What is 3D Printer Thermal Runaway and How to Prevent It

Thermal runaway is a serious issue that can occur when using an FDM 3D printer. If unaddressed, it can lead to damaged 3D printer components or even fire. Here’s how to recognize thermal runaway, prevent it, and, if needed, fix it.

Thermal runaway can lead to 3D printer damage or, in severe cases, fire.

Thermal runaway is a serious issue that can occur when using an FDM 3D printer. If unaddressed, it can lead to damaged 3D printer components or even fire. Here’s how to recognize thermal runaway, prevent it, and, if needed, fix it.

Thermal runaway is a dangerous phenomenon that can occur in FDM 3D printers when the temperature of the heating elements, such as the hotend or heated bed, rises uncontrollably. This can lead to severe damage to the printer, and in extreme cases, can even cause fires. Understanding and preventing thermal runaway is crucial for ensuring the safety and longevity of your 3D printer. In this article, we will explore the causes of thermal runaway, discuss preventive measures, and provide guidance on troubleshooting and resolving issues related to this phenomenon. By gaining a deeper understanding of thermal runaway, you can take proactive steps to protect your 3D printer and maintain its optimal performance.

What is Thermal Runaway?

Generally, speaking thermal runaway refers to a self-sustaining, uncontrolled increase in temperature that occurs when a heating element's heat generation surpasses its heat dissipation capabilities. Put another way, the energy of the heated component itself starts to generate heat, leading to dramatic, and accelerated temperature increases. Thermal runaway is a particularly important problem when it comes to batteries, and especially lithium ion batteries.[1]

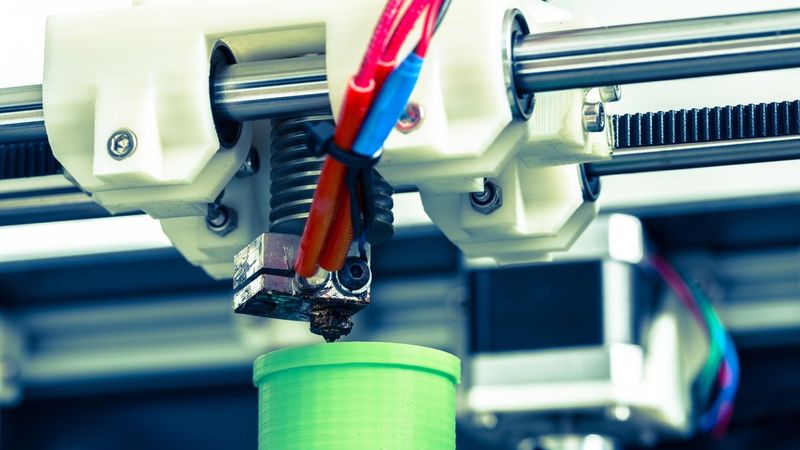

In the context of 3D printing, the thermal runaway phenomenon typically involves the hotend, which is responsible for heating the filament to its melting temperature for extrusion. It is also possible for thermal runaway to take place when printing with a heated print bed. When thermal runaway occurs in a 3D printer, the temperature of the hotend or bed can rise above the set temperature, which can cause serious damage to the printer's components, such as melting plastic parts or damaging electronic components. In extreme cases, thermal runaway can even lead to fires, posing a significant safety risk to users.

What Causes Thermal Runaway in 3D Printers?

The general cause of thermal runaway in 3D printers is a malfunction or failure in the temperature control system. The temperature control system consists of a temperature sensor—such as a thermistor or thermocouple—and a heating element, such as a heater cartridge (for the hotend) or a resistive heating pad (for the print bed).[2] The temperature sensor monitors the temperature of the heating element and sends this information to the printer's control board, which adjusts the power supplied to the heating element to maintain the desired temperature. If the temperature sensor fails or becomes disconnected, this communication will be lost and the control board can continue to supply power to the heating element, causing the temperature to rise in an uncontrolled way. It is this phenomenon that is known as thermal runaway. Here are some of the specific causes of thermal runaway in 3D printers:

Faulty Temperature Sensors

One common cause of thermal runaway in 3D printers is a faulty temperature sensor, such as a thermistor or thermocouple. These sensors are responsible for monitoring the temperature of the heating elements and sending feedback to the printer's control board. Over time, however, these sensors can become more resistant to heat, which leads to a discrepancy between the actual temperature and the measured temperature. This is known as drift. Ultimately, a faulty sensor is an issue because if it can’t provide accurate readings, the control board won’t be able to accurately regulate the temperature, leading to an uncontrolled rise in temperature.

