Step into the Center of Future Manufacturing: Experience Intelligent Manufacturing Solutions at Hexagon Live

Learn how manufacturers are leveraging IoT, AI, and automation to tackle global competition, meet sustainability goals, and enhance customization at Hexagon Live on November 27th-28th.

Manufacturers operate in a rapidly evolving environment with a unique set of challenges. Global competition drives them to reduce costs while meeting rising quality expectations. There's also a race to achieve faster time-to-market to attract and retain clients. Meanwhile, government and industry bodies around the globe have been enforcing stringent sustainability mandates. To meet these targets, manufacturers work towards reducing greenhouse emissions and adopt circular economy practices.

On top of this, the pace of technological advancement presents another challenge. Staying competitive requires manufacturers to adopt new technologies, which often comes with high upfront costs and can disrupt established workflows. As teams adjust to new workflow, productivity can temporarily dip, which creates strain.

To overcome these challenges, manufacturers need data-driven strategies to boost accuracy, productivity, and adaptability. Intergrating digital solutions is the way forward as it helps make informed decisions to streamline processes and stay competitive in an every-changing industry.

The Rise of Smart Manufacturing: A Transformation Underway

The fourth industrial revolution, or Industry 4.0, is helping manufacturers integrate digital technologies such as automation, AI, cloud computing, and IoT to create smart factories where machinery, sensors, and software are connected. With real-time data collection and intelligent analytics, companies can detect inefficiencies and make informed decisions to optimize processes.

As a leader in this space, Hexagon offers integrated manufacturing intelligence that spans from design to the final product. By providing tools for design, simulation, and quality management, Hexagon enables manufacturers to adopt processes that drive precision, sustainability, and adaptability.

Did you miss it? Watch Wevolver's reporting from Hexagon Live in Eindhoven on-demandThroughout the event, Wevolver was reporting live on our social media channels from the center of the action on Day 1, which saw an engineering marvel in the form of Max Verstappen’s 2021 championship-winning car, showcased by Oracle Red Bull Racing and the grand opening of Hexagon's brand new 400 square meters Experience Center. |

The Need for Advanced Digital Manufacturing Technologies

Addressing Industry Challenges

Manufacturers face a range of challenges that impact every stage of the production cycle. One of the most pressing is supply chain instability, caused by factors such as natural disasters, trade restrictions, and pandemics. These disruptions can delay production in today's globally distributed supply chains.

Energy and resource efficiency have become critical priorities due to fluctuating energy prices fueled by current geopolitical tensions. High energy costs increase production expenses, trimming already slim margins.

Equipment downtime poses another key efficiency roadblock. Not only does it require costly repairs but also ends up wasting valuable man-hours. The rising demand for customized products adds to these challenges. Manufacturers are now required to frequently perform time-consuming reconfiguration tasks to accommodate a wider variety of designs.

Solving Challenges with Digital Innovation

Digital solutions are addressing core challenges in energy efficiency, downtime reduction, and product customization. While implementing these technologies requires an initial investment, they provide long-term benefits.

To manage high energy costs, manufacturers are adopting IoT-based energy monitoring and automation systems. These systems utilize sensors and smart controls to optimize energy consumption in real time. For instance, occupancy sensors can detect activity in different areas, adjusting lighting and HVAC systems to minimize energy waste.

Predictive maintenance has proven effective in minimizing unplanned equipment downtime. The system leverages historical data analysis, real-time machine health monitoring, and machine learning. When an anomaly or potential failure pattern is identified, the system alerts engineers to perform maintenance before a breakdown occurs.

In response to increasing demand for customized products, manufacturers are turning to digital twins. By creating virtual replicas of production systems, engineers can simulate and test custom designs before production begins, accelerating the design-to-manufacturing cycle. Additionally, companies are deploying flexible manufacturing systems (FMS), which feature modular workstations that can be retooled quickly. This flexibility allows manufacturers to easily switch between different product designs without requiring extensive modifications to the factory setup.

Driving the Manufacturing Intelligence Transformation

Hexagon’s intelligence solutions integrate into the manufacturing ecosystem by seamlessly connecting tools, technologies, and data throughout entire production cycles. At the heart of this integration is the use of advanced tools such as digital twins, automation systems, and simulations. This integration allows data collection from each stage of the process allowing teams to monitor progress more effectively.

