Trinckle Fixturemate

Web-based software for designing custom 3D-printed fixtures in under 20 minutes, suitable

Technical Specifications

| Product Type | Software-as-a-Service (SaaS) |

| Description | Enables users to design 3D models of fixtures for additive manufacturing |

| Main Benefits | Easy fixture design for CAD & non-CAD experts, Speeds up repetitive design tasks |

| Deployment Options | Cloud-based (default), On-premises (optional) |

| Underlying Platform | paramate, trCAD |

| GUI Operation | Running in user's browser as a web application |

| Operating System Independence | Yes |

| Ease of Use | No need to install any new software |

| Session Data Separation | 3D geometry data separated from other sessions' data |

Overview

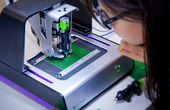

Fixture design in CAD software is time-consuming, even for experienced engineers. Fixturemate is an intuitive web-based software from Trinckle that allows anyone to design custom fixtures fast, whether you're familiar with CAD or not. The software offers features to subtract complex geometries, define baseplates, incorporate standard components, and generate support structures.

Its integration with 3D printing technology enhances production tooling by reducing development time, keeping control in-house, offering design flexibility, and enabling easy, low-cost replacements. Fixturemate exports files optimized for 3D printing and can also generate assembly PDFs. It is used in the manufacturing industry to create various production aids, including assembly fixtures, welding fixtures, and measuring fixtures.

Fixturemate Features

Fixturemate offers a variety of features to streamline the fixture design process, making it accessible to users with or without prior CAD experience.

Here's a breakdown of some of the key features:

Baseplate Design

The baseplate serves as the foundation upon which the fixture is built. Fixturemate provides users with the flexibility to design custom baseplates or choose from a library of standard clamps and baseplates. This streamlines the design process and eliminates the need to recreate complex geometries from scratch.

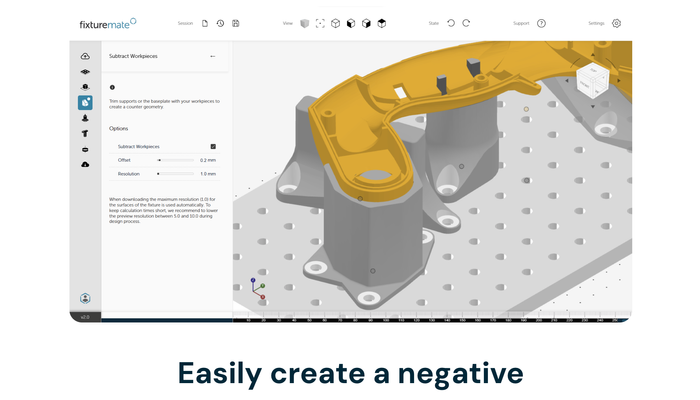

Negative Volume Generation

This feature allows for creating a negative space of the part within the fixture. This is particularly useful for applications like creating moulds or forming sheet metal. In just a few clicks, subtract complex geometries, avoid undercuts, and fine-tune offsets for a securely fitted fixture. The software allows for fine-tuning offsets to ensure a perfect fit between the part and the fixture.

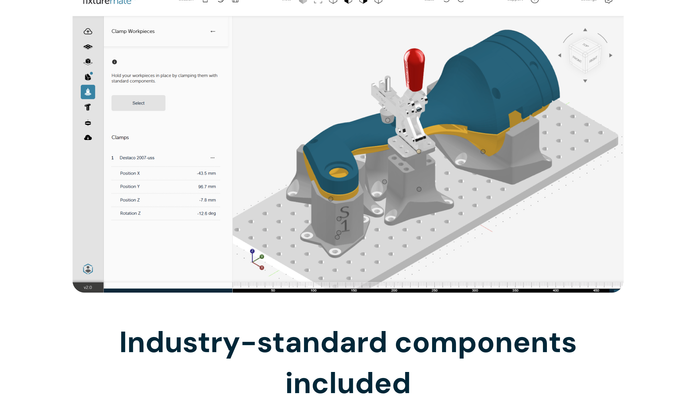

Industry Standard Components Library

Fixturemate includes a library of pre-designed components such as clamps, text labels, holes, and cutouts. These components can be easily incorporated into the fixture design, saving significant time and effort compared to designing them from scratch. This ensures consistency and simplifies the assembly process.

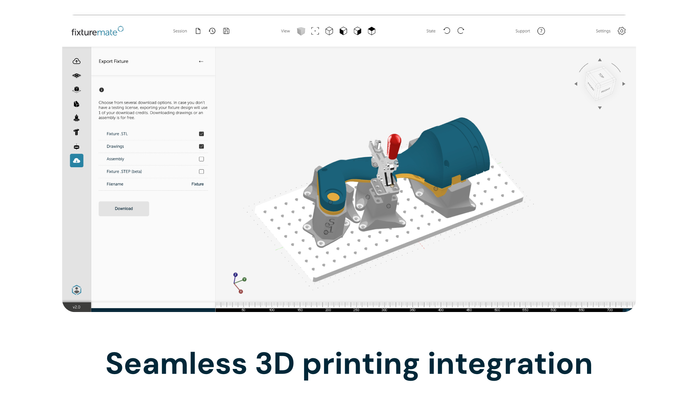

Exporting and Documentation

Fixturemate exports final designs in file formats specifically optimized for 3D printing. Once your design is complete, simply slice, 3D print, and deploy your custom fixture within hours.

For complex fixtures, clear assembly instructions are crucial. Fixturemate automatically generates PDFs with detailed assembly instructions, eliminating the need for manual documentation. This ensures clear communication during the assembly stage.

Design Workflow

Fixturemate outlines a six-step design workflow for creating custom fixtures:

1. Import CAD Data: Upload STL, 3MF, SLDPRT, or STEP workpieces, and position them in the workspace.

2. Define the Baseplate: The fixture's baseplate can be a standard manufactured component, or completely 3D printed. You can design custom baseplates or choose from a library of pre-defined templates.

3. Generate Support Structures: Support workpieces with rectangular, cylindrical, conical, or custom-shaped structures.

4. Create a Negative: Subtract your workpiece geometry from the support structures to form a nested geometry, and fine-tune offsets for a snug fixture fit.

5. Add Standard Components: Incorporate optional features, such as clamps, text labels, holes, or cutouts.

6. Export for 3D Printing: Fixturemate outputs STL files optimized for 3D printing. It can also auto-generate PDFs of 2D drawings to clearly communicate the assembly process.

Applications

Fixturemate is versatile software used across industries to enhance production through 3D-printed tooling. It efficiently designs assembly fixtures for precise part orientation, facilitating easier connections and mounting. Welding fixtures are also crafted to ensure stable and precise alignment during bonding or welding tasks.

For quality control, it creates measuring fixtures that minimize part contact, ensuring accuracy without damage. Inspection gauges from Fixturemate quickly verify part dimensions post-production. Additionally, it supports machining operations with strong, stable fixtures and improves logistics with specially designed carrier trays for safe component transport. Overall, Fixturemate is one software for multiple applications.

References

Recommended Specs

Continue Reading

Engineering Thermoplastics Guide. Chapter 1: Properties and Classification of Engineering Plastic Products

This chapter excerpt introduced an overview of the properties of different classes of thermoplastic materials, with special attention to engineering and advanced thermoplastics.