The Future of Wired Communication Infrastructure: Single Pair Ethernet

Article 1 from our SPE series: Single Paired Ethernet (SPE) makes Ethernet easy and affordable – and it can be used from the cloud to the smallest sensor.

This is the first of three articles exploring the topic of Single Pair Ethernet and its applications. This first article will introduce you to Single Pair Ethernet and the potential this technology has to elevate the potential of Industrie 4.0. The second article will discuss the fourth industrial revolution and the Industrial Internet of Things in more detail. Our last article will showcase some exciting case studies where SPE is making a huge difference in streamlining wired communication.

Introduction

As the Industrial Internet of Things (IIoT) and connected cars rapidly develop, the demand for a standardized, reliable, and effective communication network increases. Single Pair Ethernet or SPE is a high-performance Ethernet infrastructure that can meet this demand. SPE is a physical layer networking technology that uses a single pair of twisted copper wire rather than two or four pairs of conventional Ethernet - for fast communication with standard protocols across a range of applications including manufacturing and automotive. SPE is the tool to leverage the potential of IIoT and Industrie 4.0 and the next generation of connected vehicles.

A short history of Ethernet

Ethernet is the traditional technology for connecting devices in a wired local area network (LAN) or wide area network (WAN), enabling them to communicate with each other via a protocol - or a set of rules or common network language. An Ethernet cable is the physical, encased wiring over which the data travels.

Bob Metcalfe invented Ethernet at the Xerox Palo Alto Research Center in 1973. Metcalfe and his team developed and patented a "multipoint data connection system with collision detection" that later became known as Ethernet. Fortunately, they had the foresight to release Ethernet into the public domain so other companies could build to the specification. It was eventually adopted as an official standard by the International Electrical and Electronic Engineers (IEEE), paving the way for it to be accepted by corporate and government users worldwide. Other standards have been developed based on Ethernet, such as Fast Ethernet, Gigabit Ethernet, and Wi-Fi.

What exactly is SPE?

SPE is a physical layer networking technology that, as its name suggests, uses just a single pair of twisted copper wire. It delivers speeds of 10Mbit/s (10BASE-T1) up to 1,000 meters. 100Mbit/s (100BASE-T1) and 1Gbit/s (1000BASE-T1) up to 40 meters with a shielded cable or 15 meters with unshielded cable.

SPE and Industrie 4.0

Industrie 4.0, sometimes called the fourth industrial revolution, is a term used to describe the influence of the Internet of Things (IoT) on industry and the digitization of industrial processes. Industrie 4.0 is well upon us and resulting in a massive increase in analytics, peer-to-peer communication, and machine learning which are assisting the shift from manufacturing that aims to produce ever-larger volumes at decreasing costs, to producing individualized products at mass production costs.

This new form of manufacturing means more manufacturing equipment is equipped with sensors that are constantly collecting data used to monitor, regulate, and maintain automated systems. SPE permits the barrier-free connection of these sensors, other field devices, and actuator technology present in the smart manufacturing environment via end-to-end internet protocol (IP) based communications. The field level (i.e. the sensors or actuator themselves) now becomes smart and thus gives every sensor the ability to be individually monitored which results in the more efficient and cost-effective construction, operation, and maintenance of systems. For the first time, Ethernet can communicate efficiently from the cloud to the field level or sensor level.

In addition to essentially giving every sensor an IP address, SPE’s slim and lightweight physical properties mean reduced weight, reduced cost, smaller footprint, and easier installation as well as the possibility of connection to previously unattainable locations.

The achievement of leading goals of Industrie 4.0 including higher efficiency, flexibility, customization, and productivity with lower costs through automation demands consistent compatibility of devices, cables, and connectors that a standardized SPE infrastructure can deliver.

Simultaneous power supply and data

In addition to data transmission via Ethernet, SPE also enables a simultaneous power supply via PoDL - Power over Data Line. In the past, PoDL (Called PoE – Power over Ethernet in 4/8-pair Ethernet) required either two pairs of wire for Fast Ethernet (100MB) or four pairs for Gigabit Ethernet.

PoDL means machines, robotics, and other equipment can experience simultaneous power supply and data to devices with only one connection. This option provides a huge advantage over wireless solutions in many cases. In this instance, SPE can contribute to environmental compatibility and sustainability by eliminating the need for batteries and accumulators.

