park JW, Deep A. Hydrolytic degradation of polylactic acid (PLA) and its composites. Renewable and Sustainable Energy Reviews. 2017 Nov 1;79:1346-52.