The Metal 3D Printing Technology Report: Chapter 2: Metal 3D Printing Materials

The metal additive manufacturing market features various feedstock types, with powder being the dominant choice for LPBF, some DED methods, and binder jetting. Metal wire and bound metal filament are also used in specific technologies.

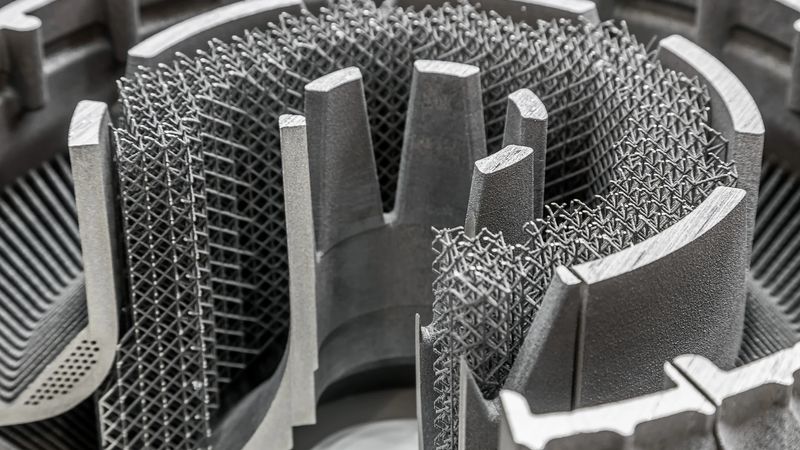

Credit: Tempus 3D

Understand the Future of Metal 3D Printing

The Metal 3D Printing Technology Report is your essential guide to the latest advances, applications, and real-world insights into additive manufacturing with metal. Packed with detailed case studies, practical information, and interviews with industry leaders, this report reveals how metal 3D printing is transforming industries and pushing the boundaries of manufacturing.

Read an excerpt from chapter 1 here or download the full report.

Metal 3D Printing Materials

The metal additive manufacturing materials market spans several metal grades and a handful of material feedstock types, accommodating the different printing technologies outlined in the previous chapter. The main metal feedstock type by some distance is powder, which is used in key technologies such as LPBF, some forms of DED, and binder jetting. Other feedstock types include metal wire, which is used in some forms of DED, and bound metal filament, which is used in metal extrusion technologies. Around 600 tons of additive manufacturing feedstock are consumed annually in powder, rod, or other forms.

Powders

Metal powders make up the majority of metal 3D printing materials. They are used in key processes—like LPBF, electron beam melting, DED, and binder jetting— and span many metals, grades, and alloys.

Common metal powders include:

Aluminum alloys

Cobalt chromium alloys

Copper alloys

Nickel alloys

Steels

Stainless steels

Tool steels

Case hardening steels

Titanium alloys

To ensure successful printing, metal powders must have good flow properties, a small range of particle sizes, and reasonably consistent particle shape, with spherical powders capable of the highest performance. Powders are usually developed for a specific printing process. Particle sizes for LPBF powders measure around 10–60 microns, while those for electron beam melting measure 60–105 microns. Binder jetting can benefit from finer particles.

Powders for metal additive manufacturing are most often produced via gas atomization. In this process, molten metal is forced through a nozzle before a stream of inert gas breaks it up into small, solid, spherical particles. An alternative production process is plasma atomization. In this process, wire feedstock is melted with a plasma torch, creating spherical particles. Plasma atomization is the superior process for producing highly spherical particles but is more expensive than gas atomization. It is typically used for high-value metals and applications.

Many companies manufacture metal powders for 3D printing. The largest of these have previously been active in powder metallurgy prior to the rise in metal 3D printing seen in the last two decades.

Leading powder producers include:

GKN Powder Metallurgy: Part of the UK’s Dowlais Group plc. Produces most types of metal powder, for LPBF, DED, and binder jetting. Also makes dual-phase and custom alloys for additive manufacturing.

Höganäs AB: The world’s largest producer of metal powders, based in Sweden. Uses gas atomization to produce a large portfolio of powders for LPBF, EBM, DED, binder jetting, and cold spray. Also develops custom powders.

Sandvik AB: A multinational engineering company and major powder producer based in Sweden. Has been producing gas-atomized powders for 45 years in a range of particle sizes to suit different technologies.

Metal powders for additive manufacturing require strict safety considerations. Fine particle sizes pose a risk as they can be easily inhaled. PPE is required during powder handling and machine operation, and care should be taken to prevent the spread of powder outside of dedicated operating space. Some powders (aluminum, titanium) pose a fire risk so prevention of electrostatic buildup should be established. Industrial additive manufacturing users may install an automated powder handling solution to prevent risk and maximize efficiency.

Wire Feedstock

Metal wire feedstock is less widely used than metal powders, as it is compatible with fewer processes. However, it is used with certain DED technologies, including Wire Arc Additive Manufacturing (WAAM) and Electron Beam Additive Manufacturing (EBAM) from Sciaky. Advantages of wire feedstock include simpler and safer material handling, lower cost, and reduced material waste, though resolution is limited. Wire may be produced using the wire rod reduction or metal strip forming processes.

