Strengthening Supply Chains: The Power of Domestic Sourcing

Manufacturing sourcing within North America shortens lead times, reduces geopolitical and transportation risks, and enhances supply chain efficiency and resilience.

Introduction

Recent events such as pandemics, geopolitical conflicts, and natural disasters have exposed the unpredictability of global supply chains within manufacturing. Changes in global trade policy, including tariffs and varying regulatory compliance across countries add to the uncertainty. Long lead times further complicate international sourcing of engineered parts, while financial uncertainties such as fluctuating currency exchange rates and unpredictable transportation costs add another layer of complexity.

One way for manufacturers to address these challenges is by sourcing industrial suppliers locally. Working with domestic suppliers reduces transit times, leading to faster deliveries. Shorter shipping distances reduce transportation expenses and help businesses cut their carbon footprint. Many American companies can simplify regulatory compliance by sourcing within North America. Prioritizing local suppliers helps protect US businesses from international trade disruptions. This approach improves supply chain efficiency and resilience.

Overcoming Global Sourcing Issues with Local Procurement

Challenges of overseas sourcing

Long lead times

Businesses usually source from overseas suppliers to leverage lower labor costs. However, this approach comes with significant challenges. One of the biggest issues in international sourcing for manufacturing companies is long lead times. Shipping goods across continents can take weeks or even months, causing delays that disrupt production schedules[1]. If not carefully managed, these delays can lead to operational setbacks and missed deadlines. Long lead times also tie up capital in inventory, which increases the holding costs for businesses.

High transportation costs

Another challenge is the rising cost of international shipping[2]. Geopolitical tensions and increasing fuel prices have made global shipping rates highly volatile[3]. Recent events, like the Red Sea shipping crisis, have only worsened things. Cargo and tankers passing through this region had to take longer routes by up to 53 percent, which led to higher shipping costs and increased CO2 emissions[4].

Compliance Issues

Another crucial challenge is regulatory compliance. Each country has its own rules and standards regarding product safety, environmental regulations, intellectual property protection, and ethical compliance. Failing to comply may result in fines, shipment rejections, product recalls, and reputational damage[5]. To ensure legal requirements are met, businesses may need to hire compliance experts or work with third-party partners.

The strategic advantages of local sourcing

Faster lead times

One significant advantage of local sourcing is the reduction in lead times. When sourced from local suppliers, transportation times are reduced from weeks or months to just a few days. This faster turnaround helps keep production schedules on track and allows companies to respond quickly to customer demands.

Lower transportation costs

Shipping over shorter distances not only reduces transportation costs but also eliminates additional expenses such as customs duties, port fees, and handling charges. Local sourcing also allows businesses to adopt lean, just-in-time (JIT) inventory practices[6]. For companies ordering in large quantities, these savings can be substantial.

Easier compliance with US regulations

Working with local suppliers that fully understand domestic regulations helps businesses reduce the risk of non-compliance. It also makes on-site supplier inspections easier for labor and ethical sourcing practices. Local suppliers can also quickly adapt to regulatory changes, which is crucial in industries such as automotive, food, and pharmaceuticals, where non-compliance can lead to costly recalls and legal penalties.

Better security

Local sourcing offers tighter control over the supply chain. When goods are sourced within the US, they are less likely to be affected by geopolitical tensions, shipping delays, and port congestion. Patents granted in the U.S. are only valid within its borders and have no effect in other countries[7]. This makes working with overseas manufacturers riskier, as some may reverse engineer proprietary designs and sell similar products in other markets. On the other hand, local suppliers operate under strict intellectual property laws, making it easier to enforce protections and prevent counterfeiting.

Benefits of Local Sourcing in North America

Working with US-based manufacturers helps boost the local economy. It helps keep investments within the country and creates new jobs. Another advantage is the ability to respond quickly to changing market demands. Faster turnaround times make it easier for companies to refine their products and keep up with the latest trends. Dealing with local manufacturers also simplifies communication and coordination, a common challenge when working with overseas suppliers.