Loose Connections or Damaged Wiring

Loose connections or damaged wiring between the heating element and the temperature sensor can also contribute to thermal runaway. If a wire becomes disconnected or damaged, the temperature sensor may lose its connection to the control board, causing the board to lose control over the heating element. This can result in the heating element continuing to heat up without any regulation. In some cases, damaged wiring can also cause short circuits, which can lead to rapid temperature increases and potential fires.

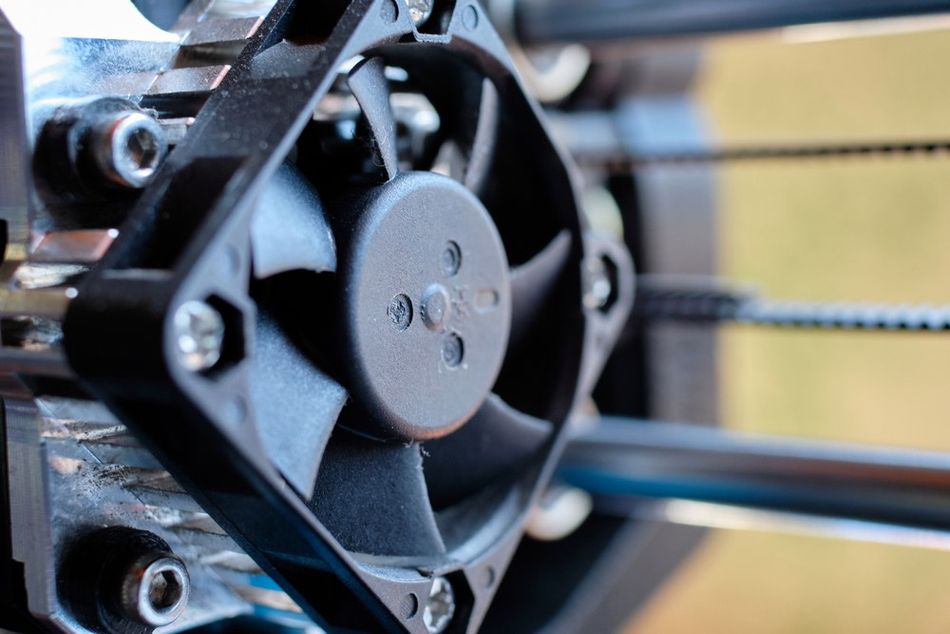

Inadequate Cooling Systems

Inadequate cooling systems can be another factor in thermal runaway. 3D printers rely on cooling fans and heat sinks to dissipate heat generated by the hotend and other components. If the cooling system is not functioning properly, heat may accumulate, causing the temperature to rise uncontrollably. Factors that can contribute to inadequate cooling include blocked air vents, malfunctioning fans, or improperly installed heat sinks. At the same time, over cooling (which can be caused by cold ambient temperatures or excessive air flow) can also cause the heating element to overcompensate, potentially leading to thermal runaway.

Software or Firmware Issues

Software or firmware issues can also play a role in thermal runaway. For instance, incorrect temperature settings in the slicing software or firmware can cause the printer to heat up beyond safe limits. Additionally, firmware bugs or outdated firmware versions may lack proper safety features, such as thermal runaway protection, which can leave the printer vulnerable to uncontrolled temperature increases.

Mechanical Failures

Mechanical failures, such as a jammed extruder, can also lead to thermal runaway. When the extruder is jammed, the filament cannot be extruded, and the heat generated by the hotend has nowhere to go. This can cause the temperature to rise rapidly, potentially leading to thermal runaway. Understanding the various causes of thermal runaway in 3D printers is essential for identifying potential issues and taking preventive measures to ensure the safety and performance of your printer.

