Plastic that meets medical needs

There’s a lot to think about when it comes to plastics for medical parts. At the top of the list are safety and, for parts going inside the body, longevity. So, which is the best to choose for your application?

A quality technician examines a plastic part in a clean room during the medical moulding process to ensure precision and repeatability.

Designing medical parts? Just as there are countless types of medical procedures, there are also countless types of polymers on the market today. Which ones are best for your medical application? Great question. We’ll attempt to provide some guidance in this design tip, but it’s important to start with the following caveat: The term “medical grade” is ambiguous at best.

Medical device manufacturers must understand and comply with a slew of standards, but for the purposes of this discussion, ISO 10993 takes the lead role. It has nearly two dozen parts, of which four pertain specifically to material selection; of these, ISO 10993-13 is probably the most relevant to polymers.

Unfortunately, there’s no catalogue or book that lists which polymers meet which standards, or even which polymers are biocompatible. Compounding matters is the sheer number of resins, pellets, powders, and bulk forms like rod and sheet from which to choose, each with multiple manufacturers that may or may not meet the necessary medical device requirements. Where one might provide medical-grade ABS, the other produces ABS suitable for LEGOs and power tool housings.

Of course, one blog post can’t cover all you need to know about medical grade plastics, so don’t forget you can look at the stats on our materials comparison page. All that said, here are six essential polymers to keep in mind for your next medical parts project.

Comparing Plastics for Medical Parts

Generally, medical device designers and manufacturers should look for polymers that are resistant to corrosion, chemical attack, and high temperatures. These should be non-absorbent and inert, and able to withstand repeated sterilisation cycles in an autoclave. Of course, they shouldn’t react with bodily fluids and human tissue, cause irritation, or create skin sensitivities. Did we mention strength and durability? All of this might seem like a very tall order, but the good news is that a healthy handful of polymers check at least most of these boxes.

PC

Oftentimes, an optically transparent polymer is needed for medical procedures, and polycarbonate is the material of choice. It checks all the usual boxes in terms of toughness, dimensional stability, heat and chemical resistance, and sterilizability. You won't find it inside the human body, but PC is typically used when it's necessary to see blood, drugs, and other fluids flowing through a device. Many of Protolabs' medical customers will 3D-print their designs from PC-like materials such as Acura 5530 or PerFORM, then go on to machined or injection-moulded polycarbonate as production needs increase.

UHMW-PE

Since we’re discussing orthopedic implants, here’s another important polymer to keep in mind: ultra-high molecular weight polyethylene. If you’ve had a knee or hip replacement, chances are good that you have some of this stuff inside you. UHMW-PE is an extremely dense, low-friction member of the polyethylene family. If you’re looking for some machined medical components (or wear-resistant machinery parts), UHMW-PE has excellent impact strength and abrasion resistance, and here again, is eminently biocompatible. And for slightly less demanding applications, “regular” polyethylene (PE) and high-density polyethylene (HDPE) are good, all-around polymers for a wide range of medical applications, especially for single-use products and the PPE gear that’s become so prevalent over the past few years.

PEI

Like PEEK, polyetherimide borders on super-polymer territory. Better known by its trade name Ultem, PEI is a rigid, semitransparent, and heat-resistant 180°C polymer that is amber in colour and boasts great tensile strength. Because it also has high dielectric characteristics and resistance to flame, it is widely used in electronic components, medical or otherwise. We machine and injection mould PEI into various shapes, with potential uses including handles for surgical instruments, medical device enclosures, insulators, electrical connectors, and more. Lastly, PEI is readily sterilised via autoclaving and gamma radiation.

PSU

Another amber-coloured polymer is PSU, short for polysulfone. Recognised for its toughness and rigidity at elevated temperatures, PSU is less strong than PEI but more impact resistant. It might be machined or moulded into filter housings, catheter ports, surgical instrument trays, and sizing devices for use during heart valve replacements. Polysulfone is said to be one of the few polymers able to withstand more than 1,000 cycles of steam sterilisation (as can PEEK and PSU’s even more impact- and heat-resistant cousin, polyphenylsulfone, or PPSU).

