The cloud is disrupting manufacturing and its only just the beginning

The cloud accelerates innovation by enabling reducing the need for investment through pay-as-you-go models and increasing collaborative design opportunities.

Image: ABB

Introduction

The cloud revolution in the computer industry started small - a way to store the billions of photos and videos that smartphones suddenly allowed us to take. It then edged into larger scale data storage and now impacts so much of our daily tasks and use of services from shared files to commands to Alexa.

Data centers are dead.

In a blog post titled 'The Data Center is Dead', Gartner Research VP Dave Cappuccio suggests that 80 percent of companies will have shut down their traditional data centers by 2025. Cloud services, the IoT, and other innovations mean the traditional on-premises data center will have limited advantages in the future, the analyst firm explained. This is part of an evolutionary shift in the way business delivers services to customers driven by the increasing ability of cloud computing.

How the cloud changed business

The advent of the cloud has changed business forever and is now at the core of almost all business infrastructure. Arguably where the cloud has had the biggest impact is in the massive costs it has allowed businesses to cut. The ability to pay as you go for services from data storage to software meant any business could have the best with no upfront investment allowing startups and scaleups to thrive.

Similarly, cloud service providers offer responsive constant service and consultancy - meaning companies can avoid being left behind by out-of-date IT teams. Bulky, inefficient IT departments and costly consultants are no longer required for businesses to stay in pace with innovation. In fact, the increasingly competitive market of cloud service providers gives customers leverage to demand responsive support and advice. Finally, the cloud cuts the headache of implementing, understanding and supporting new layers of integration, customization, and configuration of internal data infrastructure. Combined the cloud provides a level of agility to businesses that was previously only accessible with the privilege of investment. Now armed with an idea and a credit card a business can be born in minutes – using exactly the same services as a multi-national competitor, completely revolutionizing the business world.

Manufacturing with the cloud accelerates innovation.

Soon to be Amazon CEO, Andy Jassy was correct in predicting the cloud revolution in the above quote, however, manufacturing is not going to be left behind. What looked impossible when Jassy spoke in July 2019 now feasible. The cloud helps manufacturers transform processes to improve business operations in similar ways to non-manufacturing companies and even goes further, driving innovation in an industry that can be notorious for slow change. Through a sharing of global manufacturing resources, cloud manufacturing reduces time-to-market, improves quality of service, as well as reduces manufacturing costs - it achieves this through a series of important ways.

End of Request for quote

One of biggest contributors the cloud has made to manufacturing so far is the slaying of the request for quote process. Previously customers who required manufacturing services would need to engage in a request for quote process with each individual supplier, negotiating the terms of each offer. The use of the cloud delivers a method of full pricing transparency from a single portal. One example of this is the 'hourly model' where a cloud-based platform uses AI-based software to analyze your request for manufacturing services and finds the best manufacturing solution for you by collating data from a huge suite of service providers. An hourly rate for the services required is then negotiated based on expected future demand, process type, and complexity. This example of cloud manufacturing uses data-driven decisions and resource management to radically improve parts and components' delivery.