Recommended reading: What is FFF 3D printing?: An introduction to 'fused filament fabrication' technology

How to Prevent Thermal Runaway

Thermal runaway is a serious issue in 3D printing that requires preventative strategies. By following and implementing the following steps, you can help to protect your 3D printer from damage caused by thermal runaway.

Ensure Proper Maintenance

Regular maintenance of your 3D printer is essential for preventing thermal runaway. By routinely checking on your printer and its various components, you can identify potential issues before they escalate into more significant problems. Key components to inspect include the temperature sensors, heating elements, wiring, and connectors.

When examining the hotend and heated bed temperature sensors, ensure they are securely attached to the heating elements and that there are no signs of damage or wear. A loose or damaged sensor may provide inaccurate temperature readings, leading to improper temperature control and increasing the risk of thermal runaway.

You should also regularly inspect your printer’s heating elements (the hotend and bed) for signs of wear or damage, such as cracks or corrosion. Damaged heating elements may not function correctly, potentially causing temperature fluctuations and, in extreme cases, thermal runaway. Additionally, check the wiring and connectors for any signs of fraying, loose connections, or corrosion, as these issues can also contribute to temperature control problems.

Firmware Safety Features

Firmware plays a crucial role in preventing thermal runaway in 3D printers by implementing safety features that monitor and control temperature. One such feature is thermal runaway protection, which is designed to detect abnormal temperature fluctuations and shut down the printer if any temperature discrepancies or inaccuracies occur.

Thermal runaway protection works by continuously monitoring the temperature readings from the sensors and comparing them to the target temperature set by the user. If the temperature deviates significantly from the target for a specified period, the firmware assumes that there is a problem with the temperature control system and takes action to prevent thermal runaway. This action will effectively shut down the heating elements and display a thermal runaway error message on the printer's control panel.

To enable and configure thermal runaway protection, users need to access their printer's firmware settings. This process can vary depending on the printer model and firmware used, but it generally involves connecting the printer to a computer and using a firmware configuration tool or editing the firmware's source code directly. Some popular options, such as RepRap, Repetier, and Marlin firmware, include thermal runaway protection by default, but it’s still a good idea to check that the safety feature is enabled.[3]

In some cases, firmware settings may require configuration to suit the specific printer model. When configuring thermal runaway protection, users should pay attention to parameters such as the allowed temperature deviation, the duration for which the deviation must persist before triggering the protection, and the action to be taken when the protection is triggered. These settings should be tailored to the specific printer model and its components to ensure optimal performance and safety. Additionally, if you replace your printer’s thermistor, make sure that the firmware program is updated to reflect the new thermistor’s beta value.

If you’re not sure whether your 3D printer has thermal runaway protection, there is an easy way to test it. Simply disconnect the thermistor or temperature sensor from the printer’s heating element and set a printing temperature. If thermal runaway protection feature is active, the printer should automatically turn off and show an error message after about a minute.

Hardware Upgrades and Modifications

Last but not least, upgrading or modifying your 3D printer's hardware can help prevent thermal runaway by improving temperature control and monitoring capabilities. Some common hardware upgrades that can enhance the safety and performance of your printer include:

Upgraded Temperature Sensors: Replacing the stock temperature sensors like thermistors, which are cheap and easy to install, with higher-quality alternatives, such as platinum resistance thermometers (PT100 or PT1000 sensors), can provide more accurate and stable temperature readings. These sensors have a higher temperature range and better accuracy compared to standard thermistors, which makes them more suitable for high-temperature materials) and reduces the risk of temperature control issues that can lead to thermal runaway.

Silicone Socks for Hotends: Silicone socks are insulating covers that fit over the hotend's heater block, helping to maintain a stable temperature and reduce heat loss. By improving temperature stability, silicone socks can help prevent temperature fluctuations that could contribute to thermal runaway. They are also effective at protecting the printhead from filament residue and debris, which can also impact temperature control.

Upgraded Cooling Systems: Improving the cooling capabilities of your 3D printer can help prevent thermal runaway by ensuring that heat is effectively dissipated from the hotend and other components. Upgrades to consider include more powerful cooling fans and larger heat sinks. Enhanced cooling systems can help maintain a stable temperature, reducing the risk of thermal runaway.

