Krones: Optimized 3D-printed parts & spares for customers anywhere

To help customers get even more uptime, develop parts faster or create emergency spare parts, Krones turned to 3D printing. With the use of UltiMaker 3D printers, prototypes were able to be produced in a day, or even in hours in some cases.

Printing parts on-demand have shown to reduce costs and improve operational efficiency.

This article was first published on

ultimaker.comEvery day, millions of glass bottles, cans and PET containers run through a Krones line. Krones is a leading manufacturer of complete systems for breweries, beverage bottlers and food producers. Its production lines fill packages, add labels, and perform quality control on the products. As a global market player in the beverage and packaging industry, Krones provides comprehensive solutions that customers, such as Coca-Cola and Heineken, rely on heavily.

When every second counts

The production lines of Krones are extremely efficient in producing, filling, and packing products. But with these massive production volumes, every second counts. When a machine is not running, companies could lose out on significant revenue. This is why it’s critical to have the highest possible uptime. While Krones machines are extremely reliable, every part will wear and might need replacing for optimal performance. While most customers keep a selection of spare parts, it’s unrealistic, expensive and unsustainable to keep a large stock of spares as many of these parts will never be used. Every part needs to be produced, checked and shipped.

3D printing at Krones

To help customers get even more uptime, develop parts faster or create emergency spare parts, Krones turned to 3D printing. Outsourcing the production of prototypes is very expensive and often could take weeks. With the use of UltiMaker 3D printers, prototypes were able to be produced in a day, or even in hours in some cases. By prototyping faster, Krones tested and iterated on their designs faster, ensuring that new parts performed better and lasted longer. This has helped customers with more reliable machines, higher uptime and a smaller environmental footprint.

