The future of rail transport - Technologies for tomorrow

The German Aerospace Center (DLR) is researching the infrastructure and railway operational framework conditions, working on new, capacity-increasing concepts for vehicles, operations and infrastructure, as well as innovative methods for maintenance and servicing.

NGT CARGO in the wind tunnel. Credit: DLR (CC BY-NC-ND 3.0)

State-of-the-art, affordable, climate and environment-friendly rail transport plays a central role in the mobility transition. Only an attractive offer will bring more people and goods onto the railways. To make this possible, the German Aerospace Center (Deutsches Zentrum für Luft- und Raumfahrt; DLR) is researching the infrastructure and railway operational framework conditions, working on new, capacity-increasing concepts for vehicles, operations and infrastructure, as well as innovative methods for maintenance and servicing. Strategies for automated rail traffic are also among the focal points, as is work on the future role of dispatchers and train drivers in rail traffic control and monitoring. DLR will provide an insight into its current work, projects and results at the InnoTrans trade fair for transport technology from 20 to 23 September 2022 in Berlin (Hall 2.2, Stand 460).

"The importance of the rail system is currently becoming more clear than ever. The 9-Euro-Ticket has been significant for both the potential and the challenges of passenger transport. The low water levels of the rivers have restricted inland waterway transport and have also shown that railway capacities must not be neglected. DLR is conducting research on the entire rail system in order to increase rail capacities as well as comfort, safety, reliability and punctuality. Through transfer from research to rail," says Karsten Lemmer, DLR Executive Board Member responsible for Innovation, Transfer and Research Infrastructure.

DLR is the largest institutionally funded research facility in Europe with regard to rail transport research. A total of 13 DLR institutes contribute to research, development and the transfer of innovations for rail transport. As a founding member of the Horizon Europe partnership EU-Rail, DLR works together with European rail operators and industry to further develop the railway system.

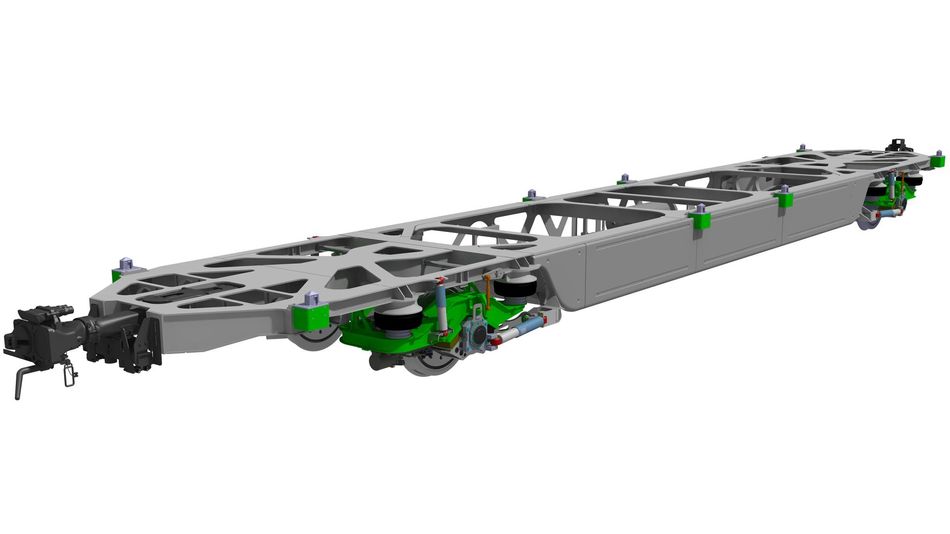

Premiere at InnoTrans 2022 – High-tech running gear for the train of the future

The running gear of a train plays an important role in fast, reliable, safe and comfortable rail transport. This is why DLR is working on a novel, future-oriented chassis design as part of the Next Generation Train (NGT) flagship concept: it dispenses with continuous wheel axles, each wheel is driven independently and controlled intelligently.

