New Horizons in Additive Manufacturing Technology: Utilizing Nanomaterials in 3D Printing

3D printing materials filled with precise quantities of nanoparticles are making a profound impact on industries like electronics, healthcare, and aerospace

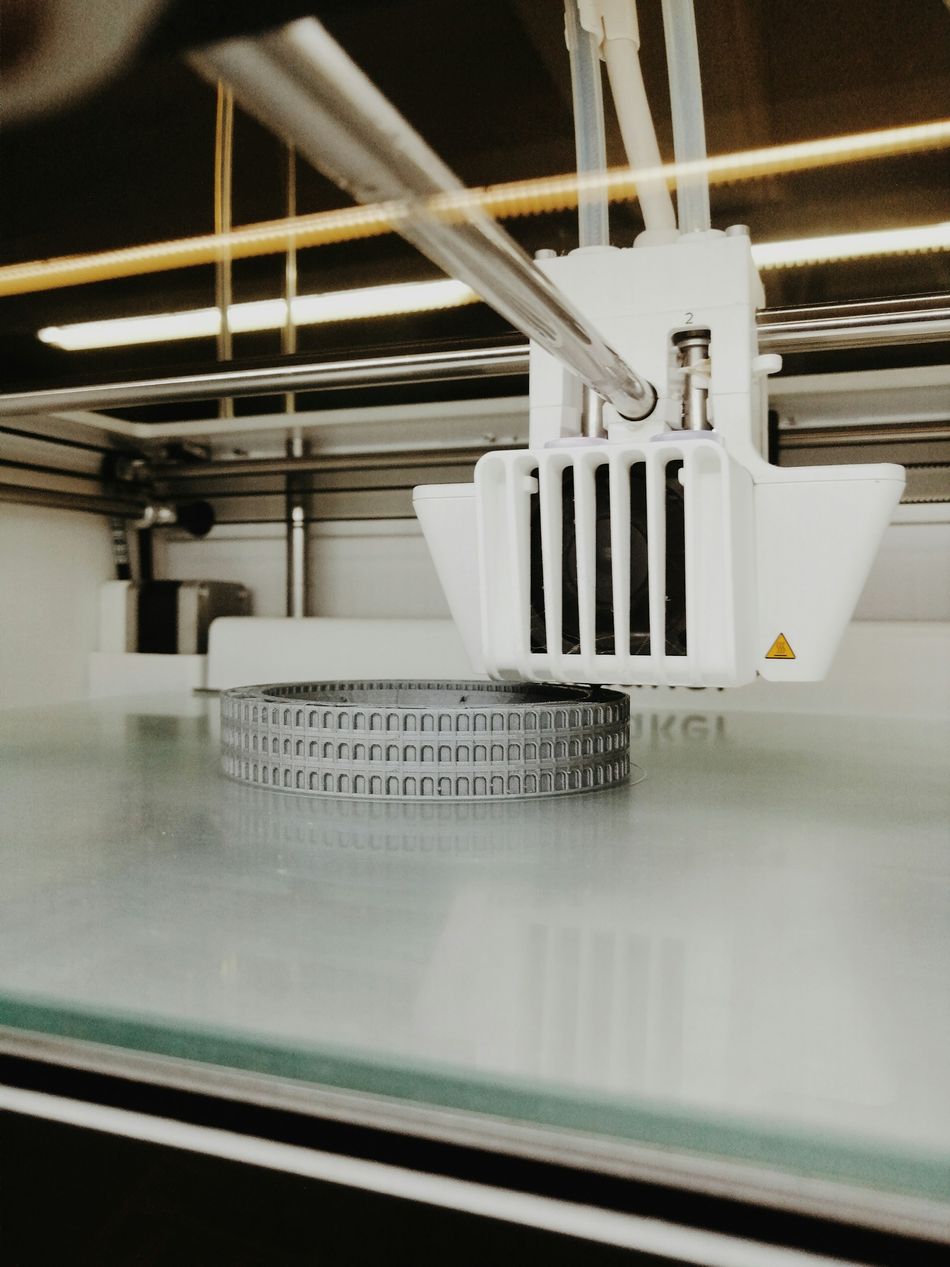

3D printing, also known as additive manufacturing, is a relatively new but rapidly maturing production method that is transforming how products are developed and manufactured across industries like healthcare, aerospace, energy, and electronics. The technology, which dates back to the 1980s, is based on the principle that components are constructed additively rather than subtractively, which results in benefits like greater design freedom and less material waste.