Benefits of 3D-printed parts over traditional parts

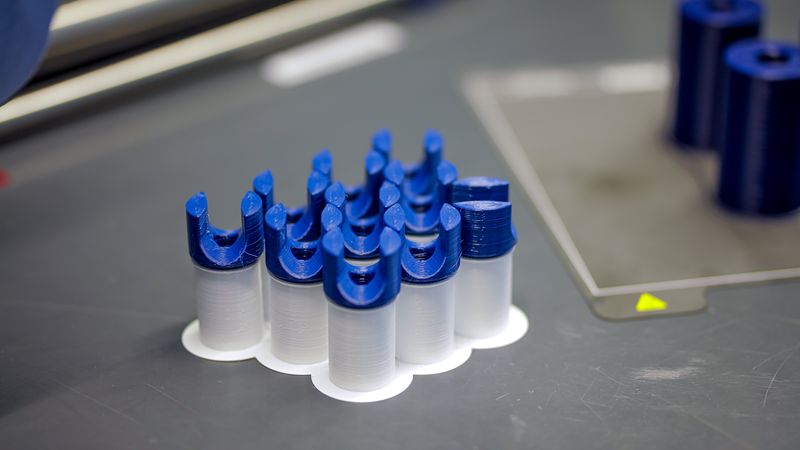

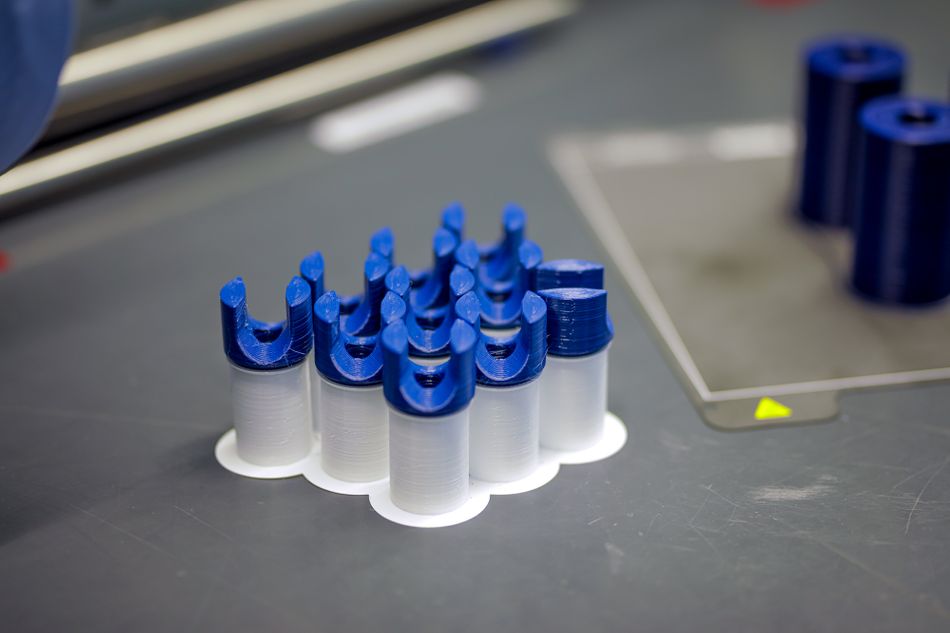

By testing prototypes of parts, Krones discovered that 3D-printed parts met the performance requirements of many final parts. Not only are 3D-printed parts cheaper to produce, their reduced weight is also often a big benefit. Parts can also be printed in different materials depending on the need for different properties, such as more flexibility or ESD-safety. This enabled Krones to shift 3D printing from simply an internal tool to a new revenue stream as an added service for customers.

On-demand production parts for customers, anywhere

When storing a huge stock of spare parts is not desirable or spare parts are needed urgently, you need to be able to acquire parts fast once they are needed. Ordering and shipping parts can take days to weeks, while local stocks or customs can make certain locations difficult to guarantee certain quality service. 3D printing on location offered a huge opportunity for Krones and its customers.

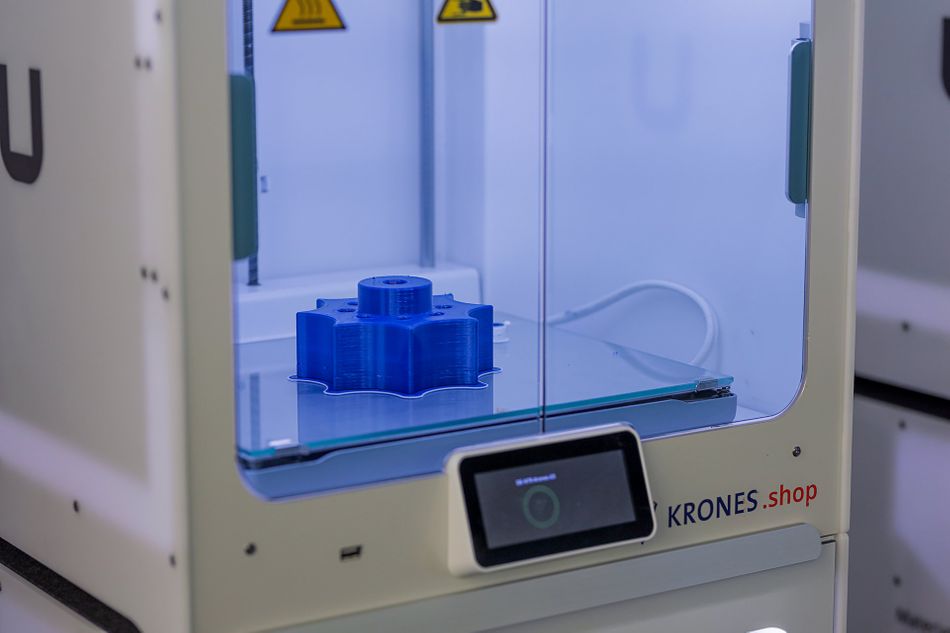

When customers need a spare part for a machine, they can order the part in the Krones.shop - the online customer touchpoint. If the spare part is able to be 3D-printed, it will be produced locally on UltiMaker printers. This way, customers won’t need to store huge quantities of spare parts in all of their locations. They can simply print the parts they need, while minimizing downtime of their production lines drastically. This process reduces part delivery from weeks to days, or even hours.

Quality assurance of 3D printed parts

The functionality and durability of a part depends on many factors. While the design of a part might be the same, the choice of materials and production settings have a great influence on the performance. Krones defines the right materials and print settings for every part. When a customer orders a replacement part for their Krones line, the spare will be 3D printed using customized settings and Krones-specific materials. This results in a certified part that is sure to meet the quality standards required. Krones quality can only be found where it says Krones Quality on the label.

