Is UV Resin Toxic? Risks and Safety Measures Explained

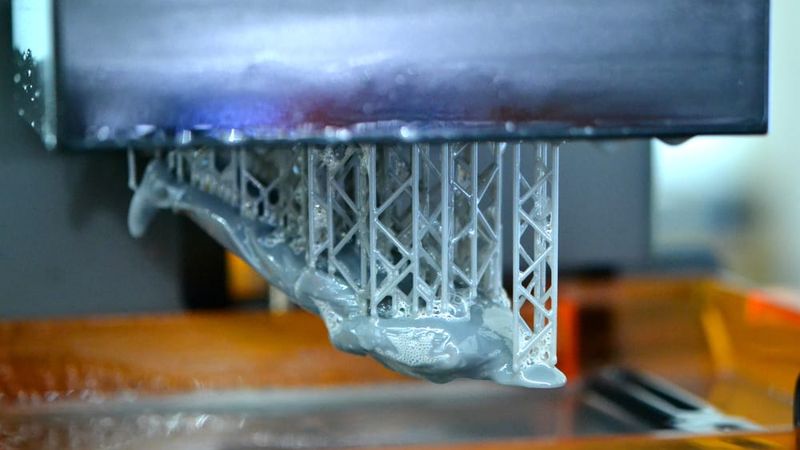

Resin 3D printing technologies like SLA and DLP offer excellent resolution and surface quality compared to FDM. But is UV resin toxic in its liquid or cured form, and, if so, how can you print it safely?

Is UV resin toxic? Yes, especially in its uncured liquid state

Vat photopolymerization 3D printing technologies that use liquid resin as a base material offer numerous advantages. Laser-based processes like stereolithography (SLA) provide incredible resolution and are perfect for highly detailed models or jewelry casting, while processes that use other light sources like digital light processing (DLP) and masked SLA (mSLA) are lightning-fast — they can actually print entire layers of a part at once — and are therefore great for rapid prototyping.

That being said, newcomers to resin 3D printers might be unfamiliar with the liquid 3D printer resins used for the process and the safety considerations required to handle them. Liquid resins have virtually nothing in common with fused deposition modeling (FDM/FFF) materials like PLA, which are packaged as spools of solid filament, and they require proper care when loaded into a resin 3D printer.

One of the most important questions asked by resin 3D printing beginners is, “Is UV resin toxic?” The short answer is yes, they are, but there are many factors to consider when getting to grips with these printing materials. This article attempts to answer the question, "Is UV resin toxic?" while looking at the basics of UV resin safety. It considers the toxicity of both liquid and cured resin and the steps required to protect oneself and the environment when deploying resin 3D printing processes.

What is Resin 3D Printing?

Technology | Light source | Advantages |

Stereolithography (SLA) | Laser | Best print accuracy |

Digital Light Processing (DLP) | DLP projector | Faster printing |

Masked SLA (mSLA) or Liquid Crystal Display (LCD) | LEDs shone through LCD | Lowest cost |

Resin 3D printing technologies, sometimes called vat photopolymerization technologies, are a group of photochemical additive manufacturing processes that use resins as a printing material.

Resin 3D printers contain a tank of liquid resin (a kind of thermosetting photopolymer) and use a light source such as a laser (SLA) or a projector (DLP) to shine patterns of bright ultraviolet (UV) light onto the tank. When the light hits the liquid resin, it cures a thin layer of the material, turning it solid. This allows the resin printer to selectively cure a 2D pattern into a layer of the resin, then move its tank or light source incrementally to allow curing of the next layer.

The resin printing process offers numerous advantages, such as high resolution and a smooth, step-free surface. SLA is best for high-quality detailed parts, while DLP and mSLA/LCD can be very fast, as the projector or LCD screen can cure a whole 2D layer with one flash of UV light. Resin printed parts are brittle and not particularly strong, but they are ideal for visual parts such as display prototypes. Resin printing is also one of the best ways to make transparent or translucent parts.