Common metal wire types include:

Aluminum alloys

Cobalt chromium alloys

Copper alloys

Nickel alloys

Refractory metals

Niobium

Tantalum

Tungsten

Steels

Stainless steels

Tool steels

Case hardening steels

Titanium alloys

In general, wire printing technologies can process ordinary welding wire feedstock. This means the material range for such technologies is slightly wider than powder processes. At present, refractory metals like tungsten are more readily available in wire feedstock than powder. However, although many machines support the processing of standard welding wire, several companies manufacture wire feedstock specially formulated for additive manufacturing.

3D printing wire producers include:

Alloy Wire International (AWI): British manufacturer of high-performance exotic alloys established in 1946.

Fortius Metals: Colorado-based specialist in welding wire for large-format 3D printing. Offers custom material development service.

WAAM3D Ltd.: A leader in WAAM hardware and materials based in the UK. Its wire feedstock includes five aluminum alloys in 1.2 mm diameter.

Wire requires fewer safety considerations than metal powder, greatly reducing facility and labor costs, as there is no air particulate risk. In general, PPE is not required for wire material handling and vacuum cleanup after use is not necessary. Wire also poses minimal storage risks and has a long shelf life if kept in a relatively dry environment.

Bound Metal Feedstock

Extrusion-style metal 3D printing systems can process bound metal materials, typically as filament or rod feedstock. These materials consist of metal powders encased within a wax and polymer matrix (binder) material that must be removed via thermal or chemical processing after printing. One of the most popular materials in this category, BASF Ultrafuse 316L, uses a 4:1 ratio of metal powder to binder. Such materials may be printed on specialist metal 3D printing hardware such as the Desktop Metal Studio System or on adapted FFF machinery normally used for printing thermoplastics, such as the UltiMaker Metal Expansion Kit, which makes it possible to process metal filaments on the UltiMaker S5 and S7 3D printers.

Common bound metal materials include:

Copper

Nickel alloy Inconel 625

17-4PH Stainless Steel

316L Stainless Steel

H13 Tool Steel

A2 Tool Steel

D2 Tool Steel

4140 Low-Alloy Steel

Ti64 Titanium

Advantages of bound metal feedstock include simpler material handling, safety advantages, and compatibility with low-cost machinery. Disadvantages include a limited material selection and slower overall production times due to the speed of the extrusion process and the extensive post-processing required.

“There is a need for more materials,” says Andre Gasperini, Product Manager at UltiMaker. “Limited material availability is one of the key challenges to enriching the range of applications for metal FFF and going to new markets.”

Several companies make bound metal materials for 3D printing. These include manufacturers of extrusion 3D printing hardware such as Desktop Metal and Markforged, as well as larger material companies like BASF, whose Ultrafuse composite filaments have become an industry standard.

Bound metal material producers include:

BASF: The world’s leading chemical company, headquartered in Germany. Makes Ultrafuse 316L and Ultrafuse 17-4 PH stainless steel filaments for FFF printers.

Desktop Metal: Disruptive metal additive manufacturing company, recently acquired by Nano Dimension. Makes copper, nickel, low-alloy steel, stainless steel, tool steel, and titanium rods for extrusion.

Markforged: Close competitor of Desktop Metal in low-cost metal 3D printing. Makes copper, Inconel 625, stainless steel, and tool steel bound filaments for extrusion.

In terms of safety and handling, bound metal feedstock has more in common with ordinary thermoplastic filament than fine particle metal powders. Most bound metal materials and their suitable systems can be used in non-laboratory environments with fewer PPE and storage requirements than powders.

Read an excerpt from the chapters here:

Introduction Chapter

The Metal 3D Printing Technology Report is your essential guide to the latest advances, applications, and real-world insights into additive manufacturing with metal.

In the first chapter of our new report, we examine the dominant methods of metal 3D printing—metal laser powder bed fusion (LPBF), directed energy deposition (DED), metal extrusion, and binder jetting—as well as other still-emerging or more niche processes.

Chapter 2

The metal additive manufacturing market features various feedstock types, with powder being the dominant choice for LPBF, some DED methods, and binder jetting. Metal wire and bound metal filament are also used in specific technologies.

In this chapter, we separate metal AM post-processing into four categories: debinding and sintering, CNC machining and milling, heat treatment, and quality assurance.

Metal 3D printing offers significant design opportunities with its high geometrical freedom, but it requires careful design for additive manufacturing (DfAM) to address equipment and material constraints, a process supported by DfAM and 3D printing simulation tools in most major CAD software.

This chapter of the report will lay out and examine the various applications of metal additive manufacturing, with a particular focus on end-use applications in the dominant metal AM adoption industries.

In this chapter, we present three exclusive interviews with industry experts from Xometry, UltiMaker, and Aibuild, key sponsors of the Wevolver Metal 3D Printing Technology Report.

Or download the full report below

About UltiMaker

UltiMaker is a global leader in 3D printing, focused on shaping the future of manufacturing and product development. With a wide range of cutting-edge 3D printing solutions, including the popular S...

125 Posts

- 8 Specs

About Xometry Europe

Xometry Europe, a leading on-demand manufacturing platform, offers dozens of manufacturing processes and materials, from CNC machining, sheet metal fabrication and injection moulding, to complex 3D...

46 Posts

About Aibuild

Aibuild is a fast-growing London based Software-as-a-Service company, that is transforming the Additive Manufacturing industry on a global scale. Our clients are tier 1 companies operating in the...