A flexible 3D printing solution that meets strict quality and IT standards

Choosing the right 3D printing ecosystem can be very challenging. For Krones, UltiMaker was the right choice thanks to its agile, open and secure solutions. UltiMaker 3D printers have been known for their reliable and consistent quality. UltiMaker’s software comes with print profiles for hundreds of materials and brands, making it easy to pick the right material for the job. However, Krones was in need of a custom material with extremely specific requirements. Thanks to UltiMaker’s open materials platform, Krones was able to develop its own material for its own parts and create reliable print profiles.

UltiMaker’s professional software also helped Krones to meet the data protection standards set by IT. Print jobs on location are securely monitored by Krones through a custom software solution, assuring customers of the quality of the print job. Regular software and firmware updates also ensure Krones utilizes a future-proof 3D printing ecosystem.

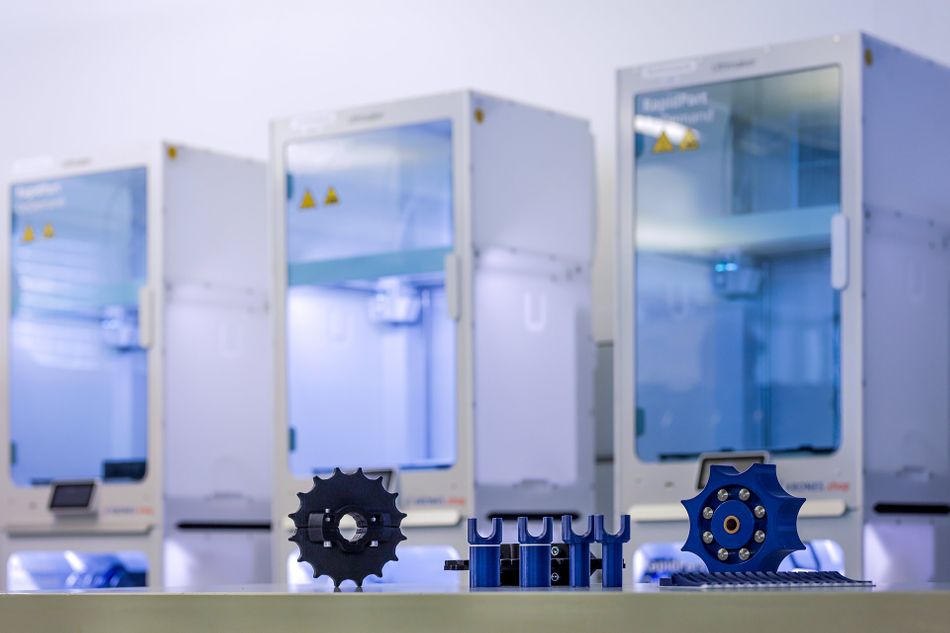

Moving forward with the Factor 4

Krones has been printing in over 10 locations using a large fleet of nearly 50 UltiMaker S5 and UltiMaker S7 printers. Adding the recently launched UltiMaker Factor 4 to its repertoire has brought new possibilities to Krones.

Johannes Karl, Head of Customer 3D Solutions, at Krones, stated:

We’re excited about the potential of the Factor 4. The Factor 4 has taken our capabilities to the next level. With support for stronger and more durable materials, we're able to produce parts that are not only tougher but also offer greater flexibility with softer materials.

The new UltiMaker Factor 4 has a direct drive printhead. This makes printing soft materials easier and even more reliable. Because of the direct drive, the Factor 4 enables users to print parts in even softer and grippier materials. These features bring new opportunities for example for grippers, flexible parts or protective parts.

The new UltiMaker Factor 4 can also print at even higher temperatures, in a better isolated build chamber. This enables engineers to use materials such as UltiMaker’s PPS CF. A material that can easily substitute for PEEK or even steel.

The new features of the Factor 4 push innovation at Krones even further, helping them to deliver even more service to their customers.

Bernd Baldauf, Head of Global eBusiness - Global Digital Content Management - Global 3D Customer Solutions, at Krones, concluded:

Our goal is to grow closer to our customers and become their solution partner. Providing rapid, high-quality parts on demand, and continuously improving our service offerings in Krones quality. With UltiMaker's innovative solutions, we're well on our way to achieving that.