The most popular 3D printing materials in FDM and their properties

3D printing works with a wide variety of 3D printing materials, among which we can find plastics, resins, metals… and even food! In FDM printing, thermoplastics are used, a type of 3D printer material that at high temperatures becomes liquid allowing it to flow, and when it cools down enough (below its glass transition temperature) it becomes solid.

The most popular 3D printing materials in FDM and their properties

In this article, you will find the most 3D printing materials for 3D printers in the world of FDM printing, and some with very interesting properties.

A quick list of the 3D printing materials we’ll run through:

- PLA

- ABS

- PET-G

- TPU

- PVA

- PP

- PA

- Composite materials

- Fiber-filled materials

- Metals

PLA

Polylactic acid, more commonly known as PLA, is the most widely used 3D filament because it is so easy to print. This plastic is made from vegetable starches, having the property of being biodegradable and being able to melt at low temperatures.

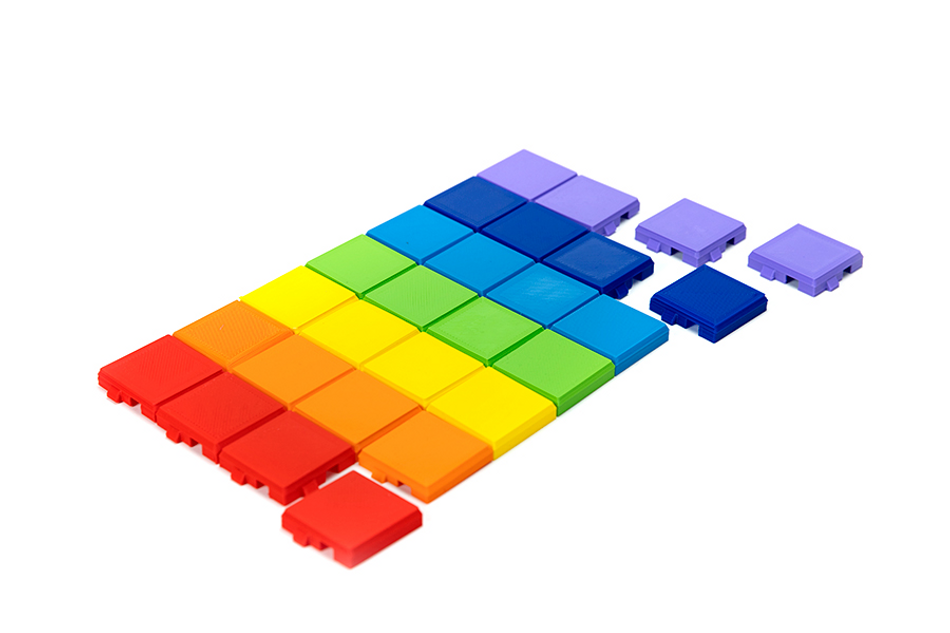

This material comes in a wide range of colors, which makes it ideal for prototyping or applications where the aesthetics of the object is paramount.

ABS

This plastic is highly used at all professional levels due to its physical properties, being one of the most resistant 3D printing materials due to its high impact resistance and very good tolerance to high temperatures. In terms of chemical resistance, ABS is affected by various solvents and acids, however, it is a property that can be taken advantage of as it allows polishing the surface of the part with an acetone vapor bath, giving it a smooth and shiny finish.

To print this material correctly, it is necessary to have a closed printer to maintain the heat during the manufacturing process. This will keep the ABS from shrinking during the printing of the model and suffering from problems such as warping or cracking.

(You will probably never call ABS by its full name, but here it is in case you are wondering: Acrylonitrile Butadiene Styrene.)

PET-G

PET-G (glycolized polyethylene terephthalate) is another material widely used in the 3D printing world and could be said to be an intermediate between PLA and ABS. This plastic has good mechanical strength (somewhat lower than ABS) but good chemical resistance, in addition to being easy to print.

Some applications for PET-G are the manufacture of impact-resistant parts, decorative objects and food packaging, making it the most versatile 3D printer material available.

TPU

It is one of the most popular flexible materials in the world of 3D printing. Thermoplastic polyurethane is resistant to friction and wear, which makes it an interesting material to make coatings or protections.

You can find TPU in different degrees of hardness, the most rigid ones being the easiest to print. Consequently, the best advice when printing this material is to print at a low speed, as it will prevent the filament from deforming and jamming.

PVA

With the emergence of the multi-material printing system for 3D printers, support materials emerged. PVA or polyvinyl alcohol is a soluble support material, ideal for printing parts with complex geometries that make it difficult to extract support structures printed with the same material.

PVA is water-soluble and allows to obtain a better surface finish on the contact surface of the support.

We advise you to store this material in a dry and hermetically sealed place so that it is always dry and ready to be used in your 3D printer.

