LOLA

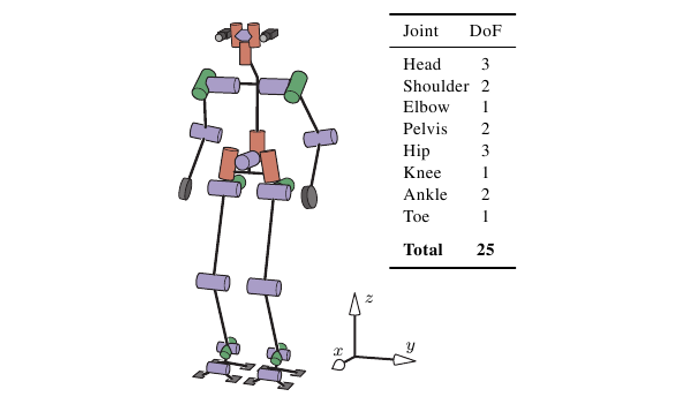

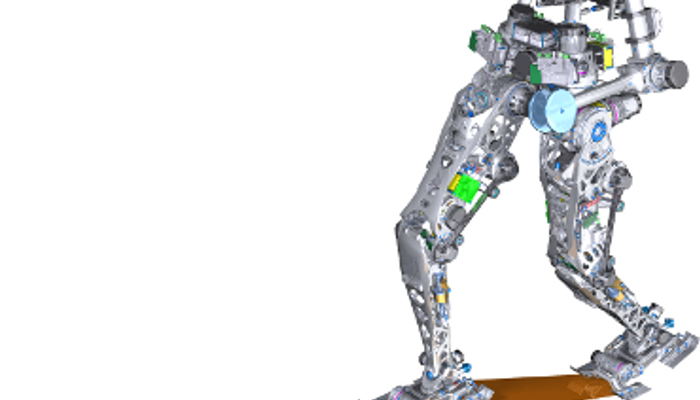

A performance enhanced humanoid that features a modular, multisensory joint design with brushless motors. This prototype can move autonomously indoors thanks to a sophisticated visual recognition system constantly connected to computers and a cable. The robot can avoid obstacles and people in its way in real time. The humanoid robot is 180 cm tall and weighs approximately 55 kg. Its physical dimensions are based on anthropometric data. The characteristics of the robot are the redundant kinematic structure with 7-DoF legs, lightweight construction and a modular joint design using brushless motors. Additional redundant DoFs enable the robot with more natural and flexible walking patterns and extend the abilities of the robot in general. The robot is configured with 25 actuated DoFs: the legs have 7 DoFs each, the pelvis has 2 and each arm 3 DoFs. It has a 3-DoF stereo camera head with pan and tilt axes and adjustable camera convergence angle.

Technical Specifications

| Degrees of freedom | 25 |

| Speed | 5 |

| Height | 180 |

| Weight | 55 |

Overview

This prototype can move autonomously indoors thanks to a sophisticated visual recognition system constantly connected to computers and a cable. The robot can avoid obstacles and people in its way in real time.

The humanoid robot is 180 cm tall and weighs approximately 55 kg. Its physical dimensions are based on anthropometric data. The characteristics of the robot are the redundant kinematic structure with 7-DoF legs, a lightweight construction and a modular joint design using brushless motors.

Additional redundant DoFs enable the robot with more natural and flexible walking patterns and extend the abilities of the robot in general. The robot is configured with 25 actuated DoFs: the legs have 7 DoFs each, the pelvis has 2 and each arm 3 DoFs. It has a 3-DoF stereo camera head with pan and tilt axes and adjustable camera convergence angle.

The robot's weight has a strong influence on the global system dynamics, therefor a lightweight construction is of great importance. Major structural components as investment castings are made from aluminum. Weight and stiffness targets, design proposals are created by topology optimization. Lightness of construction is balanced with the demand for powerful drives necessary in order to achieve the desired torques and speeds at the required bandwidth. Actuator performance is increased carefully, using state-of-the-art motor, gear and sensor technology with high power density.

Control

LOLA is controlled by an on-board PC mounted on the upper body and several local controllers carrying out low-level tasks, such as link position and velocity control, and sensor data processing. Joint controllers, sensors and the on-board PC form an intelligent sensor-actuator network with central controller. The decentral components increase the system's performance from a technological point of view: similar to hierarchical structures in biological systems, sensor data are preprocessed decentrally and only relevant information forwarded to the central controller.

Gait generation and stabilization run on the on-board electronics system without any support from outside except for power supply. An external PC is used only for monitoring purposes and to give basic operating commands if the robot is not connected to the vision system. Because of the high computational demand, image data processing is done on an external PC cluster.