Reliable Power Supply Units (PSUs): A high-quality power supply unit (PSU) can provide more stable and consistent power to your 3D printer's components, reducing the risk of voltage fluctuations that can impact temperature control. Look for PSUs with built-in safety features, such as over-temperature protection and short-circuit protection, to further enhance the safety of your printer.

By investing in hardware upgrades and modifications, you can improve the safety and performance of your 3D printer, reducing the risk of thermal runaway and ensuring a more reliable printing experience.

Recommended reading: Ender 3 Extruder Skipping: Causes, Solutions, and Preventive Measures

Troubleshooting Thermal Runaway Issues

Obviously prevention is important when it comes to thermal runaway, but for those facing the problem, it’s also vital to know how to identify it and fix it. Here are some helpful tips when it comes to troubleshooting temperature control problems caused by hardware or firmware issues.

Identifying Symptoms and Causes

When troubleshooting thermal runaway issues in 3D printers, the first step is to identify the symptoms and determine the root cause of the problem. Common symptoms of thermal runaway include:

Unexpected temperature fluctuations: If the temperature of the hotend or heated bed is unstable or deviates significantly from the target temperature, it may indicate an issue with the temperature control system, such as a faulty sensor or heating element.

Printer shutdown or error messages: Many 3D printers with thermal runaway protection will shut down or display an error message when the protection is triggered. This can be a clear indication that a thermal runaway issue is occurring.

Physical damage or deformation: In severe cases of thermal runaway, the excessive heat can cause visible damage to the printer's components, such as melted plastic parts or discolored metal components.

Once the symptoms have been identified, the next step is to determine the cause of the issue. This process may involve inspecting the printer's components, checking the firmware settings, and reviewing the slicing software settings. As we saw in the previous section common causes of thermal runaway include faulty temperature sensors, damaged wiring or loose connections, inadequate cooling, and software or firmware issues. By identifying the symptoms and causes of thermal runaway, you can take targeted action to resolve the issue and prevent it from recurring, ensuring the safety and performance of your 3D printer.

Resolving Hardware Issues

Here are some of the most common hardware issues that can lead to thermal runaway and steps to fix them:

Faulty Temperature Sensors: If a temperature sensor is faulty or providing inaccurate readings, it may need to be replaced. To diagnose a faulty sensor, you can use a multimeter to measure its resistance at room temperature and compare it to the manufacturer's specifications. If the resistance is significantly different from the expected value, the sensor may be faulty and should be replaced with a compatible (and preferably higher quality) alternative.

Loose Connections or Damaged Wiring: Inspect the wiring and connectors, particularly where the thermistor connects to the heating element, for signs of damage, such as fraying, loose connections, or corrosion. If you find any issues, repair or replace the damaged wiring or connectors. This will help to ensure a stable connection between the temperature sensor and the control board. When replacing wiring, use high-quality, heat-resistant wires to minimize the risk of future issues.

Inadequate Cooling Systems: If the cooling system is not functioning properly, it may need to be repaired or upgraded. Check for blocked air vents, malfunctioning fans, or improperly installed heat sinks. Clean any debris from the air vents and fans, and ensure that the heat sinks are securely attached to the components they are meant to cool. If necessary, consider upgrading the cooling system with more powerful fans or larger heat sinks to improve heat dissipation.

Mechanical Failures: Address any mechanical failures, such as a jammed extruder or a stuck heated bed, that may be contributing to thermal runaway. To resolve a jammed extruder, disassemble the extruder assembly, clean any debris or filament residue, and reassemble it, ensuring that all components are properly aligned and functioning smoothly. For a stuck heated bed, inspect the bed's movement mechanism, such as the linear rails or bearings, and repair or replace any damaged components as needed.

If you are unsure about your ability to diagnose and repair the problem, consult a professional technician or the printer's manufacturer for assistance. By addressing hardware issues promptly and effectively, you can minimize the risk of thermal runaway and ensure the safety and performance of your 3D printer.

Recommended reading: How to Clean 3D Printer Nozzles and Prevent Clogs

Resolving Firmware and Software Issues

Firmware and software issues can contribute to thermal runaway in 3D printers by causing temperature control problems or disabling safety features. To troubleshoot and resolve these issues, consider the following steps:

Update Firmware and Software: Ensure that your 3D printer's firmware and slicing software are up to date. Developers frequently release updates that include bug fixes, performance improvements, and new safety features. Updating to the latest version can help resolve issues related to thermal runaway and improve the overall performance of your printer.