Although FDM 3D printing is now more common than SLA, DLP, or mSLA, resin 3D printing was actually the first form of 3D printing, patented in the 1980s by 3D Systems co-founder Chuck Hull. Formerly an expensive process reserved for professional users, resin printing is now widespread, with machines available at low prices from consumer stores like Amazon.

Recommended reading: Resin vs. Filament 3D Printer: Pros and Cons of Curing and Extrusion

Yes, UV Resin is Toxic

Without further ado, it is important to disclose at the outset that yes, UV resin is a toxic substance that requires strict safety precautions. In its uncured liquid form, UV resin contains irritants that can be harmful to humans, as well as pollutants that can be harmful to the environment and other living species.

Some of the potential harmful effects of resin are suspected but not confirmed due to lack of research. Long-term risks may include menstrual problems, altered sexual behavior or fertility, and damage to unborn children during pregnancy. A 2016 study found that SLA printed parts were far more harmful to zebrafish embryos than FDM parts:

Zebrafish embryos were exposed to 3D-printed parts and monitored for rates of survival, hatching, and developmental abnormalities. We found that parts from both types of printers were measurably toxic to zebrafish embryos, with [Sterolithography]-printed parts significantly more toxic than FDM-printed parts.[1]

The chemical properties of liquid photopolymers make them poisonous if ingested and also a potential skin irritant and allergen. Furthermore, uncured resin is classified as hazardous to aquatic life. So why and how exactly is UV resin toxic?

Skin irritant

Uncured liquid resin can irritate bare skin and can cause a rash called contact dermatitis. This can ultimately become more severe and cause an allergic reaction after prolonged skin contact. Several ingredients in common 3D printing resins can cause skin irritation. These include isooctyl acrylate, HDODA, HEMA, and epoxidized soybean oil.[2]

Eye irritant

Several ingredients in consumer 3D printing resins (including pre-polymers, photoinitiators, and plasticizers) can be harmful to human eyes.

Poisonous if ingested

Resin should never be ingested in either its liquid or solid form. If 3D printing resin is accidentally swallowed, urgently seek assistance from poison control or a medical professional. Some photoinitiators in common 3D printing resins have a significant level of organ toxicity.

As with most FDM materials, resins are not food-safe even in their cured state, so processes like SLA and DLP should not be used to directly fabricate products like food containers, cookie cutters, or drinking vessels. However, to leverage the advantages of resin 3D printing for food parts, it is possible to make 3D printed resin casting molds or patterns which can then be used to make parts from genuinely food-safe materials. Note that these moldings should be thoroughly washed before use, as they will have been in contact with the resin mold.

Dangerous fumes

Liquid 3D printing resins give off fumes or vapors containing volatile organic compounds (VOCs) that can be harmful to humans if inhaled into the throat or lungs. Short-term exposure to resin fumes can result in dizziness, headaches, and throat irritation. The long-term risks are unknown due to lack of research, but may include increased risk of cancer.

Environmentally harmful

3D printing resins are harmful to the environment and should be classified as toxic waste. This means they should never be poured down the drain or directly into bodies of water, but should instead be safely bottled up and disposed of through dedicated toxic waste channels. Photopolymer resins are a pollutant that can kill marine life and destroy ecosystems.

Fully cured UV resin is less environmentally harmful than liquid resin and is therefore easier to dispose of. Alternatively, it is possible to use bio-based resins that are much less harmful to the environment, even in their liquid form.

How to Safely Use Resins

Although liquid 3D printing resins are toxic, potentially irritating skin and giving off harmful fumes, they are safe to use if the appropriate safety precautions are taken. Such precautions include the use of personal protective equipment like safety glasses and nitrile gloves, as well as proper disposal containers.

Prepare the work area

Since liquid resins give off fumes that can harm the throat and lungs if inhaled, it is imperative to use resin 3D printers in a properly ventilated area.

