Submerged Arc Welding (SAW) Explained

Submerged arc welding is a standard industrial process wherein an arc is formed between a workpiece and an electrode. It was invented in 1935 by the E. O. Paton Electric Welding Institute in Kyiv, Ukraine as a driving force behind the Second World War. One of the most notable applications of this invention is the T34 military tank.

This article was first published on

fractory.comSubmerged arc welding is a standard industrial process wherein an arc is formed between a workpiece and an electrode. It was invented in 1935 by the E. O. Paton Electric Welding Institute in Kyiv, Ukraine as a driving force behind the Second World War. One of the most notable applications of this invention is the T34 military tank.

While this welding technology has been around for almost a century, it is still an essential choice for many industries.

What Is Submerged Arc Welding?

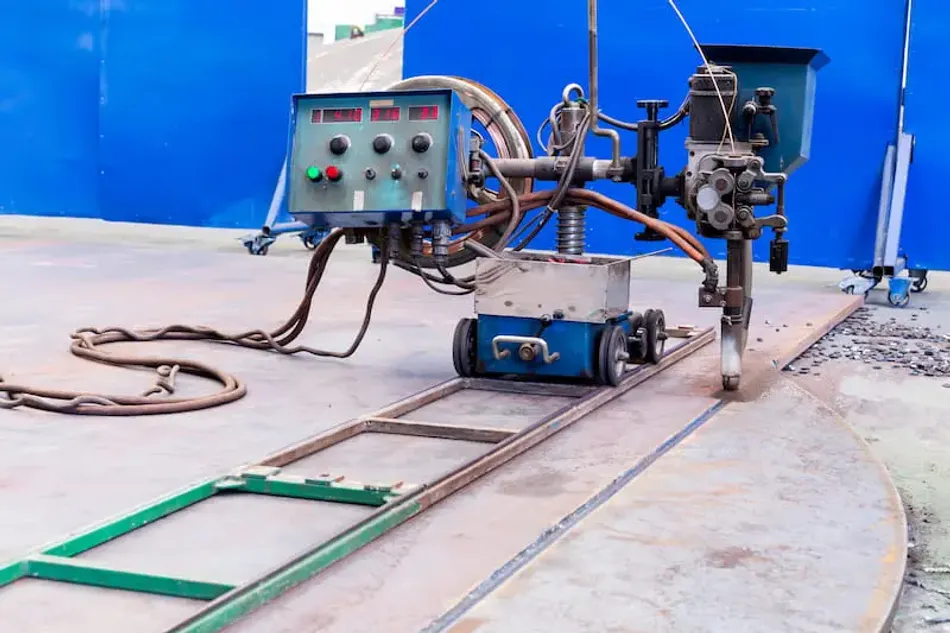

Submerged arc welding (SAW) is a welding method where similarly to other arc welding processes, the base metals are joined by forming an electric arc between the workpiece and an electrode.

SAW process’s defining element is how it protects the weld metal from atmospheric contamination. Submerged arc welding uses a powdered flux layer, generating shielding and slag while creating a smooth and clean weld. Other methods use shielding gas (MIG/TIG welding), flux-cored wire (FCAW), flux-coated electrode (SMAW), or controlled environment (plasma welding) for protecting the weld.

How Does the Submerged Arc Welding Process Work?

Submerged arc welding creates consistent welds by using a blanket of granulated flux. For this reason, the process can be operated only on positions that are flat and horizontal, with the weld advancing by either moving the welding system or the workpiece.

Flux is fed into the joint manually or by using a flux hopper. A single electrode or multiple wire electrode system is placed into the working area, surrounded by the flux blanket. Parameters such as the welding current, arc voltage, and wire feed speed are set depending on the type of metal, its thickness, and desired mechanical properties. Electric current is supplied to the electrodes, producing intense heat that melts and fuses the base material and the filler wire to the bead.

The molten metal cools down, creating strong uniform welds and reusable granular flux at the surface and slag underneath. A hopper collects the reusable flux, while slag is usually peeled off manually.

SAW produces high-quality welds with fewer weld defects than other processes. However, this does not mean that defects won’t ever occur. When they do, it’s generally related to wrongly set welding parameters.

Flux

Granular Flux

Granular flux inside a hopper is usually composed of oxides from aluminium, calcium, magnesium, manganese, silicon, titanium, and zirconium. This composition suits the type of electrode to achieve the metal’s desired properties as it chemically reacts as it melts.

Bonded Flux

Bonded flux is produced by drying the composition and slowly baking it, usually with a compound such as sodium silicate. As an advantage, bonded flux can contain alloying elements, offering flexibility for some applications and protection against rust.

Fused Flux

Fused flux is produced by melting the composition inside an electric furnace. The molten flux is formed into homogenous particles as it solidifies. It is excellent for creating consistent welds along the bead.

Wire Electrode

SAW uses a wire spool to feed the wire electrode into the weld. The wire’s thickness is usually between 1.6mm and 6mm. Electrodes may come in the form of solid, twisted, or cored wire and may be operated using different power sources.

Specific circumstances may need the use of modified wire electrodes and electrode systems to achieve the desired weld profile:

Twin-wire

Multiple wires

Single wire with hot/cold addition

Metal powder additive

Tubular wire

Multiple wire systems typically use a lead wire to improve penetration, while a trailing wire is used to add extra fill and improve the bead profile. Additional wires are used in the electrode system to add more deposition to the weld pool.

Materials

Submerged arc welding process is used with the following materials:

Copper alloys

Low to medium-carbon steels

Low-alloy steels

Mild steels

Nickel-based alloys

Stainless steels

Uranium alloys

Power Source

Submerged arc welding can operate on multiple power outputs, allowing it to manipulate the weld results. Multiple electrode systems enable SAW to run wires at different power sources, to better control the bead profile and penetration.

DCEP offers the most stability and penetration, while DCEN is optimal in increasing deposition rates. Running this welding process in AC is the middle ground where a balance between the two is achieved.

Applications and Industries

Fabrication

SAW is one of the preferred welding processes in fabricating pressure vessels, pipes, and boilers due to its strength in longitudinal and circumferential welding. This welding operation achieves a smooth weld pool from the continuously fed electrode.

Shipbuilding

The flexibility of SAW process allows it to be performed both indoors and outdoors which makes it suitable for shipbuilding. It’s perfect for creating long, straight welds for heavy metals which make up ship parts.

Automotive

Metals used in the automotive and military industry are fit for SAW, along with the speed and efficiency it brings. This welding method is also perfect for automation, with the option to have multiple or single-pass welds based on the metal’s thickness.

Railways

The submerged arc process allows deep weld penetration, which is attractive to the railway industry.

Advantages of SAW

The blanket of granular flux creates minimal welding fume and spatter.

Allows performing semiautomatic or fully automatic welding.

Flexible for both indoor and outdoor applications.

Creates smooth, uniform and deep welds.

Around 50-90% of the flux is reusable and recyclable.

Limitations of SAW

Limited to flat and horizontal welding positions

A rather narrow range of weldable metals.

Requires post-welding slag removal.

Practically restricted to circumferential and long straight beads.

Precise parameters are required to achieve desired weld deposit since welds aren’t visible while welding.