Metrology tools help companies ensure that components and products meet exact specifications, maintaining precision throughout production. This minimizes extensive rework and material waste caused by incorrect tolerances. Hexagon enhances this process by providing in-process measurement systems that monitor and measure parts directly on the production line.

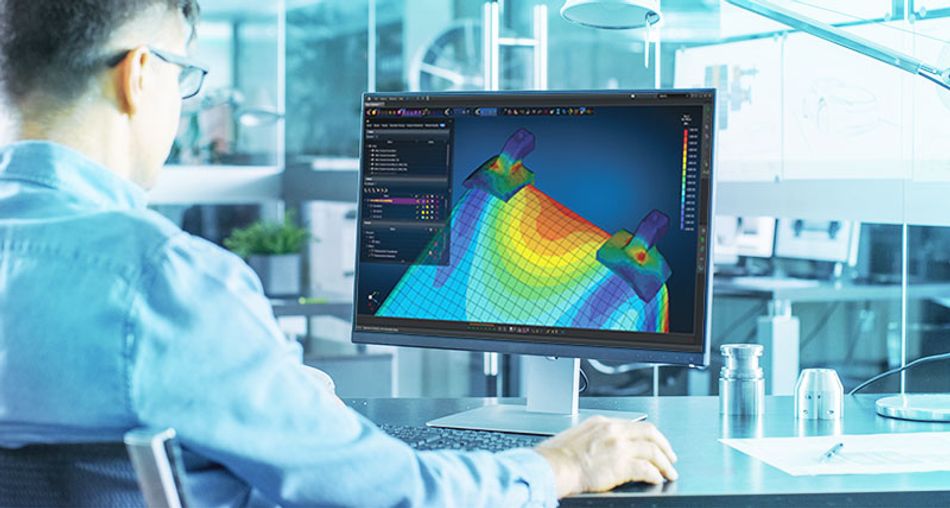

Hexagon's innovative solutions enable real-time collaboration between design and production teams. Through digital simulation, manufacturers can optimize designs before production begins. The ability to check components digitally reduces development time, minimizes material waste, and enhances safety in industries like automotive and electronics.

The company combines automation technologies with its cutting-edge software to optimize manufacturing workflows. By integrating real-time data, it enhances process efficiency and improves operational outcomes.

Its predictive maintenance solutions identify potential issues so that engineers can address problems before they cause costly breakdowns. Such practices ensure smooth operations and extend the lifespan of equipment. Hexagon’s IoT-enabled energy monitoring tools further support sustainability efforts. These tools help companies pinpoint inefficiencies, reduce waste, and optimize resource usage.

Image: Through digital simulation, manufacturers can optimize designs before production begins. Source: Hexagon.

Image: Through digital simulation, manufacturers can optimize designs before production begins. Source: Hexagon.

Support and Success

Hexagon supports some of the world’s leading organizations in various industries. For example, the iconic Red Bull Racing Formula 1 team relies on Hexagon’s metrology equipment and scanners to ensure the precision needed to build their cutting-edge car.

Volkswagen Group’s ŠKODA AUTO also uses Hexagon’s automated measurement systems across its manufacturing facilities to enhance production accuracy and capacity.

Additionally, CERN, the organization dedicated to uncovering the mysteries of the universe, trusts Hexagon’s solutions to monitor its entire technical infrastructure, ensuring seamless operations for groundbreaking research.

For more success stories, click here.

What to Expect at Hexagon Live in Eindhoven: Insights, Innovation, and Networking

Gain Exclusive Knowledge from Manufacturing Experts & Network with Industry Innovators

On November 27th and 28th Hexagon presents participants the chance to engage first-hand with their manufacturing solutions at Hexagon Live. The event also provides an opportunity to build connections with like-minded professionals, opening doors for future collaborations and growth opportunities.By interacting with thought leaders, visitors can gain valuable knowledge that can help them tackle challenges in their businesses.

Content Tailored to Your Needs: Innovation and Problem-Solving

The event offers a range of sessions designed to tackle real-world challenges within the manufacturing sector.

Hear from companies that have successfully navigated manufacturing challenges with the help of digital innovations. These case studies highlight what's possible and serve as a framework for your strategic planning.