The best solution when dealing with resin fumes is to have a ventilation hood over the work area to ensure that the harmful fumes are removed from the room as efficiently as possible. In environments where this setup is not possible — at home, for instance — then the work area should at least be positioned close to an open window.

The ideal ventilated environment for resin 3D printing should provide:

- An air exchange rate of at least 10 air changes per hour in the area where UV resin is being used

- A local exhaust ventilation system with a minimum capture velocity of 100 feet per minute

- High-efficiency particulate air (HEPA) filters with a minimum efficiency of 99.97% for particles 0.3 microns in size

Resin printer users should also use a non-porous workspace such as a glass table or a surface covered with a plastic sheet. This will prevent the harmful resin seeping into, for example, wooden surfaces.

Familiarize yourself with the safety data sheet

All manufacturers of liquid resins for 3D printing must provide a safety data sheet (SDS) for each material. These documents provide information about the material’s ingredients (though sometimes to a limited extent due to trade secrets), its toxicity levels, and the appropriate safety measures that should be taken when working with the product.

Wear gloves

When handling toxic UV resins, it is imperative to wear protective nitrile or neoprene gloves, preventing potential skin irritation if small spillages occur. Though not as flexible, nitrile rubber offers superior chemical resistance to other forms of rubber.

Wear protective eyewear

Safety glasses or goggles with side shields should be used when handling UV resins, since these materials contain several ingredients that can be harmful to eyes.

Wear a respirator

In addition to creating a well-ventilated work area, operators of UV resin printers should wear a respirator — a half-face respirator with organic vapor cartridges and a P100 filter, for example — to avoid inhaling fumes from the uncured resin. A suitable type of respirator is the 3M 60921, which is cheap and lasts several months.

Cure unused resin if possible

As we will discuss in the following section, there are ways to safely dispose of uncured liquid resin. However, it is much easier and safer to dispose of hardened, fully cured resin, which is much less toxic and therefore less harmful to humans and the environment.

The unused resin does not have to go through the 3D printer to be cured. Instead, it can be left in a clear container in direct sunlight. The UV rays from the sun can carry out the resin curing process instead of the printer’s light source, and the container of hardened resin can then be disposed of as solid waste. Paper towels soiled with liquid resin should also be left in the sun (in a ventilated area) and left to harden before disposal. If curing is not possible, resins and contaminated items like gloves should be considered hazardous waste.

Protecting the Environment when Using Resins

Users of resin 3D printing equipment should consider the environmental impact of the printing process, disposing of resins safely in a way that does not pose a risk to aquatic life. Additionally, some material manufacturers offer bio-based resins that are much less harmful to the environment than ordinary synthetic resins.

Toxic waste disposal

Because uncured liquid 3D printing resins can kill marine animals, they cannot be poured down the sink, flushed down the toilet, or thrown out with regular garbage. Disposal of UV resins can be via a chemical waste stream (uncured liquid resin) or without (cured resin).

Via chemical waste streams

Uncured liquid resin can only be disposed of via a proper chemical waste stream organized by the local authority, typically by storing the material in a sealed container and delivering it to a waste management facility.

In the US, hazardous waste disposal is managed by the EPA, the United States Environmental Protection Agency. In Europe, the European Commission oversees application of the Waste Framework Directive.

Without chemical waste streams

Disposing of UV resin without a regulated chemical waste stream requires curing of the resin until it is fully solidified. This involves pouring a small amount of liquid resin into a clear container, then leaving it in direct sunlight for up to 10 days until it is fully solidified. Handling the uncured resin requires the same safety procedures (gloves, eyewear, respirator) as when using a 3D printer. Resin-soiled paper towels should also be left in sunlight to cure.

Once the resin is cured, the hardened mass (and any paper towels) can be disposed of with regular household waste.

