Snaptron Streamlines Quality Testing with Efficient Prototyping

Snaptron optimized their quality testing machine, Sapphire, to enable faster data processing and lower costs. Leveraging Arduino’s Portenta H7 Lite, they not only improved in-house quality control but also opened up a new market segment for force-displacement testing solutions.

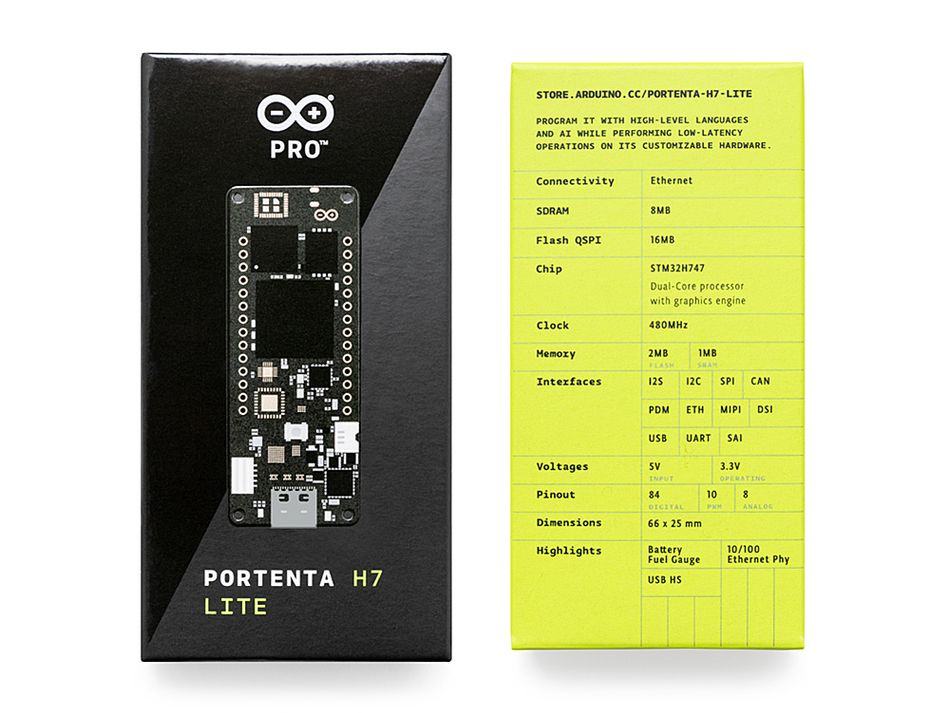

The Arduino Portenta H7 Lite provides an efficient and cost-effective solution for quality testing.

The Challenge: Optimizing Real-Time Quality Testing

Snaptron, a leading manufacturer of tactile dome switches used across industries from aerospace to medical, originally developed the Sapphire Force Testing Machine to ensure rigorous quality control. However, as technology advanced, their Director of Engineering, Kevin Albertsen, recognized the need for an upgrade. Their existing setup, which used stacked PC/104 cards on a single-board computer, was complex and costly, lacking the efficiency needed for real-time data analysis.

Snaptron’s goal was clear: streamline the system to reduce expenses and increase processing speed, providing a high-quality solution without a hefty price tag.

A Simple, Cost-Effective Solution: The Portenta H7 Lite

Snaptron chose the Portenta H7 Lite to upgrade the Sapphire machine. The board’s versatility allowed for rapid prototyping and iteration, reducing development time significantly. With seamless data transfer via USB and straightforward integration of digital and analog connections, Snaptron could simplify in-house PCB assembly and low-volume production.

Albertsen noted the benefit of Arduino’s extensive library support and open-source resources, which accelerated the prototyping phase, freeing up resources for other projects. The Portenta H7 Lite’s cost-effectiveness also helped Snaptron manage their budget, allowing for further improvements to their system.

Expanding Market Opportunities with a New Product Line

What began as an internal solution for quality control quickly revealed market potential. Snaptron discovered that customers also needed a similar force-displacement switch tester, prompting them to develop a commercial product based on the upgraded Sapphire. This new offering has since opened up a fresh revenue stream, showcasing how rapid prototyping can lead to unexpected opportunities.

Curious to find out more? Read the full case study on the Arduino website.