3D Printed Aluminum: Everything You Need to Know

Though aluminum 3D printing has traditionally been a challenge, big advances have been made in recent years. Here's everything you need to know about aluminum additive manufacturing, from applications and technologies, to what alloys are available.

One of the most common metallic elements on earth, aluminum has been processed as a pure metal in manufacturing since the early 19th century.[1] Today, metal is amongst the most popular in industrial manufacturing, used for objects as common as cans and kitchen utensils, to high-performance components in airplanes and rockets. It is, therefore, no wonder that from its beginnings, the metal additive manufacturing industry was interested in 3D printing aluminum and aluminum alloys.

As we’ll see in more detail, the story of aluminum 3D printing has not been without its challenges, but thanks to innovations on the part of metal materials and hardware developers, aluminum alloys can now be 3D printed using various additive manufacturing processes to create high-quality, lightweight parts for numerous industries.

Applications of 3D Printed Aluminum

There are countless applications for aluminum alloys using 3D printing technologies, but many of the most high-value end-use cases are found in the automotive and aerospace industries. For decades, traditionally manufactured aluminum and aluminum alloys have been used in these industries. In aerospace, for instance, aluminum alloys are used for aircraft wings and fuselage, as well as engine components. In the automotive industry, traditionally manufactured aluminum alloys are used for vehicle bodies, transmission, engine parts, and more. Aluminum has become such a widespread material in these industries—and others—due to its excellent strength-to-weight ratio. It goes without saying that the aerospace and automotive industries are constantly striving to reduce the weight of aircraft and vehicles to improve fuel efficiency—aluminum alloys have enabled them to achieve this while still meeting strength and durability standards.

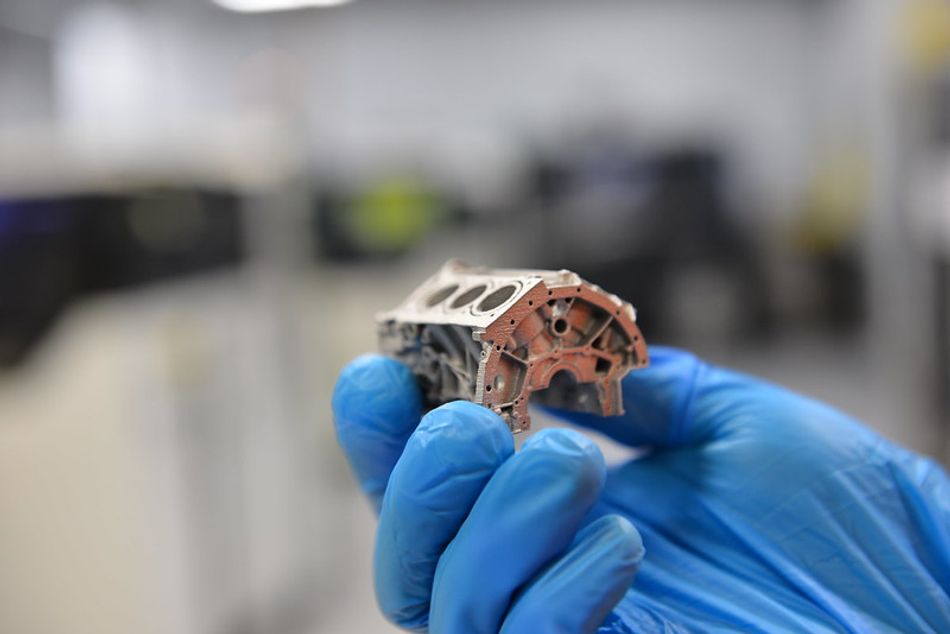

3D printing has opened up even more opportunities in aerospace and automotive for creating efficient parts with low weight. By leveraging intelligent, generative design, engineers can produce optimized components that cut back on weight while maintaining strength. Divergent Technologies, a company that developed a 3D printed supercar, created its own aluminum alloys for 3D printing and has used them to produce safety and suspension components.[2] American automotive giant Ford is working with aluminum AM on an even greater scale: in collaboration with ExOne, Ford is rolling out aluminum binder jetting with the aim of producing high-volume metal parts.[3]

Some of the stronger aluminum alloys with excellent corrosion resistance are finding 3D printing applications in the aerospace industry. Though the material has a lower strength-to-weight ratio than titanium, aluminum is substantially cheaper as a raw material. Used in combination with metal 3D printing technologies, aluminum alloys are used for parts like heat exchangers that benefit from complex geometries and thin, strong walls. In 2021, Boeing demonstrated the successful use of a 3D printed flight critical component made from aluminum—a transmission housing—on a Chinook rotorcraft.[4] Aluminum AM is also being explored and implemented for the production of replacement parts for legacy aircraft.