PP

Polypropylene, or PP, is a filament widely used in the industrial sector for the manufacture of functional parts due to its resistance to impact and abrasion, but above all for its excellent resistance to chemicals.

In addition, this material is very light and relatively flexible, so it can be used to create protective elements that are in contact with the skin, such as the inside of helmets and supports for face shields.

Polypropylene is a difficult 3D printer material to print because of its high warping, it is ideal to have a closed printer to have a warm environment to avoid warping and to make use of brim/edge in the adhesion settings to the printing surface.

PA

Nylons or polyamides are materials characterized by their capacity to work continuously at temperatures up to 120ºC. They have high mechanical strength, which makes them ideal for mechanical parts, connectors, protective housings, among others.

It is a hygroscopic 3D printer material (it absorbs a lot of moisture), affecting its thermo-mechanical properties and making it difficult to print, so it is recommended to store it properly. The BCN3D Smart Cabinet has been designed to be the ideal place to store your filaments and keep them dry.

Composite materials

Some materials are born from the mixture of several polymers to obtain better physical properties, such as Tough PLA, which is the result of the union of PLA and ABS, giving it greater impact resistance than PLA but retaining its ease to be printed.

Many of these materials are based on PLA and can be found mixed with wood particles, clays, and metals, increasing the range of materials that can be 3D printed.

Fiber-filled materials

With the entry of 3D printing in the industrial sector, the need has arisen to use materials that are increasingly resistant to mechanical stress and corrosive environments, resulting in the birth of materials with loads of glass and carbon fibers. After metal, this type of material for 3D printers is one of the most resistant materials.

Polypropylene with glass fiber (PP GF) has the high chemical resistance of polypropylene but with a mechanical strength highly enhanced by glass fibers.

High-temperature polyamide with carbon fiber (PAHT CF) is a material that combines the high-temperature tolerance of polyamide with astronomical mechanical strength.

Polyethylene terephthalate with carbon fiber (PET CF) is a material positioned between the good properties of PP GF and PAHT CF, offering good chemical, thermal and mechanical resistance.

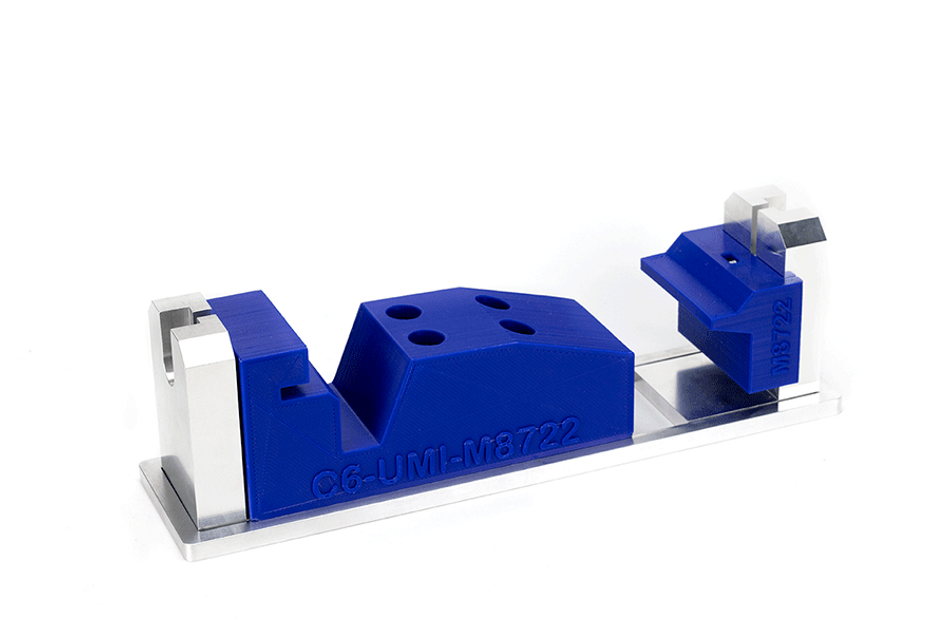

Metals

Along with fiber-based materials, metals have been another of the industrial sector’s main attractions, and 3D printing with FDM technology has been able to adapt to them. This type of materials for 3D printers are composed of a high degree of metal powders and a part of binder polymers. In order to manufacture functional parts with these materials, it is necessary to go through a process of removing the binder material and sintering, after printing the part.

Once the part has been synthesized, you can perform post-processing tasks such as polishing, milling, threading, turning, and welding, among others.

This process allows the production of small series of metal parts at a very low cost compared to traditional manufacturing technologies such as CNC and casting.

Conclusions

- ABS is a highly used material for 3D printers and one of the most resistant, only surpassed by materials with fibers and metals.

- There are hybrid materials that are born from the union of two polymers or the addition of fibers, to obtain better physical properties.

- 3D printers with FDM technology have the capacity to print engineering materials such as metals.

Want to find out even more about the properties of this filament? Check out this article!