What is Thermoforming and what is it used for?

Thermoforming is a plastic manufacturing process where a thermoplastic sheet is deformed into a specific shape. The process starts with the heating of a flat plate like sheet of plastic which is then manipulated by either applying pressure or using a vacuum.

Tags

This article was first published on

www.engineeringclicks.comMaterials

There are also many different materials which can be used in the thermoforming process which include:-

- Polystyrene

- Cellulose acetate butyrate

- Cellulose acetate

- ABS

- Acrylic

- PVC

- Polypropylene

- Polyethylene

Mechanical Design Guidelines

To ensure you get the best out of the thermoforming process there are a number of guidelines to consider. These include:-

- Maximum section thickness for this process is about 3 mm. It doesn’t depend on the material being used but the minimum section thickness for this process is material dependent. It is normally between 0.05 to 0.5 mm

- The minimum cross section dimension limit is 25mm square with a maximum length and width of 7.5 m * 2.5 m

- For the draft angle in each product this process has a limit of 1 degree or greater

- The tolerance range for this procedure depends on the mould – typical range is between 0.025 mm to 2 mm

- For thickness of product the tolerance limit is high, typical value is about 20 percent

- If a product has corners the radii should be greater than the product thickness

- Products with large surface areas and features like holes cannot be manufactured using this process

- Features like lettering, ribs and bosses can be manufactured but at very high cost

- Moderate shape complexity can be achieved

Process Variations

It will come as no surprise to learn that there are now a number of variations on the base process. This allows the process to be adapted to best suit an array of different products/materials. Some of the variations include:-

Negative Pressure Process

The negative pressure process for thermoforming is where a vacuum is created inside the mould to force the plastic sheet to take the shape of mould. The pressure limit for this process is about 1 atm. To make the vacuum inside the mould, air is removed using a suction pump attached to holes drilled in the mould base.

Thermoforming is a plastic manufacturing process where a thermoplastic sheet is deformed into a specific shape. The process starts with the heating of a flat plate like sheet of plastic which is then manipulated by either applying pressure or using a vacuum. The process is also know by a number of other names such as:-

- Vacuum Thermoforming

- Pressure Thermoforming

- Blow Thermoforming

- Mechanical Thermoforming

The process of Thermoforming

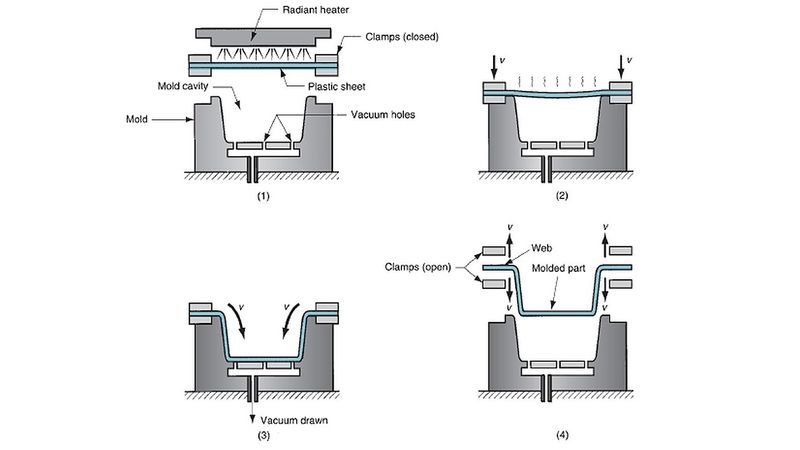

The thermoforming process can be broken down into two basic steps, heating and forming. The heating apparatus consists of radiant heaters. The heaters are attached to the top section of apparatus and placed at equal distance from each other. Plastic sheet is the raw material used and is secured on the top of the mould cavity with the help of the clamps. For deformation purpose the force is created ether using a vacuum only or vacuum with air pressure. Whichever process is used, holes are drilled into the bottom of the mould. The plastic sheets are held in place by clamps as the radiant heaters apply heat to the surface. When the sheet is soft enough it is pulled down into the mould by vacuum pressure. As a result of pressure the sheet takes the shape of mould and is removed after solidification.