Product design improvement

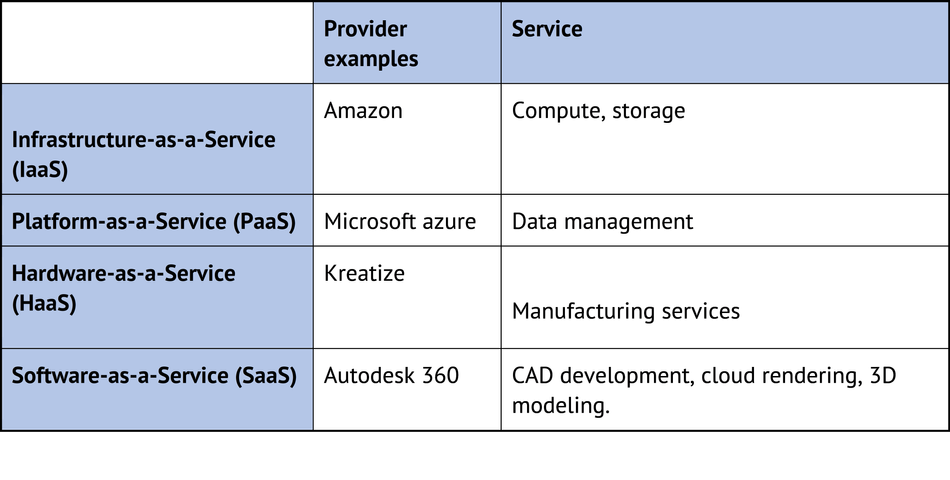

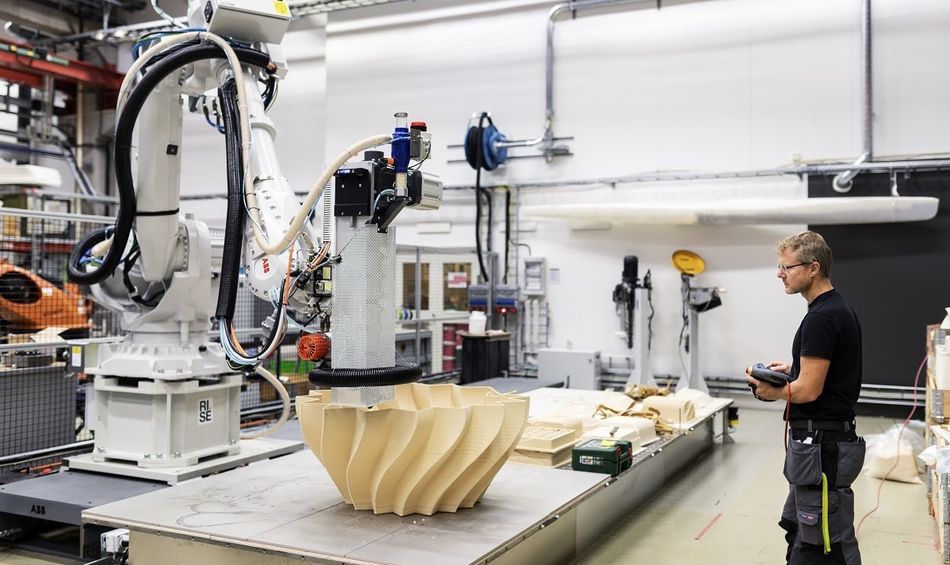

Cloud-based design and manufacturing, known as CBDM, is a rapidly growing service-oriented networked product development model in which service consumers can configure products or services through the use of "as-a-service" sectors, including Infrastructure-as-a-Service, Platform-as-a-Service, Hardware-as-a-Service, and Software-as-a-Service. For example, General Electric (GE) and the Massachusetts Institute of Technology (MIT) are jointly developing a platform to support the ongoing adaptive vehicle portfolio of the Defense Advanced Research Projects Agency (DARPA) (2013). The crowdsourcing platform will allow a global community of designers to contribute to design and rapidly manufacture complex industrial systems such as aviation systems and medical devices by connecting data, design tools, and simulations in a distributed and collaborative setting. Complex models, simulations, and even physical products by way of 3D printing can be shared effortlessly and rendered both through collective effort as well as collective computing. Teams can solve compute-intensive problems and improve the pace of innovation from anywhere.

Physical products can be shared by 3D printing through collective computing for remote team prototyping.

Physical products can be shared by 3D printing through collective computing for remote team prototyping. Scalability

If 2020 taught us anything, it's that you don't need to be in the same room as someone to work effectively on a project. The increasing ability of CBDM platforms delivers truly remote, global business at any scale. The previous idea that businesses needed first a headquarters and then a manufacturing facility has been made obsolete. Businesses can seize the opportunity to increase in scale, product diversity, and global position without upfront debilitating investment. This has shortened product cycles and shrunk the time to market. Experiments with software, materials, services, and ideas happen on a pay-as-you-go basis until the right combination of elements comes together.

Improved security

Manufacturers and product developers must manage a significant amount of sensitive data every day. This includes the engineering specifications for specific projects, but also tests data, warranty records, and device service records – all of which may be highly confidential. Leading cloud manufacturing service providers provide 256-bit encryption on all files as well as other data protection methods.

The way Cloud Manufacturing is delivered

As previously described, cloud manufacturing comes together as a series of services that enable businesses to build a flexible, low-cost model that emphasizes agility, innovation, and best practice resource management. Depending on a business type, the combination of providers they engage in will expand and contract as the business evolves and scales – again highlighting the impact low-investment, pay-as-you-go models in manufacturing can make.

Kreatize is the first company to have developed the hourly model for cloud manufacturing onto their platform. From their digital platform, customers and manufacturing partners can easily handle the complete process from ordering to delivery of their custom parts. Customers can order a part directly online with just a few clicks or request a quote and have full transparency of their order at all times.

Conclusion

The cloud is already here for manufacturing, proving its value and growing fast. The growth of the cloud in manufacturing can be expected to follow the same exponential curve as the computing cloud. Its speed is currently staggering, and I am sure Andy Jassy is already rethinking his predictions less than two years after making them.

References:

Wu, Dazhong & Rosen, David & Schaefer, Dirk. (2014). Cloud-Based Design and Manufacturing: Status and Promise. 10.1007/978-3-319-07398-9_1.

Transform your manufacturing operations with AWS Cloud [Internet]. Amazon Web Services, Inc. [cited 31 March 2021]. Available from: https://aws.amazon.com/manufacturing/