Hands-On Exploration of Digital Reality Solutions

The event offers a chance to experience how Hexagon's digital reality tools improve operational efficiency. Visitors get an understanding of how to leverage real-time data, machine learning, and automated workflows to optimize every stage of their operations, from design to delivery.

Explore the Manufacturing of Tomorrow at The Experience Center

Hexagon's new Experience Centre in Eindhoven brings the future of manufacturing to life, offering visitors a chance to see how cutting-edge technologies are reshaping the industry. Being one of the first of its kind in Europe, the center promises an immersive experience where you can explore emerging trends, solutions, and new products first-hand. From reimagining production lines to real-time energy monitoring, the center showcases how facilities are evolving to meet the demands of next-generation aircraft and electric vehicles.

“It’s about creating a memorable “wow” factor, leaving visitors inspired by a company offering robust solutions to today’s challenges and a visionary partnership for the future. Experience Centres have the potential to be game-changers.”

Marcel Brand, Senior Director Global Events & Experience Centres

Hexagon, Manufacturing Intelligence division

In addition to theory, attendees can get hands-on with the PRESTO system and discover how automation is transforming quality control by improving precision and drastically reducing inspection times.

Explore the HxGN Machine Trainer, a digital twin simulator used by industry leaders like Safran to train CAM programmers and machine tool operators quickly and safely. Visitors can also experience CMM machines and 3D scanners up close, gaining insights into the latest technologies driving innovation in aerospace, automotive, and electronics manufacturing.

Hexagon Live Day 1: 27 November – Strategic Insights

Practical Innovation Workshops

The workshops at the event are designed to address challenges in managing complex semiconductor supply chains. Experts will help attendees understand how to streamline operations to manage global disruptions and enhance supply chain resilience to ensure material availability.

Visitors can discover how to utilize data and automation to optimize processes in the energy industry. From increasing efficiency to reducing waste, these strategies can improve operations at every level.

The event touches also upon the latest technologies in energy production and distribution, with a focus on how AI and machine learning are helping in energy forecasting and demand management. You'll learn practical approaches for integrating renewable energy sources into existing infrastructure.

Insightful panel discussions

The company will also host panel discussions featuring industry leaders and experts who will share their perspectives on industry advancements.

These discussions will explore how technologies digital twins and simulation are accelerating design and product development cycles in both aerospace and automotive manufacturing.

An F1 Engineering Marvel Up Close

Who better to offer insights on staying ahead of the competition than Oracle Red Bull Racing? This legendary team has secured 6 Constructors' Championships and 7 Drivers' Championships.

Competing against the best in the world leaves Red Bull Racing with no margin for error. Don’t miss Red Bull’s keynote to learn how Hexagon helps the team achieve unparalleled accuracy, efficiency, and speed in a sport where just one-tenth of a second can make all the difference.

Hexagon Live Day 2: 28 November – Technology Deep-Dive

In-Depth Exploration of Technical Breakthroughs

On the second day of the event, attendees will get to discover the latest metrology solutions, including in-process measurement that integrates metrology directly into the production phase. The session will also cover the impact of these innovations on quality control processes.

Next, visitors can explore finite element analysis (FEA) simulation techniques, which utilize digital models to simulate how objects behave under forces to predict real-world results. It will be followed by a deep dive into advanced design, feasibility, and cost optimization for sheet metal components.

Gain Innovative Perspectives

The event will highlight how non-contact reality capture offers real-world analysis with precise 3D representations of environments. Attendees will learn how this technology enables engineers, builders, and forensic teams to ensure no critical details are overlooked. With edge computing, they can validate data accuracy directly on-site, streamlining the process and improving outcomes.

Ready to Be a Part of the Future?

Hexagon Live offers a unique opportunity to explore the latest in manufacturing innovation and gain valuable insights to stay ahead in this ever-changing industry.

Discover advanced solutions like automation and digital twins, designed to boost efficiency and improve quality. Attend discussion panels and workshops to connect with leading professionals and gather expert knowledge.

Best of all, general admission is completely free. What are you waiting for? Use the following links to reserve your spot today!

Unable to attend? Wevolver livestreamed the event on our Linkedin and Twitter.