SPE in Automotive

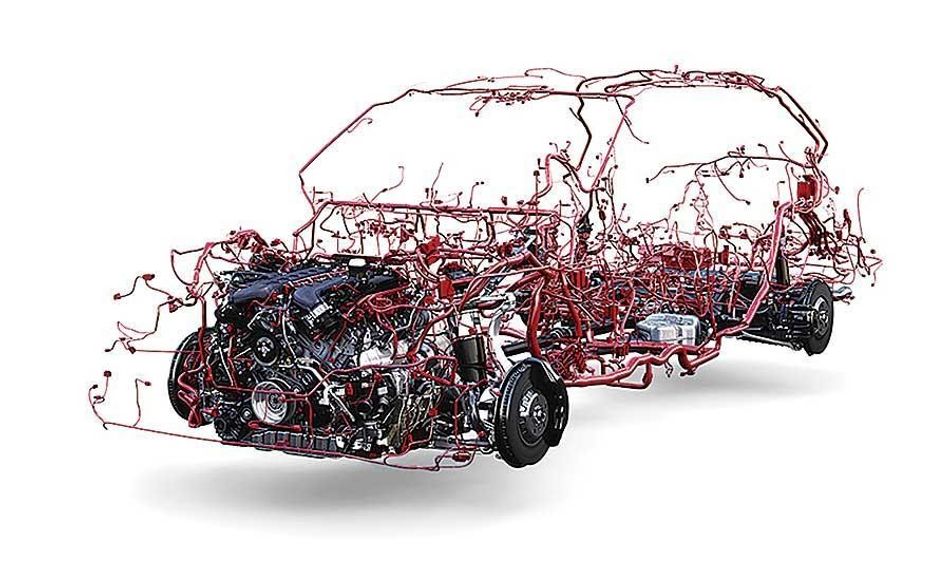

With significant increases in the volume and complexity of in-car electronics, networking solutions that offer low-cost, high-speed transmission and bandwidth are becoming ever more necessary. It’s estimated by 2030 that approximately 50% of a car's total cost will be related to electronics.

SPE is set to become the new standard for automotive for several reasons. First, it's significantly lighter and cheaper. The wiring harness of a modern car contributes to a significant amount of its total weight and as cars become more autonomous, this weight could rise with the addition of advanced vision systems. Any technology that reduces this weight directly contributes to fuel economy. Using single twisted-pair cabling allows manufacturers to deliver data at a rate of 1000 Mbps while reducing the overall weight of the car and cutting the overall cost of cabling.

Secondly, standardized networking of control devices and sensors will push innovations in the fields of driver assistance systems such as LiDAR, high-resolution displays, autonomous driving, 4K cameras, and infotainment by proving simpler, efficient and cost-effective wiring solutions.

A standardized approach

Standardization is critical for the rapid deployment and development of SPE. Users must be able to construct efficient network and cabling structures, from the sensors, through the control and company level, right through to the cloud, all based on standardized interfaces. In January 2020, the IEC standardization committee SC 48B published IEC 63171-6 as an international standard for Ethernet interfaces using only single pair wires following a more than two-year international selection process. The standard describes the T1 Industrial Style mating face, standardized by HARTING in 2016, as the internationally standardized default interface for SPE networks in industrial M3I3C3E3 environments.

Other relevant standards include the IEC 61156-x for standardization cables, ISO/IEC 11801 for Standardization cabling the standardized SPE protocol for data, and power IEEE 802.3. Each of these standards which relate to the different aspects of SPE infrastructure play a vital role in the scalability of the technology.

Increasing standardization gives planning security for the designers of new devices for IIoT infrastructure such as sensor and actuator technology providing them solid assurance to actively commence the implementation of SPE in the respective device technology.

The SPE Network

Driven by the increased networking requirements of IIoT and Industry 4.0, the ideal solution for wired communication infrastructure is single-pair Ethernet due to its combination of high transmission performance and space and weight. The broad rollout of SPE requires work and expertise from a broad range of players. A global partner network of both cable and chipset manufacturers as well as OEMs have made a united commitment to Single Pair Ethernet. This network will work together to ensure that SPE technology is pushed further and faster. Partnerships within the network will allow for increases in product and performance variations as well as smoother standardization processes. The founding members of the SPE Industrial Partner Network include HARTING, TE Connectivity, HIROSE, Würth Elektronik, LEONI, Murrelektronik, and Softing IT Networks. Currently the network has grown up to 35 member companies and is increasing weekly.

Conclusion

SPE is not a static technology, and dynamic improvements are emerging all the time. New standards and a collaborative networked approach to innovation will ensure SPE continues to be rolled out in manufacturing and automotive as well as find new applications. SPE brings forward many technological challenges that if addressed in a consolidated and ambitious manner will also deliver huge technological advancements.

This the first article of three on the topic of SPE. The next article will examine the role of SPE in automotive. The final article in the series will explore several case studies where SPE is driving innovation.

About the Sponsor: SPE Industrial Partner Network

The SPE Industrial Partner Network is the assurance of quality for uniform and coordinated infrastructure that meets set standards. The network represents stakeholders from all aspects of SPE technology. It is committed to spreading knowledge about the potential and development of SPE. You can join the SPE Pioneer Summit 2020 in November as well via this link.

Interested in learning more? You can join the SPE Pioneer Summit 2020 in November via this link.