Predictive Maintenance vs. Predictive Resolution

Manufacturers are already gaining reduced downtime and cost savings with predictive maintenance. In addition to root cause analysis and predictive maintenance, predictive resolution has a much more sweeping scope in finding and fixing problems beyond machines.

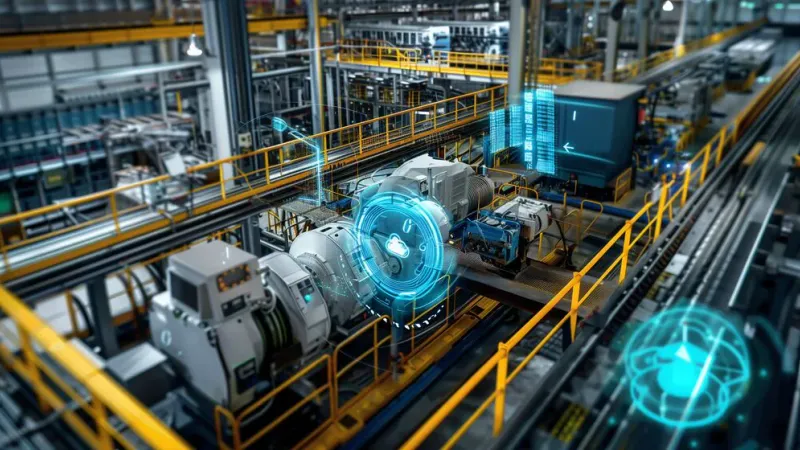

Source: William / stock.adobe.com; generated with AI

This article was first published on

www.mouser.comQuality control in manufacturing is no easy task and too often involves learning from hindsight. By the time parts churn off the assembly line and undergo inspection, it might be too late to catch problems. Waiting until the tail end of the manufacturing process to ensure defect-free products wastes a lot of resources, time, and money.

But there is an effective alternative.

Imagine, for example, a welding process where a thermal camera closely tracks the heat signature of the product as it is being manufactured. If the part is being welded incorrectly, an alert goes off immediately so the process can course-correct in real time. Such game-changing efficiencies in manufacturing are beginning to take root, based on advanced technologies like machine learning (ML), and are part of an overarching investment in predictive resolution.

The Evolution of Predictive Maintenance

If the term predictive resolution sounds familiar, it might be because it's closely related to its more familiar cousin: predictive maintenance.

The speed with which data-driven technologies have shaped manufacturing in just a few short years is astonishing. Iterations of newer evolutions of digital transformation, like Industry 4.0 and Industry 5.0, have benefited the sector in many ways, especially in facilitating predictive maintenance.

Predictive maintenance is one of the primary tenets of Industry 4.0 and runs on the theory that we can use data about equipment health to prevent serious failures before they happen. By studying machines' vibration or heat signatures and inputting this data into ML models, manufacturers can tell when equipment will fail and intervene to avert disaster. Such proactive corrections save expensive downtime, traditionally a significant challenge in the sector.

Moving to Predictive Resolution

Predictive maintenance is a subset of predictive resolution. The same vast suite of advantages that predictive maintenance delivers applies to predictive resolution. But the two are different in a few fundamental ways.

Predictive maintenance tells manufacturers when equipment is about to fail. Predictive resolution goes a few steps further and suggests ways to fix the problem. So, while predictive maintenance addresses the ifs and whens, predictive resolution tackles the hows.

Predictive maintenance has a much tighter focus, with its sights set on manufacturing equipment. Predictive resolution, on the other hand, covers most business operations—from supply chain management to worker scheduling and process improvements, in addition to equipment health. The welding operation fix using thermal cameras mentioned earlier is an example of predictive resolution addressing process inefficiencies. Machines with real-time monitoring equipment can address production line delays immediately and fix bottlenecks to meet daily and even hourly production quotas.

Predictive resolution does not just find what is wrong with manufacturing equipment; it finds—and suggests fixes for—what is not working throughout relevant business operations.

The Technology and Infrastructure Driving the Evolution

Where manufacturing was an opaque process before, digital transformation and data have made operations more transparent. As a result, it's easier to find and fix inefficiencies.

Arguably, one of the biggest game-changers for the industry has been developing and deploying IIoT sensors at scale. When machines have sensors, they can "communicate," and manufacturers can use that information to make data-driven decisions. But IIoT alone is not enough. The sheer glut of data the IIoT generates can easily lead to manufacturers drowning in too much information. However, technologies such as AI help OEMs make sense of the data. When fed into predictive ML models, the data is able to deliver predictive maintenance.

Now, the breaking of data silos between various departments in a manufacturing company, along with the ability to read unstructured data, is leading to further advancements in how the industry makes data-driven decisions—through predictive resolution.

And the efficiencies have moved beyond machines on the production floor. Generative AI models can train on proprietary information stored in manuals, equipment maintenance logs, emails, and more to create training modules for employees using natural language processing (NLP). Less experienced workers can query generative AI models to access repair instructions and record logs in a central location, so data is not locked and siloed.

The Future Impact of Predictive Resolution

One of the biggest challenges for the manufacturing sector has traditionally been usable and relevant data availability. Now that the technologies are in place, expect predictive resolution to help manufacturers in a variety of new and unique ways.

The use cases for predictive resolution abound.

Product servitization, for example, where OEMs lease instead of sell equipment, can use predictive resolution for a steadier source of revenue. Manufacturers can access data from this leased equipment to further fine-tune predictive AI models.

Conclusion

Manufacturers are already gaining reduced downtime and cost savings with predictive maintenance. In addition to root cause analysis and predictive maintenance, predictive resolution has a much more sweeping scope in finding and fixing problems beyond machines. OEMs who have paved the way with digital transformation stand poised to reap the benefits from this holistic approach.

About Mouser Electronics

Mouser Electronics is a worldwide leading authorized distributor of semiconductors and electronic components for over 1200 industry-leading manufacturers. We specialize in the rapid introduction of...

202 Posts