Tagged with

manufacturing systems

ORGANIZATIONS. SHAPING THE INDUSTRY.

READY Robotics

Robotics & Automation

READY Robotics is a robotics software company that vastly simplifies robot ...

24 Posts

polySpectra

Additive Manufacturing

We help innovative engineers 3D print end-use components they can trust usi...

12 Posts

View more

Latest Posts

Humans sharing a workspace and collaborating with robots has become a reality that companies and their smart factories just can’t do without, as it allows flexible manufacturing in variable batch sizes with maximum efficiency. In short, successful human-machine interaction is key for future-proof manufacturing.

Young Talent Square at Vision, Robotics & Motion 2023: Start-Ups and Student Teams Discuss Their Technologies

Vision, Robotics & Motion is a highly anticipated event in the manufacturing industry that will take place in the Netherlands on the 7th and 8th of June, 2023. It will celebrate its 20th edition in 2023.

Soldering Unveiled: Exploring Wave and Reflow Techniques for Engineering Graduates. Delve into the Depths of PCB Assembly, Component Compatibility, Production Efficiency, and Quality Assurance. Gain Profound Insights into Wave Soldering Machines, Reflow Ovens, and the Art of Soldering. Empower Your Engineering Journey with this In-Depth Comparative Analysis of Two Key Soldering Methods.

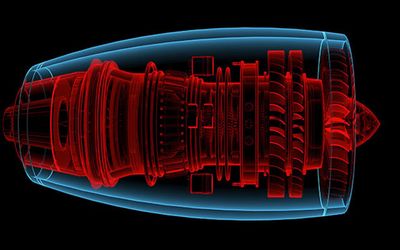

Over the last few decades, reverse engineering has become an essential part of product design and production processes used by manufacturers all over the globe. From aerospace to automotive to everyday consumer goods, industrial engineers and product designers rely on reverse engineering when replicating a legacy part without documentation or drawings, analyzing and deconstructing a competitive product, or modifying and improving an existing one.

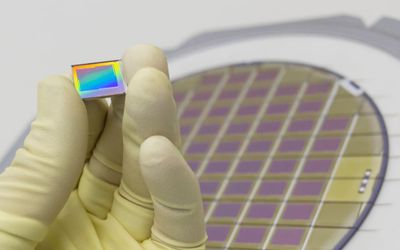

Wafer dicing separates individual integrated circuits or chips from a semiconductor wafer without damaging their delicate structures and circuits. This process is crucial for the production of electronic devices and components used in various industries, and the demand for it has increased with the development of high-performance and smaller electronic devices. Different dicing techniques, such as blade dicing, laser dicing, and plasma dicing, have been developed, and new innovations continue to emerge to address the challenges of complex semiconductor devices.