Of course, aluminum 3D printing is not only being used and explored in the automotive and aerospace industries: it also has applications in the spheres of industrial manufacturing, motorsport, cycling, energy, robotics, jewelry, and beyond. It is also suitable for prototyping and tooling.

Advantages and Disadvantages of 3D Printed Aluminum

Advantages

There are many reasons why demand and interest for aluminum 3D printing have grown in recent years. First, aluminum alloys offer beneficial material properties that meet the needs of many applications. For example, aluminum is lightweight compared to steel and nickel-based alloys, while still providing sufficient strength and hardness. Aluminum alloys also offer good thermal properties as well as corrosion resistance.

3D printing, for its part, brings many advantages to the table compared to traditional manufacturing processes like CNC machining and sheet metal forming. Chief among these advantages is greater design freedom. Engineers and product designers can design aluminum parts with complex geometries, including lattices and internal channels, to optimize the performance and weight of production parts.

Metal 3D printing technologies such as laser powder bed fusion, directed energy deposition, and binder jetting also allow for greater production agility. Specifically, users can speed up turnaround times for part development (by iterating, testing, and tweaking designs), can produce small or one-off production runs, as well as achieve mass customization. Depending on the technology, aluminum 3D printing also allows for high-precision and tight tolerances without extensive post-processing. Another important benefit offered by metal 3D printing is part consolidation. Complex assemblies, like heat exchangers, that would typically be made of several different components can be redesigned into a single, more efficient part, cutting down on production and assembly times.

Disadvantages

Naturally, there are also disadvantages to 3D printing aluminum. Depending on the application at hand, there may be better metal alloys than aluminum-based alloys. For instance, titanium alloys offer a better strength-to-weight ratio than aluminum alloys, making them more common in aviation. Aluminum alloys for 3D printing are also not as strong as nickel-based alloys or steel. That being said, aluminum alloys are less expensive than titanium and are more lightweight than steel and nickel-based materials.

Perhaps the biggest disadvantage of 3D printing aluminum is related to its printability. Fortunately, massive strides have been made in recent years: today, there are a variety of high-quality aluminum alloys specifically developed for additive manufacturing. In the earlier days of metal 3D printing, aluminum presented several challenges. Conventional aluminum alloys, such as 6061, 7075, and 2024, did not undergo powder bed fusion processes well due to their reactivity and were prone to cracking. Casting aluminum alloys, such as A357, while easier to print, were slow to process and had inconsistent mechanical properties due to poor melt pool stability and energy absorption.[5] Thankfully, these issues have been overcome or at least mitigated with the creation of specially tailored aluminum alloys as well as better powder quality.