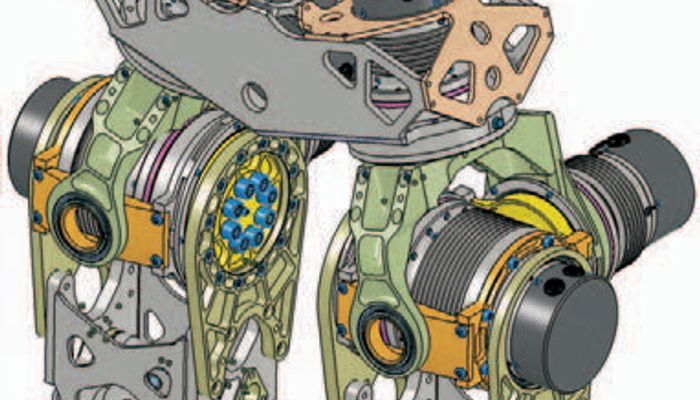

Motor technology

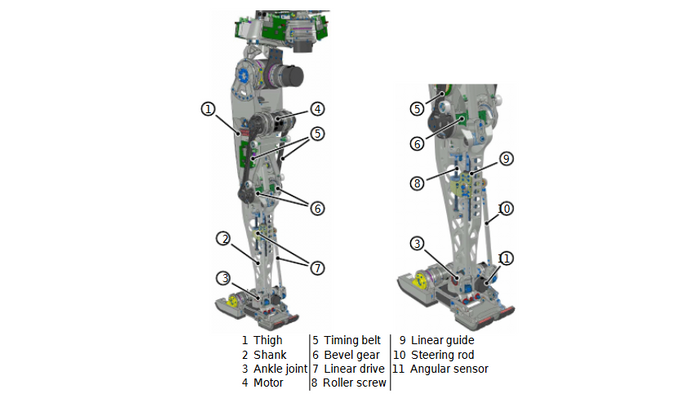

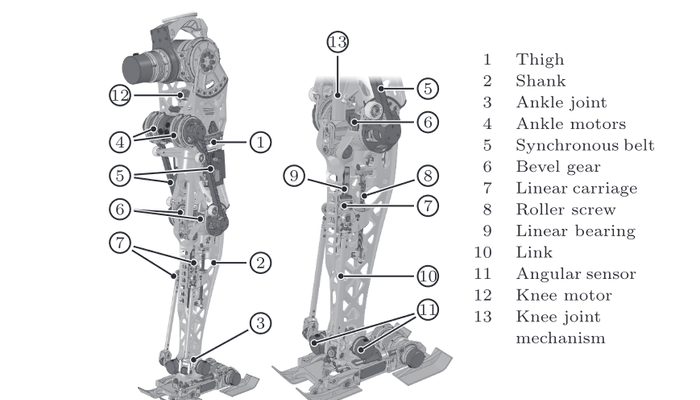

Lola uses permanent magnet synchronous motors (PMSM). These has higher power density copmpared to DC motors, and higher torque and speed bandwidths. PMSM are superior to DC brush motors in both specific peak and continuous torque. Control algorithms and power electronics are more complex because of electronic commutation and three-phase design. PMSM permit larger stall torques for longer intervals than DC motors where mechanical commutation limits stall torque. A special type of PMSM are frameless motors which consist of a stator lamination stack with three-phase winding plus a rotor with permanent magnets bonded onto a ferrous tube.

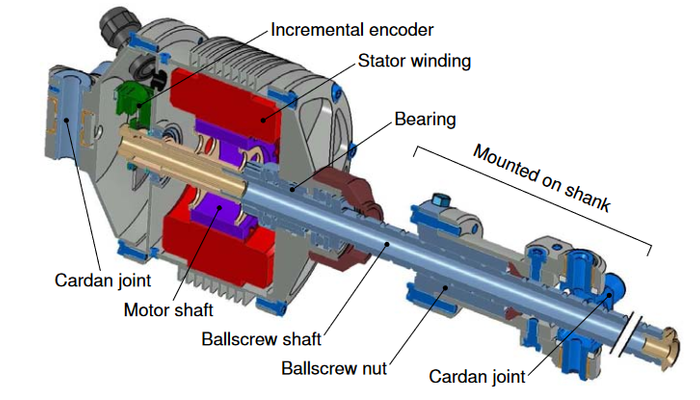

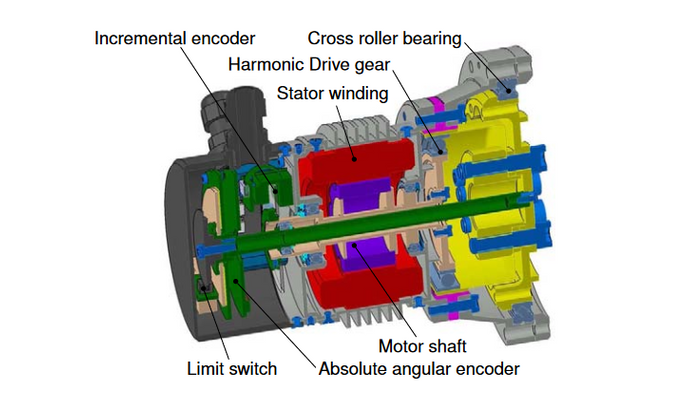

Motor shaft and bearing are customly designed which facilitates a space-saving integration directly into the joint. There is no need for couplings or timing belts, making the whole drive chain free from backlash and slip and, increasing stiffness and system bandwidth. For optimal heat transfer the joint housing has cooling fins and the stator is bonded into the housing with a thermally conductive adhesive. Additional forced ventilation is employed in the highly loaded knee and hip joints.