Historically, 3D printing has primarily been used as a prototyping technology, allowing for the rapid iteration of physical prototypes from a 3D CAD model without the need for any costly tooling. Today, however, the technology is increasingly being used for end-use applications in addition to prototyping, as the quality of the manufacturing processes improves and material options continue to grow.

When talking about 3D printing materials, you’d be forgiven for first thinking of spools of thermoplastic filament or vats of photopolymer resin. While these are among the more common types of 3D printing consumables, there are actually a wide range of additive manufacturing processes that require different types of materials, from thermoplastic filaments, to photopolymer resins, to polymer, ceramic, and metal powders, to nanomaterials.

What Are Nanomaterials?

Today, nanomaterials are at the frontier of additive manufacturing technology as they allow for the production of parts with superior properties compared to neat materials. In the simplest terms, nanomaterials are made up of a matrix material, such as a polymer, which is embedded with nanoparticles (measuring between 1 and 100 nanometres in diameter). The nanoparticles used in nanomaterials or nanocomposites can vary and the type of nanoparticle plays a central role in determining the properties and functions of the material in question.

For example, there are different categories of nanomaterials including: carbon-based nanomaterials that are filled with carbon nanotubes or graphene and are notable for their conductive properties; metallic nanomaterials with silver or gold nanoparticles; semiconductor nanomaterials like quantum dots; and ceramic nanocomposites with insulating and strengthening properties. Typically, these nanoparticles are contained within a matrix material of polymer, metal, or ceramic, which can be used in various 3D printing technologies.

3D Printing Nanomaterials: Challenges and Outlook

Unlike more conventional nanomaterial production methods, like chemical vapour deposition (CVD), 3D printing offers a number of benefits, including more complex geometries, greater customization, and more control over material distribution. There are several different additive manufacturing processes that can use nanomaterials, including directed energy deposition (DED), fused filament fabrication (FFF), powder bed fusion (PBF), photopolymerization processes like stereolithography (SLA) and digital light processing (DLP), and material jetting.

Among the main challenges of bringing nanomaterial 3D printing more into the mainstream is achieving uniform dispersions of nanoparticles in the matrix material. This is a challenge across different additive manufacturing processes, including extrusion, resin, and material jetting technologies, since nanoparticles can agglomerate in the matrix, which can result in inconsistent results and uneven material properties. If you can imagine a 3D printed wound dressing where the antimicrobial properties are concentrated in just one area, you can understand the severity of this challenge. Other challenges are associated with how the addition of nanoparticles can alter the printability of materials, whether the viscosity of an ink, the curing properties of a resin, or the abrasiveness of a filament. On top of that, the processing conditions, such as temperature and speed, need to be precisely controlled in the 3D printing process to prevent the degradation of nanomaterial properties.

Presently, the use of nanomaterials or nanocomposites in 3D printing technologies is still largely limited to the research realm. However, the potential applications for the materials in the 3D printing process are highly promising. For example, integrating silver nanoparticles into a 3D printed structure could add antimicrobial properties useful for applications like medical implants and wound dressing.[1] Graphene nanoparticles and carbon nanotubes, for their part, are being investigated for their ability to add conductive properties to parts made using FFF 3D printing.[2] And at a university in Oklahoma, researchers are investigating the use of flame-retardant nanoparticles in a biopolymer matrix to make certain plastics more fire resistant.[3]

Despite the fact that 3D printing nanomaterials is still a nascent field, there are commercialized products that integrate nanoparticles. SLA specialist Formlabs, for example, sells a nano- ceramic filled Class II biocompatible material for the dental industry. The photopolymer resin offers superior strength and wear resistance thanks to its ceramic nanoparticles.[4]