The advantages of this approach are that trains could be more efficient and quieter in the future, with less wear and tear on wheels and rails. The structure and materials used in this high-tech chassis are optimised to be as light as possible, both in the load-bearing components and in the drive motors. Less weight reduces energy consumption and allows a greater payload. New degrees of freedom are also offered in the construction and design of the car's interior because the spatial restrictions imposed by wheel axles are eliminated.

The concept has already proven promising in simulations and experiments with a one-to-five scale model of the NGT chassis. Therefore, the DLR researchers have now built a functional model as well as a full-scale test rig. With the help of this research infrastructure, called NGT FuN, the technology will be further developed and demonstrated over the next few years. DLR is presenting the chassis and research infrastructure for the first time at InnoTrans.

Stable and fast on the move – even in crosswinds

With its Crosswind Test Facility in Göttingen, DLR has at its disposal a research infrastructure that is unique in the world for investigating the effects of crosswinds and gusts on moving trains. At InnoTrans, DLR will be demonstrating exactly how this facility and especially the gust generator work with a model-scale exhibit. This large-scale facility can be used to further improve the aerodynamics of rail vehicles and thus ensure safe and at the same time energy-efficient operation. This is because vehicles are also becoming lighter and lighter in the rail sector thanks to innovative lightweight construction concepts and new types of materials. This poses new challenges for the aerodynamics and stability of these vehicles.

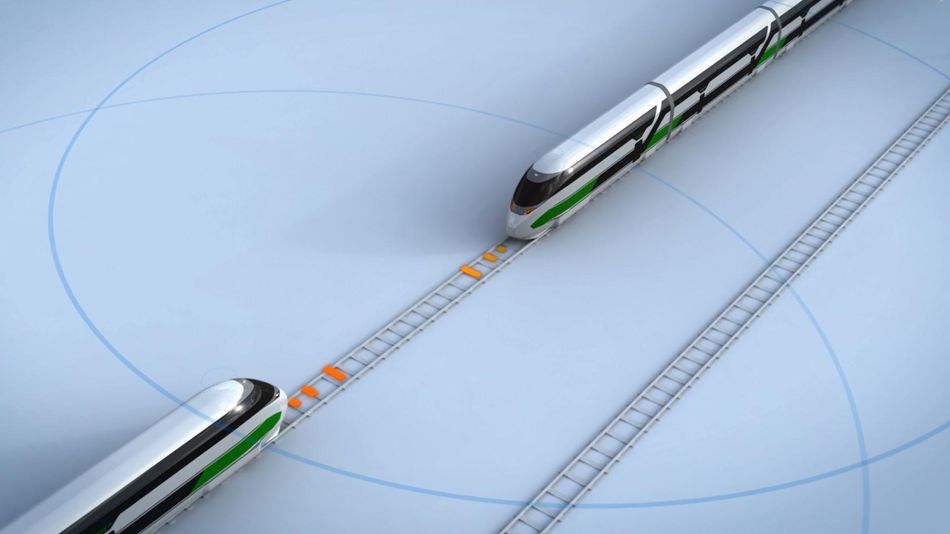

Rethinking previous technology – Slip coaching and dynamic coupling

Dynamically coupled train cars do not require a mechanical connection between the individual multiple unit trains. Dynamic coupling is an operational innovation of DLR's Next Generation Train (NGT) concept. With this function, it is possible to virtually couple trains and thereby increase or decrease train formations during the journey. This also enables a new type of operating concept, the model for which is the historical 'slip coaching'. In the future slip coaching procedure, several train sections run dynamically coupled between nodal stations. Only individual train sections stop at intermediate stations, while the main train can run through at full speed. This new concept could help to implement an improved service with higher frequency, reduced travel times and additional direct connections using existing infrastructure. To demonstrate these advantages, the researchers have constructed an interactive online demonstrator that InnoTrans visitors can try out at the DLR stand.