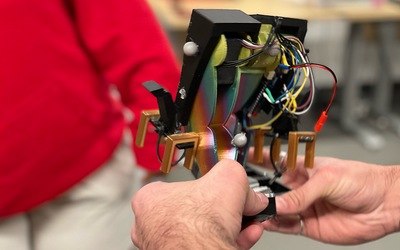

Joint sensors

Each joint contains an incremental rotary encoder, an absolute angular encoder used as link position sensor and a limit switch. The sensors are placed inside the joint housing together with motor and gear, assembled as space-saving as possible.The incremental rotary encoder is mounted on the motor shaft and is mainly used in the field-orientated control algorithm of the motor.

The absolute angular encoder with a resolution of 17 bit compensates elasticities and non linearities in the drive chain and eliminates the need for a homing routine, making startup faster and easier. To improve operational security and to prevent the robot from self-destruction each joint incorporates a limit switch in form of a light barrier. An aperture connected to the output flange determines the angular range of the joint. In case of crossing the allowed angular range, the PWM signals from the DSP to the motor power stage are interrupted without any software interaction.

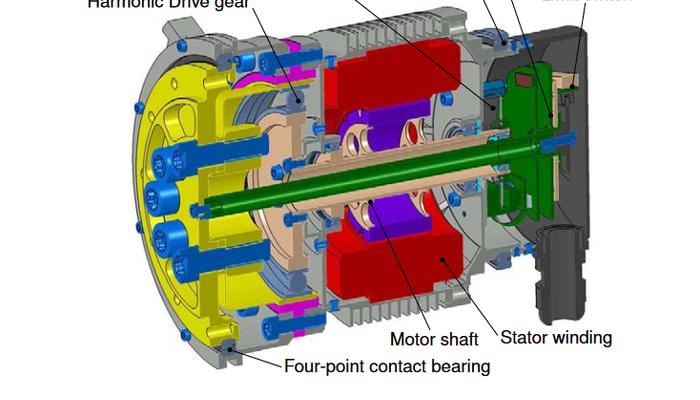

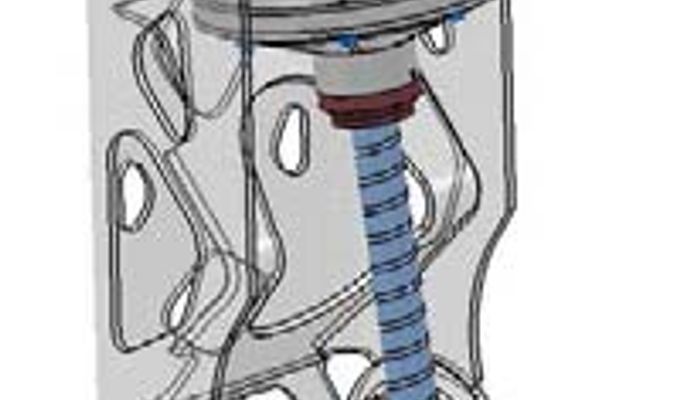

Mechanical design of Harmonic Drive based joints

Most of the robot’s joints are equipped with Harmonic Drivegears as speed reducers. These gears have no-backlash and high reduction ratios on small space at low weight. The compact design of Harmonic Drive component sets allows a space-saving integration directly into the joint units. All gears are custom lightweight versions witha T-shaped Circular Spline which is, in our experience, the best trade off between weight and loading capacity. The Wave Generators, modified for low weight and inertia, are made from aluminum.

The Harmonic Drive CSG series gears which are used in the hip joint pitch axes feature a significant increase in torque capacity in comparison to the standard HFUC series because of improved toothing and Wave Generator bearing. Two joint principles are used which differ in the output flange bearing. Though just one bearing is used, rigidity and high load carrying capability is maintained,space restrictions can be met and the adjacent construction is simplified. Besides a four-point contact bearing of the output flange, the other joint type has a second thrust bearing. This type is used in the hip joint pitch androll axes where a single bearing would unacceptably decreasethe stiffness of the adjacent construction.

References

Describes the design concept of the performance enhanced humanoid robot, but also includes the mechanical design as well as the kinematic structure.

This paper presents different aspects of the complex mechatronic system.

Review of the mechanical design, electronics architecture and sensor system. The architecture of the walking controller, the approach to trajectory generation, walking stabilization and redundancy resolution are discussed. Furthermore experimental results and conclusions are mentioned.

Describes the kinematic structure of the robot, emphasizing the new degrees of freedom. The following section gives a short overview of the dimensioning of the robot hardware including motor and gear selection. Next, the modular joint concept is introduced, followed by a brief overview of the simula

This research includes a real-time walking pattern generator that calculates center of mass trajectories from footstep locations. Key features are the calculation of reference torque patterns by quadratic programming and the solution of the equations of motion by spline collocation. A collocation me

Gives a short overview of the dimensioning of the robot hardware including motor and gear selection. The modular joint concept is introduced. Concludes with the electronics concept using decentralized joint controllers.

Contains the code to control the LOLA robot.

Describes the project, team, acknowledgements, and has extra links to external information.