Security in 3D Printing: How to Stay Protected from Cybersecurity Threats

In this article, we’ll provide a high-level overview of the best practices from a network perspective down to the individual printers.

This article was first published on

ultimaker.comAs 3D printing continues to be integrated into workflows in industries like manufacturing and healthcare, cybersecurity in additive manufacturing is becoming increasingly crucial.

Recently, we dove into the key factors to consider in 3D printing security. In this article, we’ll provide a high-level overview of the best practices from a network perspective down to the individual printers.

Network and ecosystem security

Whether it’s unauthorized access, data breaches, or malicious firmware modifications, users must stay vigilant. Keeping printers, networks, and digital workflows secure is essential to prevent cyber threats.

Network segmentation and firewalls

Keeping your 3D printers on a separate VLAN or dedicated network, along with implementing a firewall to restrict external access to the network, are efficient methods to prevent unauthorized access from other devices.

UltiMaker printers, such as the S series and Factor series, come equipped with built-in firewall capabilities and allow administrators to activate them to ensure that only trusted devices can communicate with the printers.

Zero trust approach

A security philosophy that is widely known and adopted across multiple industries, it refers to the implementation of role-based access control (RBAC) and multi-factor authentication (MFA) for cloud-based management systems.

Through UltiMaker Digital Factory, administrators can assign roles (e.g. admin, member, guest) to users, ensuring that only authorized personnel have access to specific functions. Additionally, the two-factor authentication feature enhances security by adding an extra layer of verification.

As part of our vertically integrated ecosystem, the UltiMaker Cura Enterprise slicer is installed to prevent non-administrator users from accessing the installation of UltiMaker Cura (its basic files or directories). As a result, the “side loading” of plugins is blocked.

Data protection and access control

Now let’s look at how we can safeguard sensitive print files, restrict unauthorized access, and monitor system activity to prevent breaches.

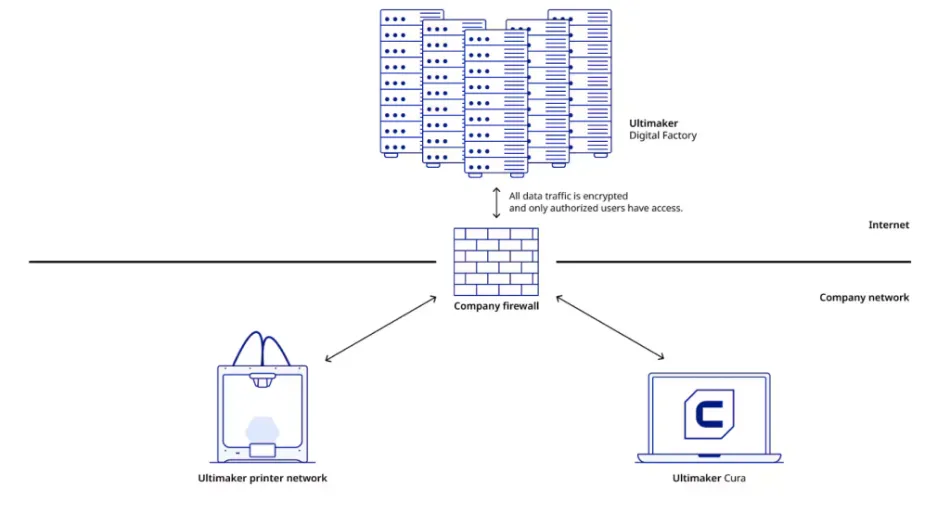

Encrypted communications

Businesses should ensure that print files and G-code are transmitted using encrypted protocols. For UltiMaker, all cloud-based data is transmitted using HTTPS (TLS 1.2) connections with industry-standard 2048-bit RSA encryption, safeguarding data transfer.

User authentication and permissions

Assigning different levels of permissions based on user roles ensures that only authorized individuals can access and control your 3D printers. This helps safely manage print jobs based on assigned roles:

- Administrators: can manage printers, users and workflows.

