ScioSense UFM-01 Ultrasonic Flow Sensing Module

Contactless Ultrasonic flow sensor for water flow measurement

Technical Specifications

| Product Type | Ultrasonic Flow Sensor |

| Sensing Range | Up to 2000 l/h |

| Sensing Accuracy | 5% for 60 to 2000 l/h and 10% for 10 to 60 l/h |

| Operating Current | Up to 3mA |

| Communication Interface | Single Wire and UART |

| Operating Voltage | 4.5 to 5.5 Vdc |

| Water Temperature Range | 1 to 60 Degrees Celsius |

| Applications | Smart taps, Faucets, Water Purifiers, Brewing Machines, Coffee Machines, Smart homes and building |

Overview

The ScioSense UFM-01 is a comprehensive sensing unit featuring a 5-pin connector, spool piece, serial communication module, and ultrasonic sensing mechanism. It features a standard BSP ½” thread for instant mounting on water lines. The sensor transmits water flow measurement readings to an external computer or microcontroller via a single-wire and/or UART communication protocol. Unlike traditional Hall-sensor-based flow sensors, the ScioSense UFM-01 doesn’t have any moving parts. It’s a contactless sensor that serves a wide range of applications for flow measurement systems including smart taps, brewing machines, boilers, etc.

Contactless Ultrasonic Technology for High Accuracy Flow Sensing

The contactless mechanism is a unique element that separates the UFM-01 from conventional flow sensors. There are no moving parts such as rotors or actuators, so there is no risk of water contamination. Moreover, it reduces the potential wear and tear in the sensing mechanism, improving the longevity of the device.

It operates on the time-of-flight principle, measuring the duration of the travelling ultrasonic pulse to calculate water flow. Due to the very precise time measurement in picoseconds the calculation of the flow is very accurate in a wide range.. Moreover, easy installation and simplistic hardware design make it a convenient option for low-maintenance systems.

Built-In Temperature Measurement for Control and Monitoring

In addition to flow sensing, the ScioSense UFM-01 Ultrasonic flow sensor features a built-in temperature measurement to monitor liquid temperature. It seamlessly integrates with control systems for temperature feedback.

Hence, it makes the sensor module useful for brewing machines and flow monitoring systems that require temperature control.

Reliable Data Acquisition with Serial Communication Protocol

The UFM-01 Ultrasonic flow sensor is designed to work for longevity. It’s a low-maintenance device offering reliable communication and sensing accuracy of up to 5%. With a simplistic serial connectivity module, it easily transfers sensing data to external microcontrollers and PCs.

The UART protocol offers a baud rate of 2400 bits per second and a capacity of 8 data bits.

The 1-wire protocol works by receiving the reading time sequence and sending out the measurement data.

Designed with Food-Grade Material to Facilitate Wide-Ranging Applications

UFM-01 is designed with food-grade materials. So, it can directly be used with drinking water and hence finds applications in water purifiers, boilers, and coffee machines. Among the major applications of this sensor, the following stand out:

Home Automation with Water Meters: Modern static water meters have no moving parts so the Ultrasonic time-of-flight approach allows smooth and accurate measurement of water flow due to the very precise time measurement in picoseconds.

Smart Taps and Faucets: The flow sensors can improve water consumption by integrating with smart taps and faucets, limiting water flow and detecting potential leakages. It improves the overall system efficiency and helps in water preservation for enhanced resource optimization.

Where to find it

ScioSense

Sensing tomorrow’s world

References

Recommended Specs

Continue Reading

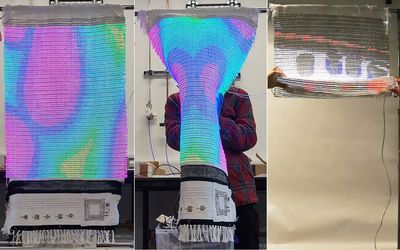

A flexible, foldable, highly-integrated "smart fabric" could herald the future of the cuddlier Internet of Things

Featuring "fiber devices" including a large-format display, temperature and ultraviolet sensors, a touch-sensitive input matrix, and even a heart-rate monitor, this foldable fabric is being positioned as a breakthrough for smart homes and the IoT.

A Smart Home of the Near Future with 1,000 Sensors to Monitor Residents Anytime, Anywhere, Anticipating Their Needs.

The "smart home" is a near future housing concept that utilizes advanced information processing technologies to improve the efficiency and prosperity of life.