Make It Real 3D Printing Challenge

New 3D printing materials will help you turn your ideas into reality.

The Make it Real Challenge has now closed. We'll be announcing the finalists shortly! Stay tuned to our social media for updates.

Submit your idea:

Do you have a product, part, or concept that you want to bring to life? Wevolver and polySpectra invite designers, inventors, and engineers from across the world to submit ideas to the Make It Real 3D Printing Challenge. polySpectra will help the winners turn their ideas into reality using production-grade additive manufacturing.

The winner will receive $25,000 worth of polySpectra’s production additive manufacturing services to turn their submission into a functional product. We'll first provide some background about the specific 3D printing technique and materials, and then explain details about the challenge and how to submit. Good luck!

Background

Additive manufacturing, commonly known as 3D printing, has been a part of turning ideas into reality for decades, but the material limitations of the process have restrained the technology’s ability for true ‘end-use’ applications, confining it mainly to the prototyping and ideation stages. Most 3D printing processes cannot fabricate parts with the aesthetics, durability, and reliability of traditional manufacturing processes.

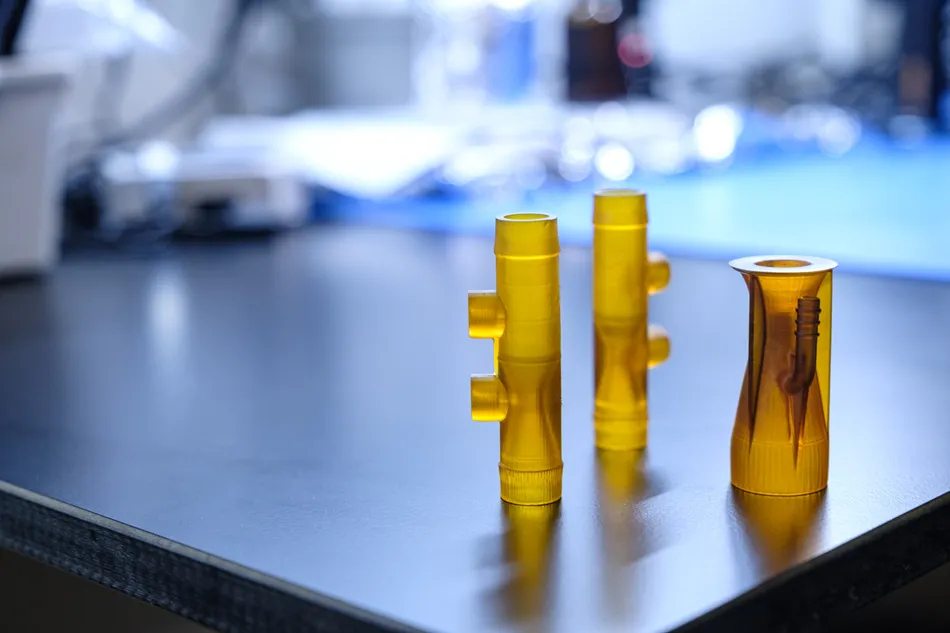

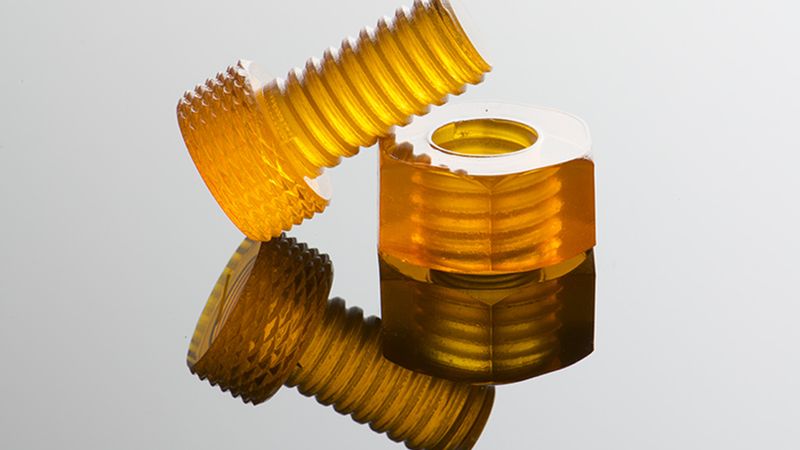

polySpectra, a Berkeley-based startup, has developed a family of functional materials for advanced 3D printing that have comparable properties to molded engineering polymers. Their new material, COR Alpha, is the most rugged 3D printing polymer available on the market today. COR Alpha offers the quality and strength of a molded part with the complex geometry and customization of 3D printing.