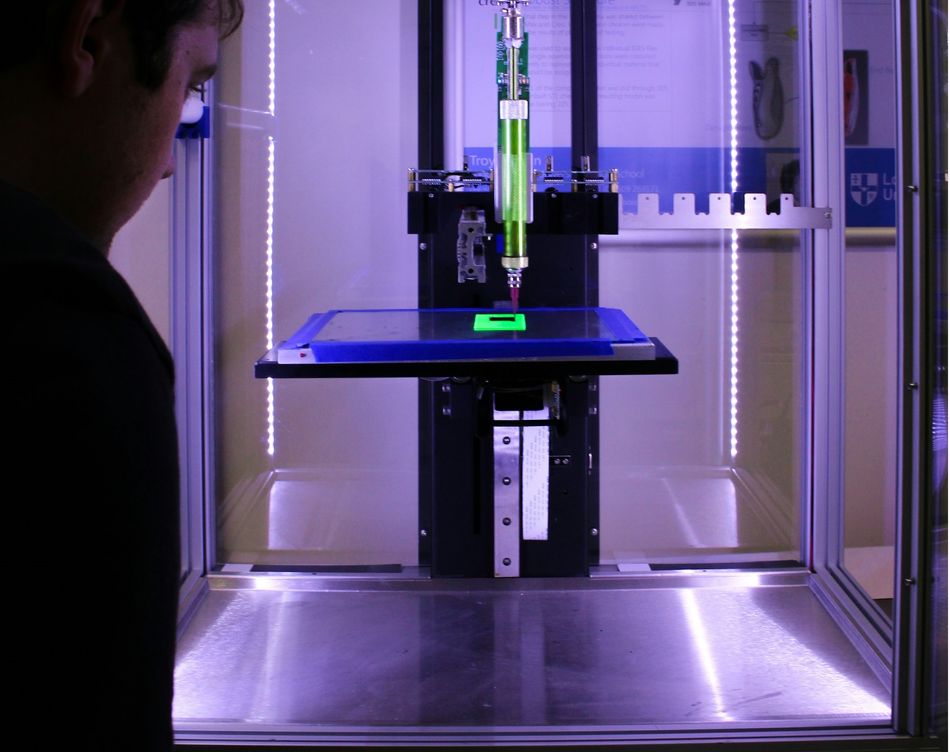

Nanomaterial additive manufacturing technology is also expanding into areas like microelectronics, facilitating the fabrication of complex, miniaturized components with enhanced electrical conductivity and mechanical properties using a combination of conductive and dielectric nanomaterials. Companies like XTPL are leading on this front, bringing to market a range of conductive inks and pastes as well as a precision dispensing process for creating miniaturized electrical circuits.

The Future of 3D Printing is Nanomaterials

These applications are just the tip of the iceberg: as it advances, nanomaterial additive manufacturing can and will transform 3D printing applications in industries like healthcare, aerospace, and electronics through the development of stronger, more lightweight components as well as products with unique characteristics, like antibacterial properties, conductivity, and more.

Resources

[1] Astaneh ME, Fereydouni N. Silver Nanoparticles in 3D Printing: A New Frontier in Wound

Healing. ACS omega. 2024 Sep 16;9(40):41107-29.

[2] Bajpai A, Jain PK. Investigation on 3D printing of graphene and multi-walled carbon

nanotube mixed flexible electrically conductive parts using fused filament fabrication. Journal of

Materials Engineering and Performance. 2023 Jul;32(14):6319-28.

[3] OSU research focuses on improving fire safety in 3D-printed materials [Internet]. Oklahoma

State University, January 30, 2025. https://news.okstate.edu/articles/engineering-architecture-

technology/2025/

osu_research_focuses_on_improving_fire_safety_in_3d_printed_materials.html#h_6010598121

71738267359042

[4] Formlabs’ Premium Teeth Resin Receives FDA 510(k) Clearance for Temporary Crowns and

Bridges [Internet]. Formlabs, August 6, 2024.

https://dental.formlabs.com/company/press/premium-teeth-resin-receives-fda-clearance-

temporary-crowns-and-bridges/