Applications for Thermoforming

There are many different products/processes which make use of thermoforming such as:-

- Open type plastic panels and containers

- Food containers and packaging

- Refrigerator internal door

- Plastic sign boards and signs

- Home appliances like sink unit, bath tubs and shower panels

- Parts of automotive – specially interior (video below)

- Dinghy hulls

- Contoured skylights

- Electrical enclosures

- Braille text pages

- Electrical cabinet

Materials

There are also many different materials which can be used in the thermoforming process which include:-

- Polystyrene

- Cellulose acetate butyrate

- Cellulose acetate

- ABS

- Acrylic

- PVC

- Polypropylene

- Polyethylene

Mechanical Design Guidelines

To ensure you get the best out of the thermoforming process there are a number of guidelines to consider. These include:-

- Maximum section thickness for this process is about 3 mm. It doesn’t depend on the material being used but the minimum section thickness for this process is material dependent. It is normally between 0.05 to 0.5 mm

- The minimum cross section dimension limit is 25mm square with a maximum length and width of 7.5 m * 2.5 m

- For the draft angle in each product this process has a limit of 1 degree or greater

- The tolerance range for this procedure depends on the mould – typical range is between 0.025 mm to 2 mm

- For thickness of product the tolerance limit is high, typical value is about 20 percent

- If a product has corners the radii should be greater than the product thickness

- Products with large surface areas and features like holes cannot be manufactured using this process

- Features like lettering, ribs and bosses can be manufactured but at very high cost

- Moderate shape complexity can be achieved

Process Variations

It will come as no surprise to learn that there are now a number of variations on the base process. This allows the process to be adapted to best suit an array of different products/materials. Some of the variations include:-

Negative Pressure Process

The negative pressure process for thermoforming is where a vacuum is created inside the mould to force the plastic sheet to take the shape of mould. The pressure limit for this process is about 1 atm. To make the vacuum inside the mould, air is removed using a suction pump attached to holes drilled in the mould base.

Positive Pressure Process

This thermoforming process uses air pressure in order to deform the plastic sheet by what is called the positive pressure process. It is also known as the blow forming process as it resembles the blow moulding technique often seen with glass. Advantages of using positive pressure, instead of a vacuum, revolve round the availability of high pressure of about 3 atm to 4 atm. To apply pressure a hole is drilled at the top section of the mould, to remove the trapped air inside the mould, vent holes are provided at the bottom of the mould.

Positive and Negative Mould

Positive moulds are convex shaped with plastic sheets deformed over the shape of the mould. Negative moulds are concave shape moulds where the plastic sheet is deformed against the concave shape of the mould. Negative moulds can use any type of pressure whereas positive moulds need negative pressure. During manufacturing if a positive mould is used, the final product will have inner surface dimensions the same as the mould. If a negative mould is used then the outer surface of the final product will have same dimensions as the mould.

Mechanical Thermoforming

Mechanical thermoforming is a third process variation where negative and positive moulds are used together to press the heated plastic sheet. Air pressure/vacuum are not used in this process, rather the mould parts are pressed on both sides of a plastic sheet to force it into the mould shape.

Economics of the Process

As with any commercial process, the pros and cons are often outweighed by the commercial cost. So when it comes to thermoforming the economics are as follows:-

- High production rate of between 60 pieces and 360 pieces per hour possible. Process is only suitable for high production rate and high volume

- Typical lead time is in days

- Process can be fully automated for very high production quantities

- A single machine can use multiple moulds for high production rate

- Depending upon the complexity of the product the tooling costs can start relatively low

- Simple machine costs can be low or moderate but automated machines are very expensive

- Depending on the product and volume the labour cost can be low or moderate

Advantages of Thermoforming

Now we get down to the bottom line, the advantages of thermoforming and exactly what it has to offer for an array of commercial processes:-

- Process produces excellent surface finish but finish is dependent on mould surface condition

- There are no parting lines – this make it unique and better, compared to many other plastic manufacturing processes

- Usually there is minimal (if any) work required once the process is completed

- Thin film manufacturing is possible with a variety of materials – application is usually in industrial packaging items

Disadvantages of Thermoforming

To balance this review of thermoforming we also need to take a look at the disadvantages of the process which are:-

- Material utilization is not good – in the best case it is moderate but can be low

- There can be significant wastage

- The required sheet plastic material is much more expensive than the raw pellet form

- Process can produce excessive sheet thinning at sharp corners

- There are a lot of parameters to consider such as temperature, vacuum pressure and clamping force

Search for articles and topics on Wevolver

Tags