COR Alpha printed parts have:

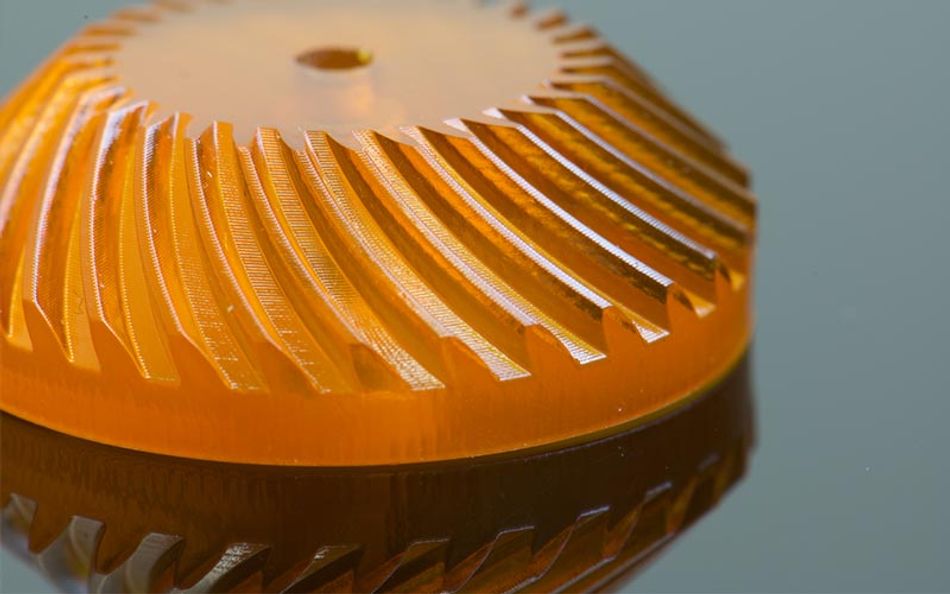

A high-quality finish

High heat resistance

Strength and durability comparable to engineering thermoplastics

Resistance to solvents

3D printing with COR Alpha opens possibilities for designers to produce objects that are impossible to manufacture any other way, either because of the prohibitive costs of injection molding, their complex geometries, or the need for customization.

The applications for COR Alpha are incredibly broad and can take advantage not only of the material properties of COR Alpha, but the agility and customization, and potential utilization of lattices or other lightweight geometries that 3D printing offers.

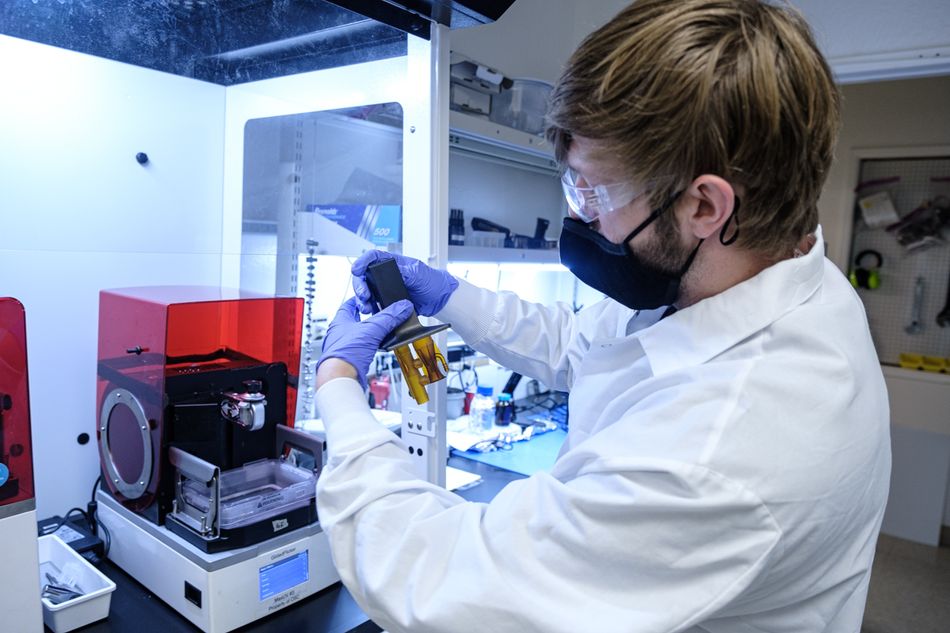

polySpectra prints COR Alpha using DLP (Digital Light Processing) printing, one of the seven main types of 3D printing. DLP printing is widely considered to be the technology most capable of reaching the highest standards in terms of part complexity and precision. To get a more in-depth understanding of DLP printing, check our previous articles here.

polySpectra and COR Alpha

COR Alpha is special within the additive manufacturing industry as it brings the quality and strength of injection-molded polymers to 3D printing. Unlike other photopolymers, COR Alpha is super robust, being able to withstand heat, solvents, pressure, and impact with minimal loss of form or color. COR Alpha is made from Cyclic Olefin Resin, a new product based on discoveries made by polySpectra’s founder, Raymond Weitekamp during his Ph.D. research at Berkeley.