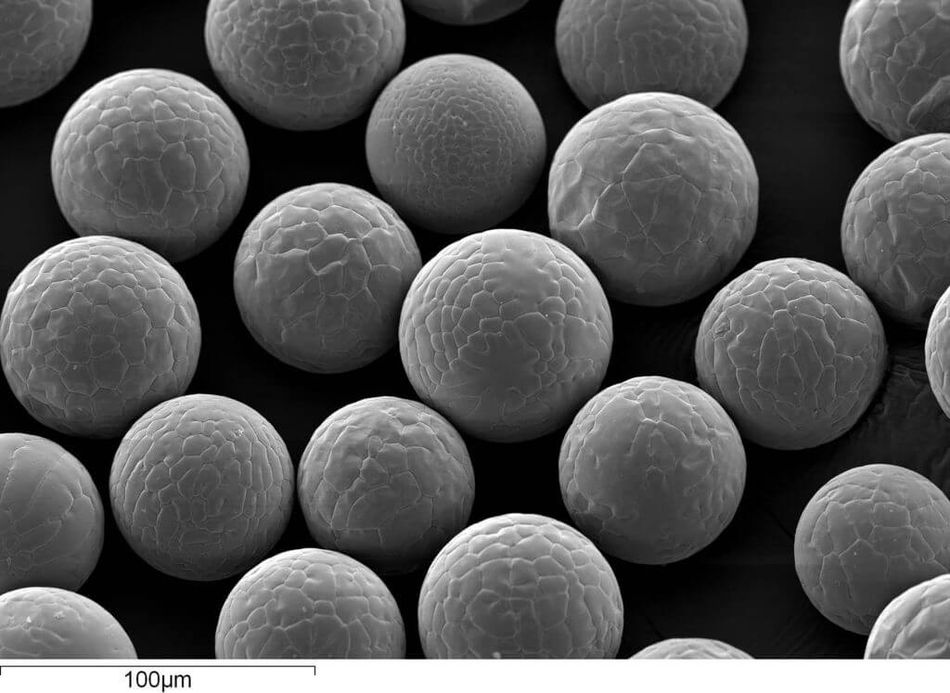

How to 3D Print Aluminum

The first step in 3D printing aluminum is metal powder production. Most aluminum alloy powders on the market today are made using gas atomization. This process is capable of producing powder particles with good sphericity, which is ideal for AM. It should be noted that the characteristics and quality of powder play a big role in how the final 3D printed component turns out. For instance, in laser powder bed fusion processes, sphericity and uniformity lead to better flow and packing, resulting in more reliable prints. Powder particle sizes also range on the micron scale.

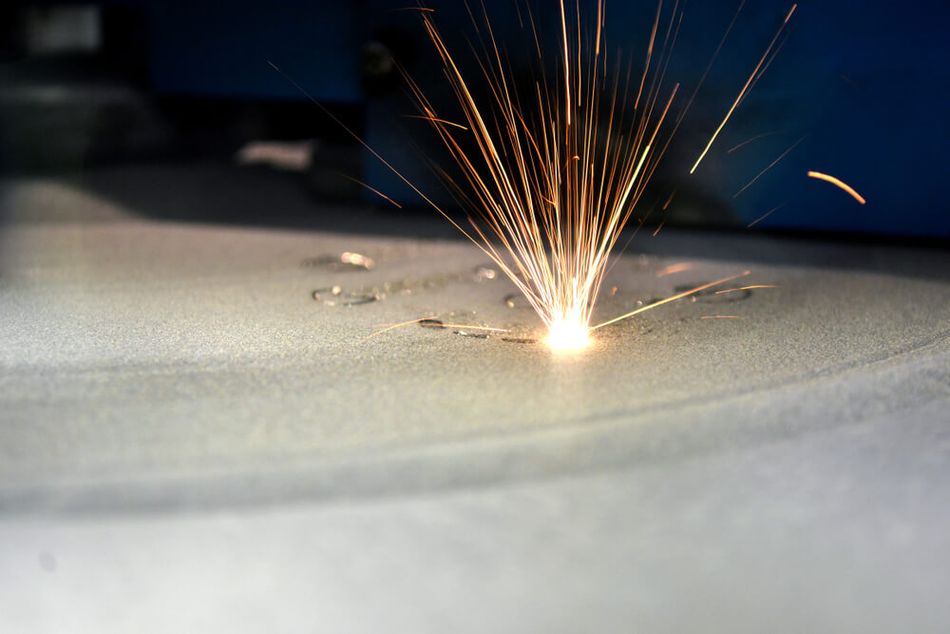

In terms of metal 3D printing technologies available for aluminum prints, there are a few options. The most common 3D printing processes for aluminum alloys are laser powder bed fusion-based including SLM (selective laser melting) and DMLS (direct metal laser sintering). These industrial technologies both rely on a laser energy source to either selectively melt or sinter thin layers of aluminum powder. The powder particles exposed to the laser fuse together and solidify. Once a layer is complete, another coating of aluminum powder is applied and the melting or sintering is repeated. This is continued until a three-dimensional object or series of objects are complete. From there, the parts must be removed from the loose powder and cleaned.

Electron beam melting (EBM) is another PBF process that can print aluminum parts: it uses an electron beam in the 3D printer as an energy source instead of a laser. This process can actually have advantages compared to laser-based technologies, because the electron beam is less affected by the aluminum’s reflectivity, resulting in fewer thermal stresses and less risk of cracking.[6]

Up until recently, binder jetting proved to be challenging for aluminum alloys. The binder jetting process is gaining prominence due to production speed compared to PBF and its capacity to use metal injection molding (MIM) metal powders, which are usually cheaper than AM powders. The problem has been that aluminum alloys have not been widely adapted for MIM in part due to their highly reactive nature. In binder jetting, a binding agent is selectively deposited onto thin layers of a dense metal powder, a process that is repeated layer by layer. The print results in a green part, which must then undergo debinding and sintering. These processes remove the binder and fuse the metal particles together to create a dense final component.

Just in the past year, there have been significant advancements for aluminum binder jetting. ExOne and Ford developed a patent-pending process for binder jetting and sintering aluminum 6061—one of the most commonly used alloys.[3] Ricoh is also developing a binder jetting technology capable of processing aluminum alloys.[7] On the material side, Equispheres is pursuing the development of AlSi10Mg powders specifically tailored to binder jetting.[9]

In addition to powder bed fusion and binder jetting processes, aluminum 3D printing can also be achieved using filament extrusion technologies. Aluminum filaments are made from a combination of metal powders and a polymer matrix. Wire Arc Additive Manufacturing (WAAM) has also been used to produce large-scale structures from aluminum alloys.