By partnering with domestic manufacturers, companies can cut down on emissions caused by transportation[8]. Additionally, U.S.-based manufacturers adhere to strict environmental regulations, which ensure responsible waste management.

Sourcing locally also ensures fair wages, workplace safety, and ethical treatment. In contrast, sourcing from countries with lower labor costs may unknowingly support labor exploitation. A well-known example is the controversy surrounding Apple, where the tech company's suppliers were linked to forced labor in China’s Xinjiang region[9].

Reshoring Made Simple with Thomasnet

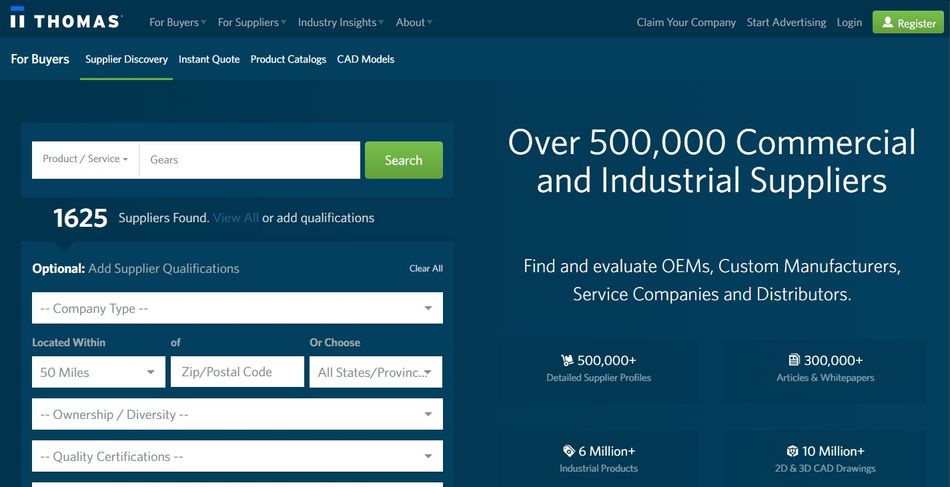

Thomasnet.com is a leading sourcing platform that helps buyers, engineers, and MRO professionals connect with manufacturers across North America. Whether you need materials, components or to streamline your sourcing process, Thomasnet provides the tools and resources to assist you in making an informed decision. With a legacy spanning over 125 years and more than 1.4 million registered professionals, Thomasnet remains a go-to platform for industry leaders.

Thomasnet offers a range of features that make it easier for businesses to connect with reliable US-based suppliers. Its extensive supplier directory includes over 500,000 manufacturers across North America. Each listing includes detailed company profiles, product categories, and certifications. Additionally, Thomasnet provides in-depth supplier capabilities, including information on manufacturing processes, industries served, and compliance with industry standards.

The platform simplifies sourcing with tools like the RFQ (Request for Quote), which lets buyers quickly request pricing and availability. Instead of contacting multiple suppliers individually, you can shortlist two or more and send quote requests with a single click. The platform also offers advanced search filters, allowing users to find companies within 10 to 1,000 miles of their zip code. Buyers can filter by certifications such as AISC, ISO, and SQF. For companies looking to reshore, these custom search and filtering options make it easy to find the right domestic suppliers.

Leveraging Thomasnet for Enhanced Local Sourcing

Follow this quick guide to locate and evaluate suppliers in the U.S. that fit your criteria:

1. Navigate to the Supplier Discovery page: https://www.thomasnet.com/suppliers/

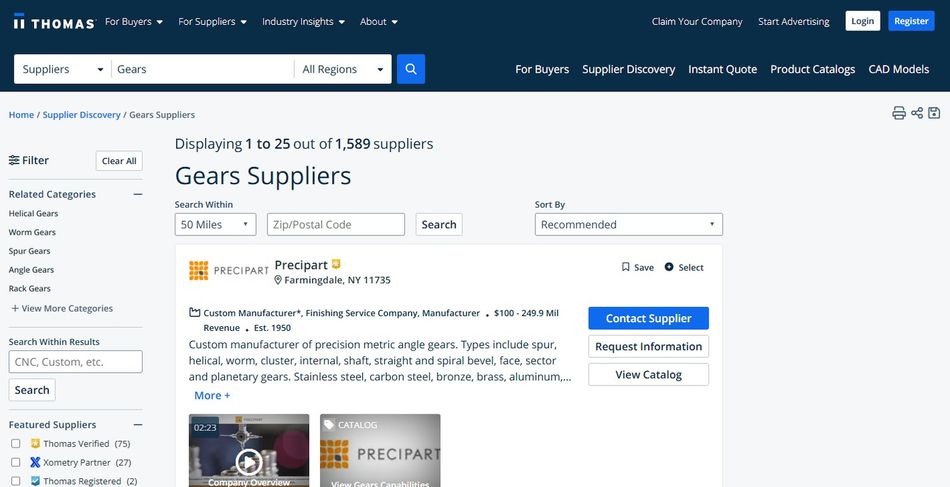

2. Enter the raw material, service, or component you wish to source. For this demonstration, we are going with "gears."

3. The website provides a list of gear suppliers. In this case, we found over 1,500 suppliers.

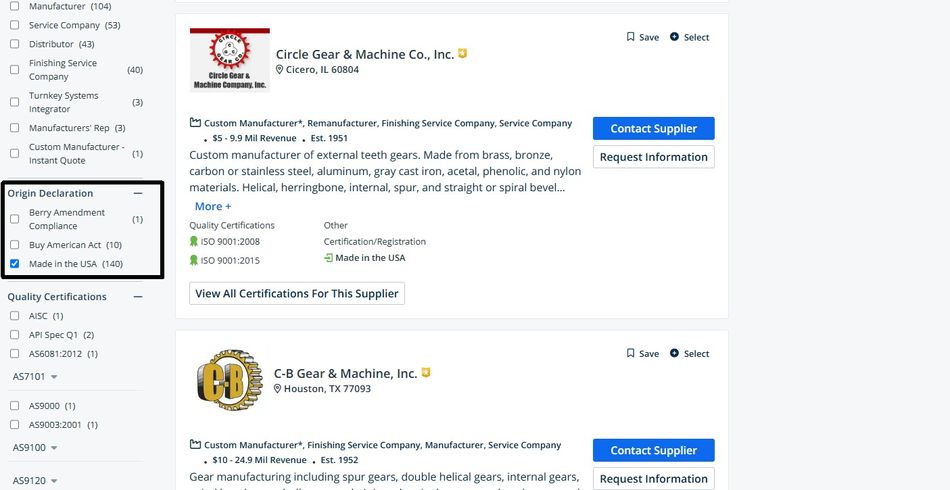

4. Scroll down until you see the "Origin Declaration" filter on the left-hand side. Depending on availability, you'll see options such as Made in the USA, Buy American Act, and Berry Amendment Compliance. We are selecting Made in the USA to narrow down the options.

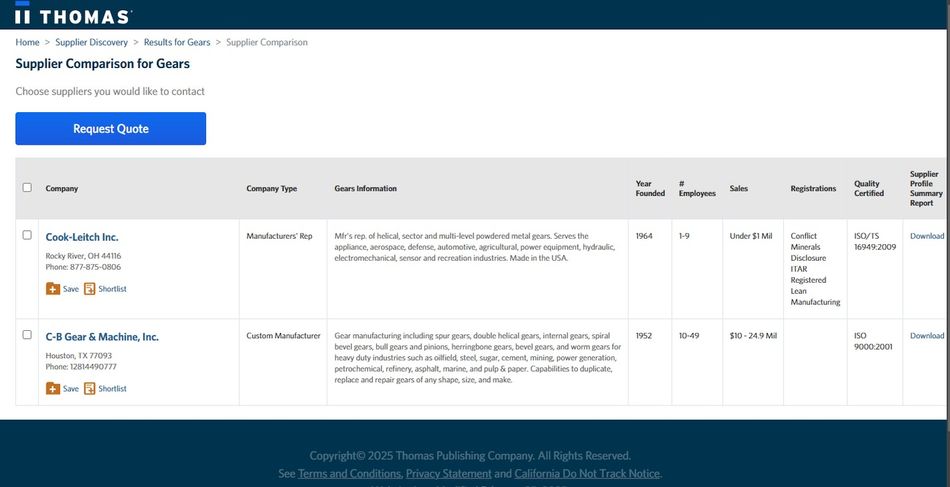

5. Shortlist the suppliers that fit your needs by clicking on "Select." If you shortlist multiple suppliers, the website provides an option to compare them. You can also save your shortlist and revisit it later for easy access and decision-making.