- Operators: can start and monitor prints but cannot modify critical settings.

- Guests: may have view-only access, ensuring that they cannot interfere with production.

Keep in mind that enabling MFA will help prevent unauthorized logins even if user passwords are compromised.

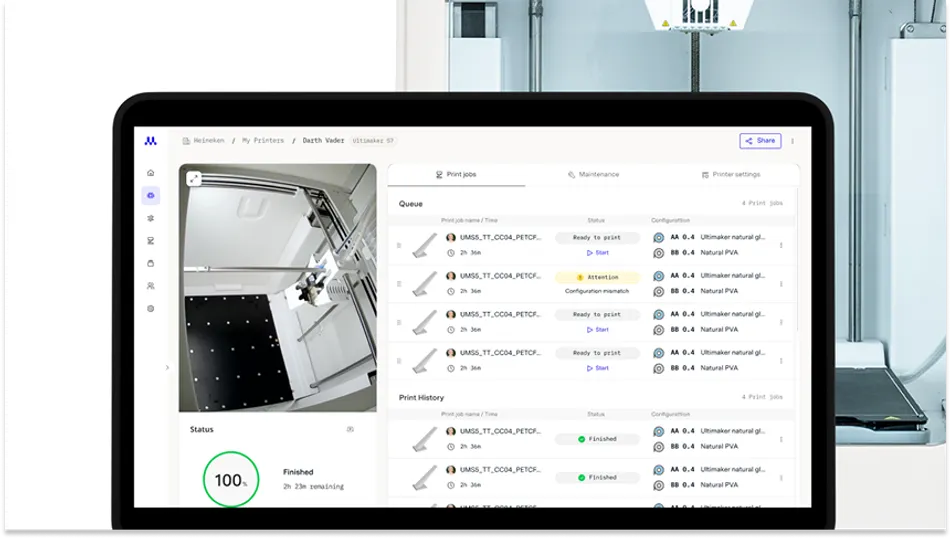

Audit logs and monitoring

Keeping track of who accessed or modified parameters in a 3D printing network is also integral in detecting security breaches. UltiMaker Digital Factory, for example, provides detailed activity logs, allowing administrators to monitor:

- Who started or modified a print job.

- When firmware or software settings were changed.

- Unusual login attempts or unauthorized access.

Audit logs help detect anomalies and enable businesses to respond quickly to potential threats. By implementing real-time monitoring and alters, users can proactively manage security risks in their 3D printing environment.

Software and firmware security

Any system is only as strong as its weakest link.To keep both network and printers protected, users should ensure that firmware and software solutions are always up-to-date.

Regular firmware and software updates

As new vulnerabilities are discovered, frequent firmware updates will ensure that not only will you benefit from the latest features but that you will also receive the newest security patches. Users are always encouraged to keep their devices updated to benefit from the latest protections.

On a similar note, users should always opt for trusted, verified slicing software (such as UltiMaker Cura) to prevent maliciously embedded code and ensure that firmware updates are verified using cryptographic signatures so that only authorized firmware is installed on the printers.

Physical and printer-level security

Securing physical access is just as important as protecting the network and software.

Other than physically restricting printers in a dedicated work area with limited access (e.g. via security badges), an easier and more secure feature is the option to set a PIN-code on each machine to restrict access to the printer settings.

Available on the UltiMaker S series and Factory series printers, this option can be enabled either via the printer’s display or through Digital Factory.

Staying secure with the UltiMaker Ecosystem

We remain committed to supporting open system solutions and allowing our users freedom of choice by never locking out functionality behind mandatory authorizations controls or limiting user autonomy.

We also believe that our vertically integrated ecosystem provides a secure comprehensive solution that is designed for industrial environments.

If you want to stay ahead of cyber threats and keep your 3D printing environment secure, explore UltiMaker’s Digital Factory and our secure ecosystem today to take control of your 3D printing workflow.