PEEK

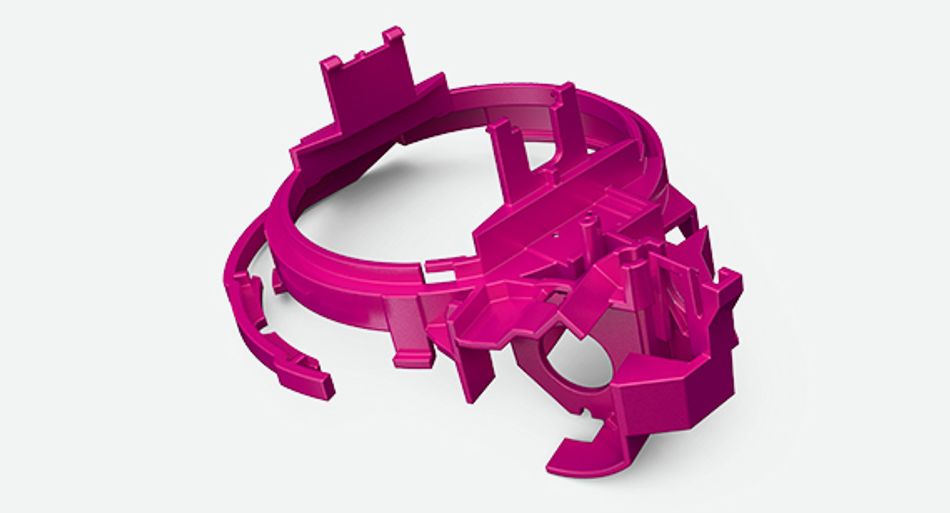

Polyetheretherketone is a great place to start. Long considered an “engineering-grade” thermoplastic, PEEK enjoys broad use in the medical industry. Orthopedic surgeons use it for trauma fixation, spinal implants, and replacement joints, while dentists use it in crowns and bridges. PEEK is both lightweight and strong, is radiopaque (meaning it appears on x-rays), and maintains its strength and dimensional stability at high temperatures. And seeing that PEEK is often inserted into the human body for extended periods of time, it goes without saying that it’s biocompatible and sterilisable. Protolabs routinely CNC machines and plastic injection moulds PEEK into mechanical components such as gears, bearing surfaces, and manifolds, as well as a host of medical parts.

Silicone

The stuff of weatherproofing adhesive and cooking utensils, silicone is also an excellent choice for many medical components. Silicone is available in various hardness levels, from soft and stretchy like a rubber band or rigid like a tire tread. It withstands temperatures from sub-zero to oven hot 55°C to 210°C, is hydrophobic (repels water), resistant to solvents and acids, and has good vapour permeability, making it a favourite for prosthetic devices. Protolabs 3D-prints a variety of medical components, including seals, gaskets, and surgical models, and injection moulds all manner of prototypes and end-use production parts using liquid silicone rubber (LSR). You can even 3D print in silicone, a great option for prototyping parts using this material for complex parts or prior to moving to injection moulding for production quantities. In addition, there’s also an optical grade of liquid silicone rubber, OSLR, which enjoys superior refractive and light transmission properties compared to its PC or PMMA (acrylic) alternatives. It is therefore popular for use in lenses and lighting applications, or anywhere that a clear, non-yellowing, heat- and chemical-resistant biocompatible polymer is needed.

More Options to Consider

Those six medical-grade polymers are just the starting point. We’d be remiss if we didn’t mention PTFE, better known as Teflon, a super-lubricious polymer used in everything from catheters and stents to heart-lung machines. Impact and chemical-resistant acrylonitrile butadiene styrene (ABS) is sometimes used to replace metal structural components in medical equipment, as is acetal (you might know it as Delrin), while polyvinyl chloride (PVC) might be considered a flexible version of polycarbonate in certain applications. Polyethylene terephthalate (PET) resists attacks by microorganisms, making it just as suitable for soft drink containers as it is for wearable sensors. Polypropylene (PP)—although considered a commodity plastic—finds widespread use in specimen bottles, prescription containers, and disposable hypodermic syringes (it’s also a great option for parts that would benefit from a living hinge).

As with any manufacturing application, choosing the best material for a medical device comes down to its physical, chemical, and electrical requirements, not to mention its operating environment. There’s also manufacturability to consider and all the design rules that go along with that. And at the end of the design and prototyping process waits the FDA approval ordeal. It can be a confusing landscape to navigate, which is why we encourage you to upload a file, get a quote, and give us a call to discuss your options. We've helped countless others who were once in your shoes.