Bio-based resins

Bio-based resins are derived from natural sources such as lignin, fatty acids, and camphor, and are not harmful to the environment like ordinary resins. Researchers have shown that bio-based resins can provide performance equivalent to ordinary epoxy resins during the SLA process.[3]

Currently available bio-based 3D printing resins include:

eSun eResin-PLA: SLA resin made using PLA monomers (derived from corn starch, sugar cane, or other crop)

Elegoo Plant-based Photopolymer Resin: Rapid-curing resin made largely from soybean, suitable for DLP printing

AnyCubic Plant-based UV Eco-Resin: UV resin made from soybean oil

3Dresyns 3Dresyn Bio D: SLA resin containing bio catalysts and photo oxidative catalysts to speed up biodegradation

Conclusion

Is UV resin toxic? Yes, the liquid resins used in 3D printing processes like SLA and DLP are highly toxic and should be handled with due care: users should wear protective gloves, eyewear, and a respirator to minimize skin and eye contact and the possibility of ingestion, while ensuring that their work area is well-ventilated during printing and material handling.

Users must also consider the environment when using UV resins. Waste liquid resin should be disposed of via the proper channels — it should either be cured and hardened before disposal or sent to a chemical disposal facility — to avoid potential harm to marine wildlife. Bio-based resins are much less harmful to humans and the environment, but are not always 100% bio-based so should still be handled with care.

If all these precautions are followed, resin 3D printing can be a highly valuable prototyping and production process capable of creating smooth, detailed parts such as intricate models, jewelry patterns, dental devices, and much more.

Frequently Asked Questions (FAQ)

What are the main health risks associated with UV resin exposure?

The main health risks associated with UV resin exposure include skin irritation, allergies, respiratory issues, eye irritation, and ingestion hazards. Skin contact with UV resin can cause allergic contact dermatitis, while inhalation of UV resin fumes can lead to respiratory irritation and an increased risk of occupational asthma. Eye contact and accidental ingestion can also cause irritation and damage to the eyes and digestive tract, respectively.

How can I protect myself when working with UV resin?

To protect yourself when working with UV resin, use appropriate personal protective equipment (PPE), such as nitrile or neoprene gloves, safety glasses with side shields, and a half-face respirator with organic vapor cartridges and a P100 filter. Ensure adequate ventilation in the work area, with an air exchange rate of at least 10 air changes per hour. Follow proper storage and disposal protocols, keeping UV resin containers tightly sealed and disposing of waste materials through a licensed hazardous waste management company.

Can I develop an allergy to UV resin over time?

Yes, it is possible to develop an allergy to UV resin over time, even if you have not experienced any allergic reactions previously. Repeated exposure to UV resin and its components, such as acrylate monomers and photoinitiators, can lead to sensitization and the development of allergic contact dermatitis. If you notice any symptoms of skin irritation or allergy, such as redness, itching, or rash, it is important to seek medical attention and take steps to minimize further exposure.

Are there any long-term health effects associated with UV resin exposure?

While the long-term health effects of UV resin exposure are not fully understood, some studies suggest that prolonged exposure may increase the risk of certain health problems. For example, chronic inhalation of UV resin fumes has been associated with an increased risk of occupational asthma and other respiratory disorders.

How should I dispose of unused UV resin and contaminated materials?

Do not pour liquid UV resin down the drain or dispose of it in regular trash, as this can lead to environmental contamination and potential health hazards. Collect unused UV resin and contaminated materials in a transparent container, cure them fully in direct sunlight, and dispose of them in the trash or through a licensed hazardous waste management company.

References

[1] Oskui SM, Diamante G, Liao C, Shi W, Gan J, Schlenk D, Grover WH. Assessing and reducing the toxicity of 3D-printed parts. Environmental Science & Technology Letters. 2016 Jan 12;3(1):1-6.

[2] Resin 3D Printing FAQ [Internet]. 4D Filtration; 2022 [cited 2022 Jun 15].

[3] Voet VS, Strating T, Schnelting GH, Dijkstra P, Tietema M, Xu J, Woortman AJ, Loos K, Jager J, Folkersma R. Biobased acrylate photocurable resin formulation for stereolithography 3D printing. ACS omega. 2018 Feb 2;3(2):1403-8.