3D Printed Wind Blade Lamination Tool from Recycled Materials

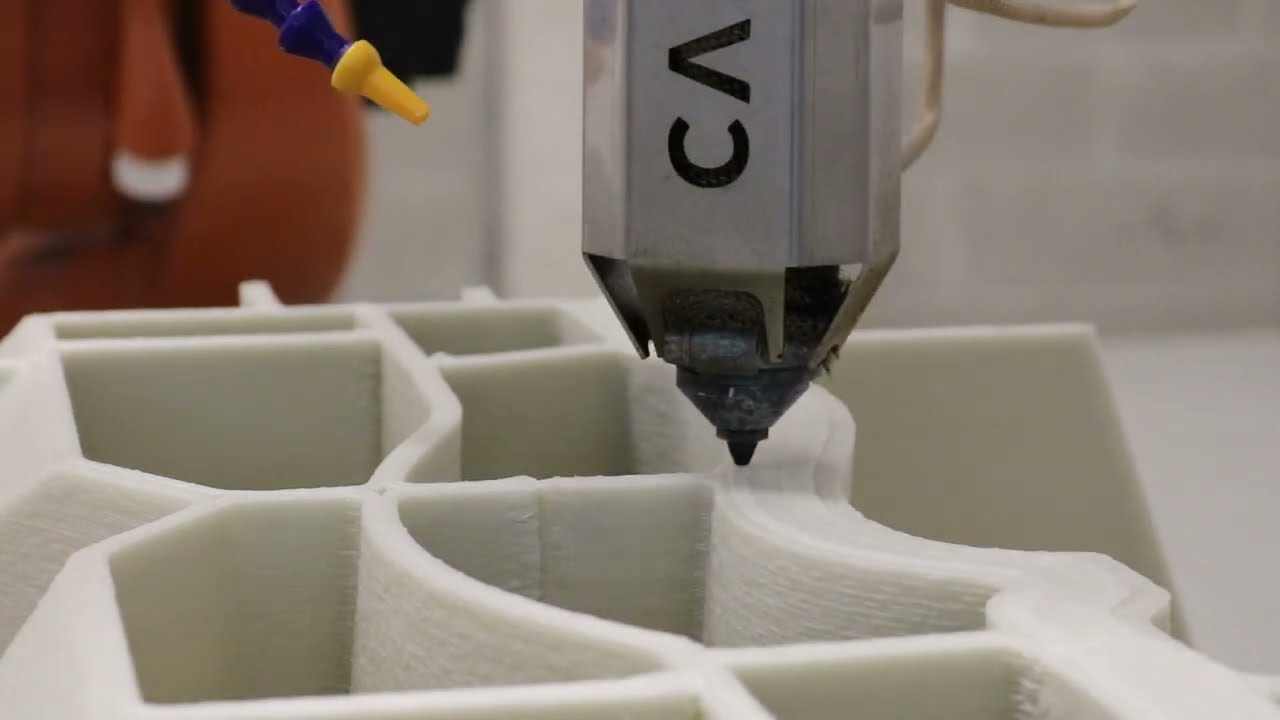

Large Format Additive Manufacturing can be game-changing in product and process optimization, contributing to fighting climate breakdown. For the project Demo4Green - 𝗥𝗔𝗥𝗲-𝗪𝗔𝗦𝗧𝗘, Caracol used recycled glass fibers and polypropylene to produce a lamination tool for micro wind turbines.

Large Format Additive Manufacturing solutions can play a game-changing role in product and process optimization, contributing to fighting climate breakdown. With Caracol's LFAM system Heron AM it was possible to support the ultimate purpose of circular economy, as demonstrated with the research project Demo4Green - 𝗥𝗔𝗥𝗲-𝗪𝗔𝗦𝗧𝗘 “𝗥𝗼𝗯𝗼𝘁𝗶𝗰 𝗟𝗮𝗿𝗴𝗲 𝗙𝗼𝗿𝗺𝗮𝘁 𝗔𝗱𝗱𝗶𝘁𝗶𝘃𝗲 𝗥𝗲𝗺𝗮𝗻𝘂𝗳𝗮𝗰𝘁𝘂𝗿𝗶𝗻𝗴 𝗳𝗿𝗼𝗺 𝗥𝗲𝗰𝘆𝗰𝗹𝗲𝗱 𝗪𝗮𝘀𝘁𝗲”, a project organized by EIT Manufacturing and MADE Competence Center 4.0 in Italy.

Using recycled glass fibers and polypropylene, the company has been working to produce components for the energy sector. The company focused its effort on developing a glass fiber lamination tool for micro wind turbine blades (these turbines are used in urban and rural areas to generate power for factories, offices, buildings, ...).

With its LFAM system HeronAM, Caracol 3D printed a lamination tool for micro wind turbines out of recycled material, achieving and providing evidence of several tangible benefits if compared with traditional processes, such as:

✔️ improved lead time by 50%

✔️ increased raw material saving by 72%

✔️ enhanced waste reduction by 90% compared

The application was validated also from a technical standpoint. The dimensional tolerances and surface roughness of the component were maintained, while the material porosity was equal to a maximum of 0.2 mm.