Optimum water treatment with 3D wire mesh filter elements

Whether for the development of a self-sufficient energy system in Namibia, for wastewater treatment in Norway or for seawater desalination in drought regions – for complex water treatment processes, plant engineers around the world rely on filter media made of wire mesh.

Precise mechanical filtration is crucial for efficient, economical and sustainable water treatment – because the more solids down to the finest microplastics can be separated directly, the lower the need for further cleaning processes. The associated energy and space savings and the reduced use of chemicals cut costs and protect the environment.

Why filter elements of woven wire mesh?

Metal wire mesh offers a whole range of advantages that make it almost unbeatable as a filter medium in water treatment. With their excellent mechanical properties, they reliably remove the finest particles down to 5 µm and can therefore contribute to the best possible separation of unwanted foreign substances such as suspended organic matter or microplastics.

Thanks to their high flow rate and high dirt holding capacity, they increase the efficiency, safety and stability of filtration processes. The decreased blocking tendency, in comparison to alternative filter media – such as fleece – and the optimised regenerability enable plant operators to extend cleaning intervals and reduce the burden involved in mechanical and chemical cleaning. The combination of mesh type, weave type as well as the suitable support and drainage layers can be used to create numerous configurations and simulate the respective behaviour.

Ultra-fine filtration with MINIMESH® S filter mesh

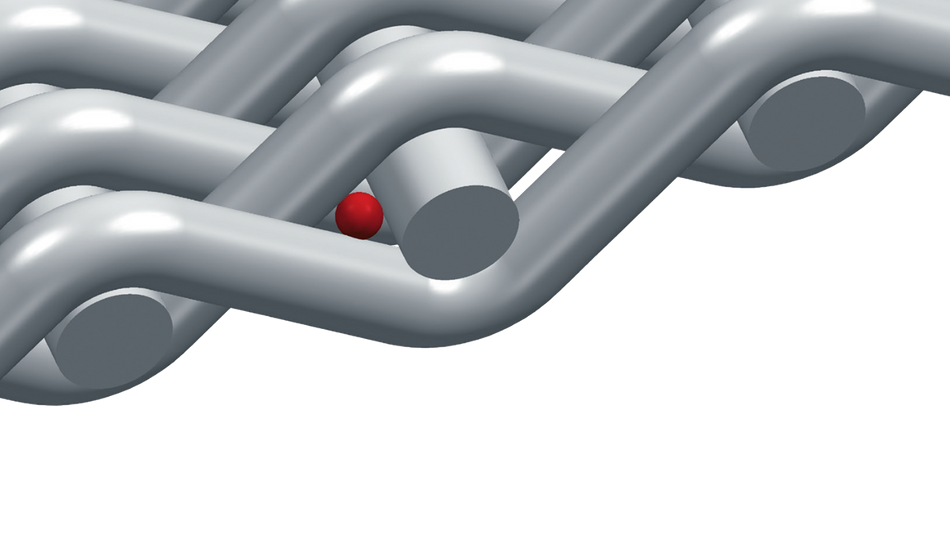

With metal wire mesh, a distinction is made between open square or rectangular meshes and optically closed dutch weave types. In various water treatment systems in which particles down to the micrometre range from 5 μm must be filtered out precisely and economically, the use of MINIMESH® S Dutch weave as a filter layer has proven its worth.

In plain dutch weaves, the warp or weft wires are woven so close together that they are called zero aperture meshes. In contrast to classic mesh sizes, these meshes have what are known as geometric pore sizes, defined by the diameter of a sphere that can just pass through the filter cloth. Both the geometric pore size and the permeability can be precisely calculated so that the filtration behaviour can be simulated before production.

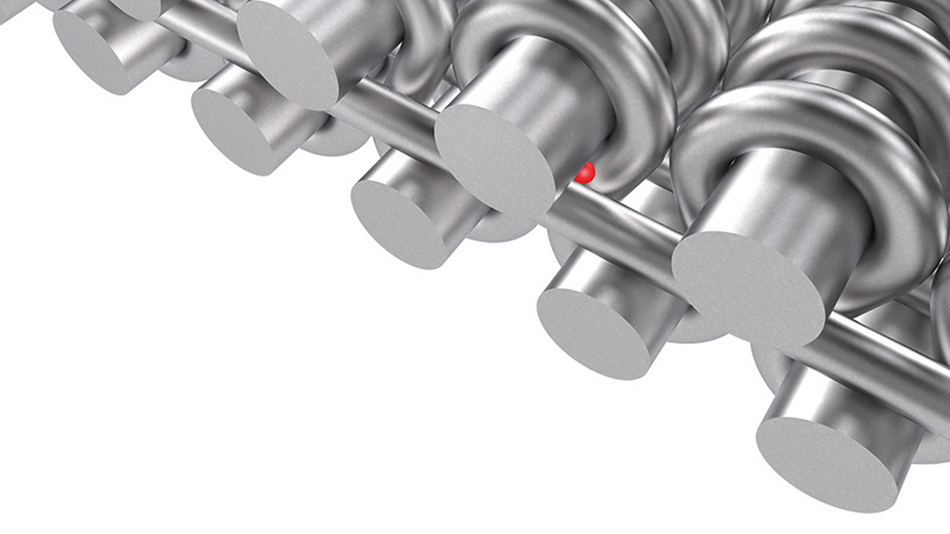

MINIMESH® RPD HIFLO-S for water treatment

Especially in ultra-fine filtration, innovative 3D filter media also open up completely new possibilities: Thanks to their three-dimensional pore geometry, their dirt-holding capacity and flow rate are maintained for significantly longer than with conventional filter media. In addition, special materials can also be woven in the small pore spectrum, making highly corrosion and temperature-resistant filter meshes available in the ultra-fine range for the first time.

Haver & Boecker filter cloths in use

Filter cloths from Haver & Boecker are already setting new standards in mechanical water treatment in many successful projects:

- In Namibia, the jointly funded HygO project is being supported by modern hydrogen technology. The aim is to develop a self-sufficient energy system in the form of so-called microgrids. The HygO microgrid also features an additional circuit for biological-mechanical water treatment, in which intermediate MINIMESH® RPD HIFLO 5-S filter cartridges retain particles from 5 µm.

- In Norway, the start-up renasys is demonstrating how innovative microscreen systems can significantly reduce the energy consumption of wastewater treatment plants. By using MINIMESH® RPD HIFLO 5-S filters, up to 99% of the dirt particles are removed before the actual clarification process.

- For seawater desalination in drought regions, the use of MINIMESH® S filter cloths in the pre-treatment of the water ensures efficient and long-lasting filtration, which significantly extends the service life of the RO membranes and reduces operating costs.

Whitepaper: New dimensions in water treatment

With their excellent mechanical properties, filter elements made of metal wire mesh reliably remove contaminants and can be optimally adapted to the requirements of the respective application. Further details on the specific advantages and areas of application of our wire mesh solutions can be found in our free whitepaper:

- Mechanical treatment as a decisive factor

- Advantages of metal wire mesh for water treatment

- Ultra-fine filtration with MINIMESH® S filter mesh

- Application examples from practice

- Filter elements for the highest mechanical loads