Digital rail - teleoperation of trains, sensor data for more efficient maintenance and dynamic seat reservation

In the area of digitalisation of rail operations, DLR will be providing an insight into its research work on driverless trains at InnoTrans 2022. In the future, 'remote train operators' could monitor trains from a control centre, intervene in the event of disruptions or control them remotely if the highly automated train is no longer able to move forward.

The basic prerequisite for the use of such systems in rail transport is absolute reliability. This can only be guaranteed by independent verification. In the RailSiTe® railway laboratory, DLR has been researching new concepts and procedures for around 10 years in order to bring complex safety systems for rail transport into operation more quickly. Regular reports of delays in operations due to faults in signalling technology or during the introduction of the 'European Train Control System' (ETCS) safety system demonstrate the relevance of this topic and the need for new test methods. DLR's long experience ensures, for example, that complex tests, which used to take one year, can be completed in two months.

Other exhibits show demonstrators, projects and results for testing digital safety technology and embedded condition monitoring of track infrastructure. With digital test systems, systems can already be efficiently tested and qualified for use by manufacturers today. With sensors in the infrastructure and on trains, information about the condition of points, interlockings and rails could be obtained quickly and reliably. In this context, DLR is also working on machine learning and artificial intelligence methods to evaluate this information as efficiently as possible. In addition, it is developing diagnostic models to support those responsible for facilities and infrastructure in their decisions on maintenance and repair work.

Under the heading 'dynamic seat reservation', DLR is presenting a new approach to the problem of how train passengers could avoid unnecessary journeys through the train cars: namely by changing their seat reservation in real time as soon as they have located a free and not yet reserved seat. This would limit the flow of passengers in the carriages, significantly shorten boarding times and improve the travel experience.

Technology upgrade for freight car concept

On the Open Air Area South at InnoTrans (Stand T04/17), DLR will be showcasing its research work for a cutting-edge future goods freight car – and thus full-scale hardware. The prototype was developed as part of the FR8RAIL IV project of the European rail initiative Shift2Rail together with European project participants from research and industry. It has two wheel axles, no bogie, is height-adjustable and can be coupled digitally and automatically. A special lightweight steel construction was used for the design. The structure of the wagon is topology-optimised. This means that the use and distribution of materials follow predefined loads and boundary conditions, thus enabling a particularly light structure with a total weight of less than 10 tonnes of the car's design mass. This corresponds to a weight saving of over 15 percent compared to existing freight cars with the same functionality. In addition, the prototype is equipped with an onboard system for condition monitoring. It continuously measures the condition of the two wheel axles and the track bed. This data can contribute to condition-based and predictive maintenance in the future. For better aerodynamics, the freight car is equipped with a cladding made of glass fibre composites. For the design and layout of this aerodynamic cladding, DLR has completed tests in the wind tunnel with the FR8Lab container – a rolling laboratory – which is also being showcased, as well as tests on special sections of track.

DLR at the InnoTrans Speakers' Corner

As part of the Speakers' Corner lecture series, DLR researcher Holger Dittus will report on the EU project FCH2RAIL. The project participants are developing and testing a new type of energy source for train applications: the Fuel Cell Hybrid PowerPack. It combines the electrical energy supply from the overhead line with the emission-free Hybrid PowerPack made of fuel cells and batteries. Power and range can be scaled according to a modular principle: The number of fuel cells and batteries influence the propulsion power. The capacity of the hydrogen tanks defines the range on non-electrified routes. For more than 18 months, the FCH2RAIL participants have been working intensively on the development of the Fuel Cell Hybrid PowerPack. It is now time to report on the latest highlights in the testing of the innovative PowerPack and the demonstrator train.

The presentation 'FCH2Rail Insights: Demonstration of the Fuel Cell Hybrid Power Pack' will take place on 22 September 2022 from 13:30 to 14:30 in Hall 7.2A. The presentation can also be followed via livestream on the InnoTrans website.