Check Temperature Settings: Verify that the temperature settings in your slicing software are appropriate for the material you are using. Incorrect temperature settings can cause the printer to heat up beyond safe limits, increasing the risk of thermal runaway. Consult the filament manufacturer's recommendations for optimal printing temperatures and adjust your settings accordingly.

Enable and Configure Safety Features: Ensure that safety features, such as thermal runaway protection, are enabled and properly configured in your printer's firmware. As mentioned earlier, some firmware options, like Marlin and Repetier, include thermal runaway protection by default, but it may be disabled or require configuration.

Take safety precautions: While this isn’t a thermal runaway “fix”, it is still important to consider taking some safety precautions while 3D printing, particularly if your machine doesn’t have thermal runaway protection. At its worst, thermal runaway is a fire hazard, so think about clearing your 3D printing space from flammable materials and objects and about having a fire extinguisher in the vicinity.

Conclusion

Thermal runaway is a critical safety concern for 3D printer users, as it can lead to severe damage to the printer and even pose a fire risk. By understanding the causes of thermal runaway and implementing preventive measures, such as regular maintenance, firmware safety features, and hardware upgrades, you can minimize the risk of this problem occurring. Additionally, being able to troubleshoot and resolve thermal runaway issues is essential for maintaining the safety and performance of your 3D printer. By taking a proactive approach to thermal runaway prevention and management, you can ensure a safer and more reliable 3D printing experience.

Frequently Asked Questions about Thermal Runaway (FAQs)

Q: What is thermal runaway in 3D printers?

A: In 3D printing, thermal runaway refers to a phenomenon in which the printer’s heating elements (either hotend or heated bed) overheat beyond the print or bed temperature. This uncontrolled increase in temperature is often caused by a malfunction in the printer’s temperature control system, and can lead to serious issues like printer damage and fires.

Q: What causes thermal runaway in 3D printers?

A: Common causes of thermal runaway in 3D printers include faulty temperature sensors, loose connections or damaged wiring, inadequate cooling systems, software or firmware issues, and mechanical failures.

Q: How can I prevent thermal runaway in my 3D printer?

A: Preventing thermal runaway involves regular maintenance and inspection of your printer's components, enabling and configuring firmware safety features such as thermal runaway protection, and upgrading or modifying hardware components to improve temperature control and monitoring capabilities.

Q: How do I troubleshoot thermal runaway issues?

A: First, identify thermal runaway symptoms and determine the cause of the problem. This may include inspecting the printer's components, checking firmware settings, and reviewing slicing software settings. Once the cause is identified, targeted action can be taken to resolve the issue and prevent it from recurring.

Q: What are some hardware upgrades that can help prevent thermal runaway?

A: Hardware upgrades that can help prevent thermal runaway include upgrading temperature sensors, installing silicone socks on hotends, improving cooling systems, and using reliable power supply units with built-in safety features.

References

[1] Warner JT. Lithium-ion battery chemistries: a primer. Elsevier; 2019 May 10. Available from: https://doi.org/10.1016/B978-0-12-814778-8.00003-X

[2] What is a Thermistor [Internet]. EI Sensor, 2023. Available from : https://www.ei-sensor.com/what-is-a-thermistor/

[3] Configuring Marlin: Thermal Protection [Internet]. Marlin, 2023. Available from: https://marlinfw.org/docs/configuration/configuration.html#thermal-protection

Table of Contents

What is Thermal Runaway?What Causes Thermal Runaway in 3D Printers?Faulty Temperature SensorsLoose Connections or Damaged WiringInadequate Cooling SystemsSoftware or Firmware IssuesMechanical FailuresHow to Prevent Thermal RunawayEnsure Proper Maintenance Firmware Safety FeaturesHardware Upgrades and ModificationsTroubleshooting Thermal Runaway IssuesIdentifying Symptoms and CausesResolving Hardware IssuesResolving Firmware and Software IssuesConclusionFrequently Asked Questions about Thermal Runaway (FAQs)References