A starting point for thinking about COR Alpha applications includes, but is no way limited to, electronics connectors and housings, enclosures, robotics components and end-effectors, prosthetics, fluidic components, brackets, mounts, fixtures, gears, and venturi valves.

polySpectra is dedicated to helping designers, inventors and engineers make their ideas real. They offer a full service, working closely with design teams to prepare models, offer insights into geometry and design considerations, and can help teams select the best material for their product. Their specialized understanding of both chemistry and 3D printing offers design teams a supportive entry to making their ideas real.

How will you use COR Alpha?

Together with Wevolver, polySpectra is launching a global design challenge to search for innovative applications of COR Alpha.

Wevolver and polySpectra invite designers, makers, and thinkers from across the world to submit ideas to the COR Alpha Design Challenge and make their ideas real.

We are looking for design teams, engineers, inventors, startups, and fledging companies that are designing products and ideas that can be amplified by COR Alpha printed parts.

The brief:

Submit a design for a stand-alone product or a component of a larger design. The winner should be able to provide a compelling explanation of how they are utilizing the characteristics of COR Alpha and demonstrate how COR Alpha can make their ideas real. Judging criteria will also include creativity and fit for additive manufacturing.

Parts must fit into a 190mm x 120 mm x 200mm build envelope.

Team must be available during the challenge to collaborate with polySpectra and Wevolver.

The prizes:

The winner will receive $25,000 worth of polySpectra’s production additive manufacturing services to turn their submission into a functional product. Depending on the stage of the project at submission, that winning package will include a combination of:

Mentorship,

Design for Additive Manufacturing Consulting,

Functional Prototyping,

Qualification,

Testing,

& Production Parts Fabrication.

Winners will work closely with the polySpectra team to develop their submission and make it ready for printing and application into their project.

Submit to the challenge

Fill out this short form by September 28 2020 before 12pm (PT). We ask that you provide us with the following:

1. Personal details.

2. Describe your submission idea and its intent. (up to 500 words).

3. Submit images that strengthen your submission – e.g. screenshots, illustrations, drawings. (Up to 5 images. Max file size 10 MB)

Stay informed about the Make it Real Challenge

Watch the webinar with polySpectra founder, Raymond Weitekamp, to learn about the possibilities and design considerations of COR Alpha.

Submit a question about COR Alpha or the challenge here.

Check out some of the recent submissions to the challenge here.

Stay tuned on updates on Wevolver.com

Key Dates

| Event | Date |

| Design Challenge Launch | Monday 11 August |

| Webinars with polySpectra founder | Watch the replay of our first webinar about COR Alpha here. Learn more about how polySpectra assisted an open-source ventilator project by watching our second webinar here. Or reading the wrapup here. |

| Submit your entry (on or before) | 28 September 2020 |

| Shortlisted winners announced. | October 2020 |

| Winners announced | November 2020 |

Do you know someone with a great idea?

Nominate them for the Make it Real 3D Printing Challenge and they could win $25,000 of additive manufacturing services.

If you nominate the winner you’ll receive a $300 Amazon gift card.

Nominate them here.

Need anything else clarified?

You can read more in-depth info about the COR Alpha material in this article.

Also, feel free to get in touch with us: Email: jessica (at) wevolver.com

About the sponsor: polySpectra

polySpectra is an advanced materials company on a mission to transform polymer 3D-printing from a prototyping aid into a production manufacturing tool. polySpectra has developed a new class of modular light-activated resins, unlocking a broad spectrum of tailored engineering properties for production-grade additive manufacturing. We call this new family of additive materials COR, for Cyclic Olefin Resin. polySpectra’s first material, COR Alpha, demonstrates an unmatched combination of thermal, mechanical and chemical properties that enables additive manufacturing to compete with injection molding. polySpectra's technology is based on more than five years of chemical research and development at two leading research institutions: Caltech and Lawrence Berkeley National Laboratory. Based in Berkeley, CA - polySpectra helps inventors, designers and engineers make their ideas real.

About polySpectra

polySpectra makes functional materials for advanced additive manufacturing. We use light-activated catalysts to 3D print advanced functional materials. Our modular platform enables us to deliver...

14 Posts