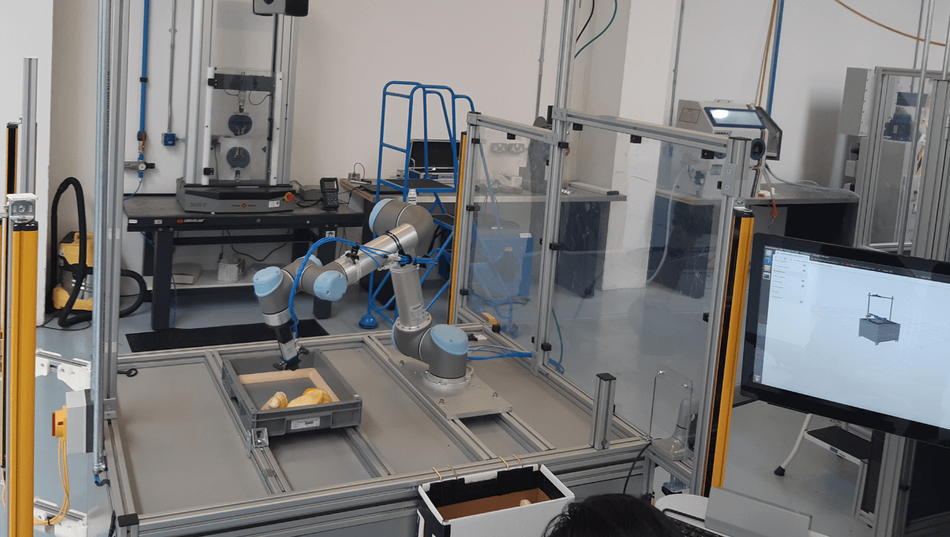

Robotic picking of croissants

The Irish Manufacturing Research developed an advanced solution for automated picking of bread products, which deploys a UR 5 robot navigated by 3D vision and robotic intelligence SW from Photoneo.

Automated picking of bread products

Partner:

IMR – Irish Manufacturing Research

Problem:

Bin picking of randomly oriented parts is of great interest to manufacturers as automation of these processes can save a lot of costs and space. The market offers a large number of bin picking solutions but many of them struggle with recognizing and identifying transparent, deformable, variable , and reflective objects that may even be piled, entangled, and jumbled up.

The Irish Manufacturing Research built a bin picking cell for the picking of 3 different types of randomly oriented bread products.

This project presented several technical challenges:

- Identification and picking of objects of non-symmetrical and complex shapes

- Random orientation of the objects

- Picking of 3 different types of objects

- Achieving optimal process speed

Solution:

Bin Picking Studio + PhoXi 3D Scanner

The solution comprises a bin picking cell with Photoneo robotic intelligence software for bin picking – the Bin Picking Studio, a PhoXi 3D Scanner, and a UR 5 robot. The supplier of Photoneo technology in the UK is Multipix Imaging.

Before implementation, the following setup and configuration requirements needed to be met:

Pre-planning:

- Defining a suitable end-of-arm tooling design

- Mounting an EOAT gripper and testing its operation on the robot

- Ensuring correct safety requirements (Collaborative mode or Industrial mode)

- Having CAD models (in the STL file format) of:

- The product to be picked

- The EOAT gripper

- The cell layout

- Having the required software files of the UR5 robot for integration with the Bin Picking Studio

- Having the required network cables for a physical connection between Bin Picking Studio, UR5, and PhoXi 3D Scanner

- Having an HDMI cable for connection between Bin Picking Studio hardware and the monitor screen

Setup:

After all the above requirements had been met, the next implementation steps were:

- Building the cell and integrating hardware

- Integrating Bin Picking studio hardware and software

- Planning gripper grasping, including all potential grasping orientations and picking points

- Calibration of robot vision and the end-of-arm tooling

- Setting parameters

- Optimization of layout, path planning, and robot parameters

- Repeatability testing

The system enables repeatable picking and emptying of random bins filled with 3 different bread products of complex shapes at a picking rate of 6ppm. If the products had a symmetrical shape, the processing speed would be even faster.

The system enables an easy changeover between different products.

Discussion:

This project provides IMR partners and customers insights into the requirements and capabilities of a typical bin picking solution. IMR has invested in a commercial bin picking solution that Irish manufacturers and IMR partners can avail of.

The system can be further optimized by:

- Setting the robot speed to maximum

- Restricting the robot’s joint motions for shorter trajectories

- Using smart memory and fast scanning option

- Optimizing localization parameters available in the system

- Using grasp invariance feature that allows multiple possible grasp points on the product