Which Aluminum Alloys can be 3D Printed?

Metal powder manufacturers as well as specialized AM powder producers offer a broad range of aluminum alloys for metal 3D printing. These materials are tailored for a range of different uses and applications, offering different properties and profiles. Many of the available aluminum alloys consist of a combination of metallic and metalloid elements, including aluminum, silicon, magnesium, and even copper.

AlSi10Mg is among the most common additive manufacturing aluminum alloys. It is a casting aluminum alloy characterized by good strength, toughness, and corrosion resistance. Many metal AM material providers offer AlSi10Mg. Many other common aluminum alloys for AM, such as F357 (ALSi7Mg) and AlSi12, are casting alloys. These are easier to process than other types of the aluminum alloy due to their relatively low melting point. This class of 3D printing alloy typically contains silicon, which improves the metal’s weldability.

There are also other aluminum alloys for additive manufacturing, which can offer superior properties to casting alloys. For instance, advances are being made to 3D print Al6061, a high-performance hardened aluminum alloy with excellent ductility, thermal conductivity, electrical conductivity, and corrosion resistance. Al7075 is another aluminum alloy that can be 3D printed. The alloy is characterized by its high zinc content and can be heat treated to achieve exceptionally high degrees of strength. Al6061 and Al7075 have traditionally been challenging to 3D print, but thanks to advances in powder quality and the right printing parameters, it is now a possibility.

It is also worth quickly mentioning Scalmalloy, a high-strength metal 3D printing material made from a combination of scandium, aluminum, and magnesium.[8] This material is stronger than traditional aluminum alloys (thanks to the addition of scandium) and offers an excellent strength-to-weight ratio and good ductility. The material is particularly interesting to the aerospace industry.

Conclusion

Aluminum has presented challenges and incredible opportunities for the additive manufacturing industry. Today, we are seeing in real-time how aluminum 3D printing is advancing, with previously “impossible” alloys like 6061 being printed and binder jetting for aluminum alloys finally being realized. All that to say, we are only at the beginning of aluminum AM and are bound to see more amazing applications for the material being developed, from automotive to aerospace and beyond.

References

[1] How Products Are Made, 2022. “Aluminum”. [online] http://www.madehow.com/Volume-5/Aluminum.html [Accessed January 12, 2022]

[2] RDN, 2019. “Divergent, SLM near series production of 3D-printed auto safety, suspension parts”. [online] https://www.repairerdrivennews.com/2019/11/20/divergent-slm-near-series-production-of-3d-printed-auto-safety-suspension-parts/ [Accessed January 12, 2022]

[3] ExOne, 2021. “ExOne and Ford have announced the automotive industry's first binder jet 3D printing and high-density sintering of aluminum”. [online] https://www.exone.com/en-US/Ford-and-ExOne-Achieve-Scientific-Breakthrough [Accessed January 12, 2022]

[4] Boeing, 2021. “Chinook Flies First Flight Critical, 3D-Printed Part on Rotorcraft”. [online] https://www.boeing.com/defense/ch-47-chinook/chinook-flies-first-flight-critical-3d-printed-part-on-rotorcraft.page [Accessed January 12, 2022]

[5] Equispheres, 2021. “Aluminum can be as easy as titanium”. [online] https://equispheres.com/aluminum-can-be-as-easy-as-titanium/ [Accessed January 12, 2022]

[6] Mohammad Saleh Kenevisi, Feng Lin. “Selective electron beam melting of high strength Al2024 alloy; microstructural characterization and mechanical properties”, Journal of Alloys and Compounds, Volume 843, 2020. [online] https://doi.org/10.1016/j.jallcom.2020.155866 [Accessed January 13, 2022]

[7] Ricoh, 2021. “Ricoh introduces aluminium metal binder jetting technology”. [online] https://rapidfab.ricoh-europe.com/ricoh-introduces-aluminium-metal-binder-jetting-technology/ [Accessed January 13, 2022]

[8] Equispheres, 2019. “Sintering Aluminum Alloys With Binder Jet Printer Technology Unfeasible Until Now”. [online] https://equispheres.com/press-release-sintering-aluminum-alloys-with-binder-jet-printer-technology-unfeasible-until-now/ [Accessed January 13, 2022]

[9] APWorks, 2021. “Scalmalloy”. [online] https://www.apworks.de/scalmalloy [Accessed January 13, 2022]