Robotic Arms for Underwater Applications

RE2 Sapien Sea Class™

SITUATION

Numerous industries rely on commercial divers to conduct underwater maintenance and repair tasks, including the maintenance and inspection of offshore oil rigs and pipelines, and the construction and repair of bridges, piers, and dams. With two-thirds of the earth’s surface covered in water, the commercial diving industry is a high-demand profession—and it is also one of the most hazardous for workers. Therefore, there is great potential for robotic systems to enhance worker productivity and safety, and to assist in the exploration of oceans and waterways.

PROBLEM

The U.S. Occupational Safety and Health Administration (OSHA) classifies commercial diving as a high-risk occupation, reporting that the industry has a “very high rate” of fatality and injury. Commercial divers often need to use machinery, tools, or materials that can expose them to hazards such as electrocution, burns, explosions, respiratory distress, or drowning. These risks are exacerbated by the need to work for extended periods of time in water with low visibility, constrained environments, or frigid temperatures. In addition, the extended exploration or inspection of marine objects is limited to the amount of time that divers can safely remain underwater, including the time it takes for divers to descend and resurface to rest and replenish their air tanks. Due to the strenuous nature of the work, commercial diving also has a high turnover rate— skilled divers typically don’t work past the age of 45, requiring younger, less experienced divers to be trained on a regular basis.

SOLUTION

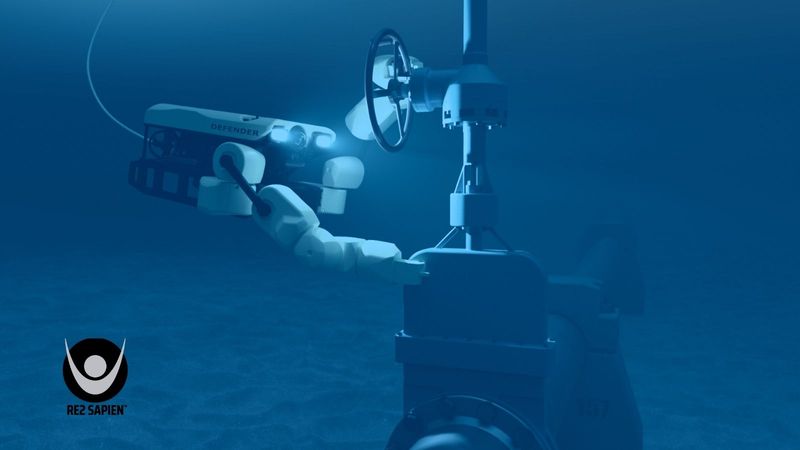

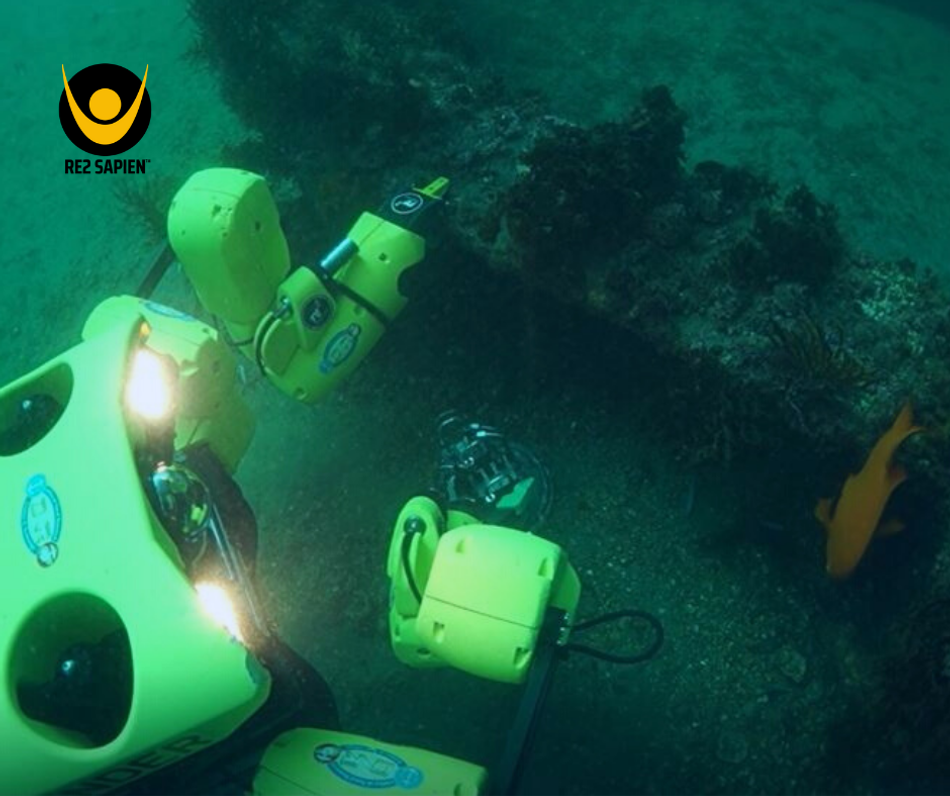

Originally engineered for the U.S. Navy to operate in harsh marine environments, RE2 has developed a dual-arm, highly dexterous, electronically driven manipulation system designed for deep ocean use. RE2 Sapien Sea Class™ dual-arm system featuring two 6-degree-of-freedom arms that easily integrate with numerous remotely operated vehicles (ROVs) and are used in a variety of industry applications. RE2’s electric, energy-saving system frees up subsea vehicle power to allow cameras and sensors to interrogate the environment for extended periods of time. In addition, the system’s lightweight, compact design allows for a smaller footprint in constricted environments, allowing it to dexterously operate in precarious areas that are difficult, if not impossible for more traditional underwater systems to access. The RE2 Sapien Sea Class provides near human performance at human scale.

RE2 Sapien(TM) Sea Class can reach depths of more than 300 meters.

RE2 Sapien(TM) Sea Class can reach depths of more than 300 meters.The system’s neutral buoyancy ensures that it stays controllable when performing a variety of inspection and repair tasks, even at depth. When both arms are used, the second arm provides stability in less-than-ideal conditions, such as in fast-moving currents; the system’s high degree of dexterity allows one arm to be used to perform a task while the other arm is used to secure the system to an object. To allow for extended subsea interactions, the closed, sealed design of RE2 Sapien Sea Class™ also features a multi-level corrosion management system, which includes the use of sacrificial anodes and anodized joints, providing a very rugged and reliable solution with minimal maintenance. Using a robotic system for underwater inspection and maintenance tasks can also allow older, skilled divers to stay on the job longer, as they may be able to transition to a topside role and use their experience to guide operations, whether through teleoperation or autonomously via RE2’s computer-vision and machine-learning algorithms, RE2 Detect™ and RE2 Intellect™.

How can RE2 Robotics help your team improve worker safety through robotics? Contact us today at underwater@resquared.com.