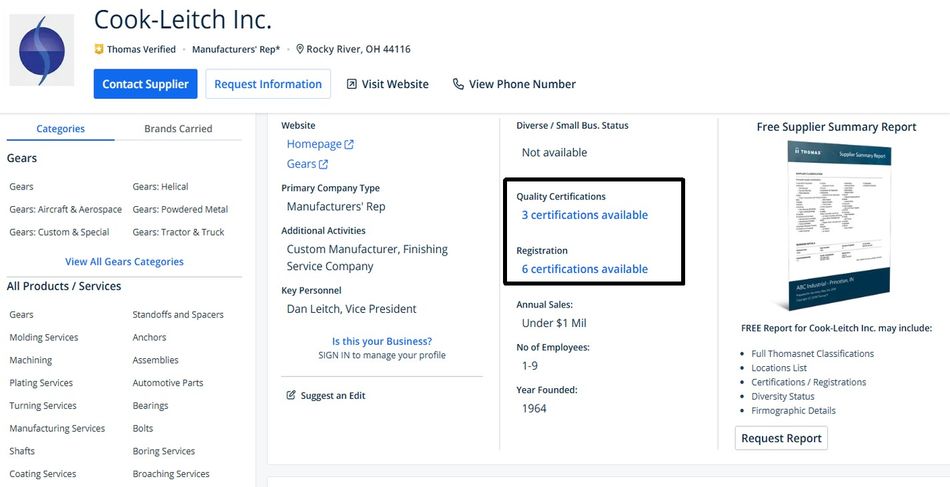

6. Before finalizing, open the supplier's profile and scroll down to the Quality Certifications and Registration section to review its documents. If a certain document is missing, you can request the supplier to provide it.

| QUICK GLOSSARY | Made in the USA lABEL: Companies with this label produce one or more products in the United States. Buy American Act (BAA): This federal law limits the purchase of foreign goods for U.S. government contracts. To comply, businesses must ensure that the cost of domestic materials in their end product exceeds that of non-domestic materials. Berry Amendment: This regulation requires the Department of Defense to purchase only US-made goods to support domestic industries. Compliance means all components must be 100% sourced and manufactured in the U.S. |

Summary

Local procurement is more than just a strategy for reducing lead times and costs. It strengthens supply chains, supports the economy, and promotes ethical and sustainable business practices. By working with US-based suppliers, companies can mitigate risks associated with global disruptions and ensure compliance with domestic regulations.

Thomasnet makes this process easier by connecting businesses with an extensive network of suppliers across North America. Its elaborate search tools and filters make it easy to find reliable partners that meet your specific needs.

Register on Thomasnet today to take the next step toward a more resilient supply chain.

References

1. https://www.wtagroup.com/resources-and-insights/blogs/how-long-does-sea-freight-take

2. https://www.dw.com/en/rising-shipping-costs-hit-global-trade-hard/a-69586965

3. https://www.statista.com/statistics/1440707/global-container-freight-index/

4. https://blogs.worldbank.org/en/developmenttalk/navigating-troubled-waters--the-red-sea-shipping-crisis-and-its-

5. https://www.stibosystems.com/blog/supplier-compliance

6. https://www.violintec.com/contract-manufacturers/what-is-just-in-time-manufacturing-why-is-it-important/

7. https://www.uspto.gov/ip-policy/ipr-toolkits

8. https://www.maersk.com/insights/growth/2024/06/03/the-importance-of-local-and-strategic-sourcing

9. https://www.techtransparencyproject.org/articles/apple-faces-new-us-law-targeting-uyghur-forced-labor