Merlin Engine (Merlin-1D) - Falcon 9 & Falcon Heavy

Gimbaled engines use LOX/RP-1 turbopump gas-generator design for reusable rockets.

Technical Specifications

| MERLIN – SEA LEVEL | |

| Throat Area | 0.042 m2 |

| Nozzle Area | 0.90 m2 |

| Engine Type | Liquid, gas generator |

| Model | Merlin-1D++ |

| Propellant | LOX / RP-1 |

| Propellant Mix | 2.36 |

| Propellant Feed System | Turbopump |

| Thrust (Sea Level) | 854 kN / 190,000 lbf |

| Specific Impulse | 283 sec |

| Chamber Pressure | 10.8 MPa |

| Throttle Capability | Yes (100% to 57%) |

| Restart Capability | Yes |

| Nozzles | Gimbaled, 16:1 expansion |

| MERLIN – VACUUM | |

| Throat Area | 0.042 m2 |

| Nozzle Area | 4.90 m2 |

| Engine Type | Liquid, gas generator |

| Model | Merlin-1DV+ |

| Propellant | LOX / RP-1 |

| Propellant Mix | 2.38 |

| Propellant Feed System | Turbopump |

| Thrust (vacuum) | 981 kN / 220,500 lbf |

| Specific Impulse (vacuum) | 348 sec |

| Throttle Capability | Yes (100% to 64%) |

| Restart Capability | Yes |

| Nozzles | Gimbaled, 165:1 expansion |

Overview

Overview

The Merlin rocket engines are specifically developed for recovery and reuse features of the Falcon series of launch vehicles. These engines are gimbaled and have throttle and restart capability for high degrees of control. Two of the nine Merlin engines in the first stage of the Falcon 9 can malfunction without affecting the launch. Merlin engines utilize cooled rocket-grade kerosene (RP-1) and chilled liquid oxygen as rocket propellants in a gas-generator power cycle. A Turbopump feed system feeds the propellant, heated helium pressurizes the fuel tank. and dual redundant triethylaluminum-triethylborane (TEA-TEB) pyrophoric igniters for restart reliability.

The current active models are Merlin 1D (M1D) for sea-level and Merlin 1D Vac (MVac) for vacuum. These engines have a thrust of 854 kilonewtons at sea level and 981 kilonewtons in a vacuum, respectively. It has the highest thrust-to-weight ratio of approximately 200:1. The Merlin 1D features increased reliability by increasing fatigue life and improving chamber and nozzle thermal margins. It is also easier to manufacture by decreasing the parts count and labor hours.

Problem / Solution

Space is an expensive business. NASA’s space shuttles and Russia’s Soyuz rockets cost an average of $1.6 billion and $53-$225 million for every launch, respectively. However, using reusable booster rockets significantly reduces the expenses for spaceflight.

Since conventional engine designs are not suited for reusable launch vehicles, the Merlin rocket engines are designed and developed specifically to be used in the Falcon series of launch vehicles. The Merlin engines feature retrograde thrust, gimbaled nozzles to adjust the thrust angle, advanced heat shield, high thrust-to-weight ratio, minimized failure nodes, etc. These factors enable the Merlin to be the most suitable engine for the Falcon launch vehicles.

Design

Engine control

Each Merlin engine is assigned one processing unit, which employs three computers constantly checking on the others to instantiate a fault-tolerant design called a triple-redundant system.

Gas generator

Merlin engines utilize cooled rocket-grade kerosene (RP-1) and chilled liquid oxygen (LOX) as rocket propellants in an open-cycle or gas-generator power cycle instead of a staged combustion cycle. A gas-generator cycle burns some of the fuels to generate exhaust gasses that power the pumps, then expelled to the atmosphere or vacuum.

Turbopump

The engine’s propellants are supplied by a single-shaft, dual-impeller turbopump with a pintle-type injector, which provides inherent combustion stability. The Merlin LOX/RP-1 turbopump spins at 36,000 RPM, and produces 10,000 horsepower or 7,500 kW. The turbopump design supplies the hydraulic actuators with high-pressure fluid, which is recycled back into the low-pressure inlet. Thus, a separate hydraulic drive system is not needed.

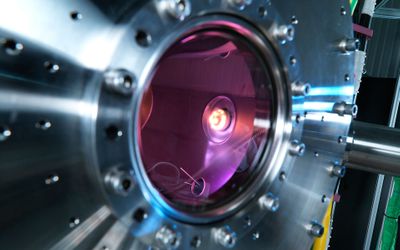

Nozzle

The Sea Level Merlin engines used in the second stage have a smaller exhaust section and 16:1 expansion nozzle primarily for ascent from Earth. The Vacuum Merlin engine used in the second stage has a bigger exhaust section and a larger expansion nozzle of 165:1 to maximize efficiency in the vacuum. The combustion chamber is cooled by regenerative cooling, while the expansion nozzle is by radiative cooling. The nozzle and thrust chamber are lined with a milled copper alloy to provide large heat flux margins.