3D Printer Ventilation: A Comprehensive Guide

3D Printers produce particulates and chemical fumes that can become a health hazard for their users. What are the factors that cause these adversities and how does ventilation help in avoiding them?

3D Printing

Introduction

3D printing has revolutionized the way we approach manufacturing, allowing us to produce complex parts and prototypes with ease and accuracy. However, with the increasing popularity of this technology, it is crucial to understand the importance of proper ventilation when using a 3D printer. The fumes produced during the printing process can be hazardous to human health and the environment, and proper ventilation is essential to minimize these hazards.

In this article, we will delve into the workings of a 3D printer, the types of fumes produced during the printing process, and the importance of proper ventilation. We will also explore the different methods of ventilation, including DIY and commercial solutions, and provide step-by-step instructions for setting up a ventilation system. Additionally, we will discuss the importance of safety measures and maintenance for a ventilation system to ensure the safe and efficient use of a 3D printer.

Whether you are an experienced 3D printing enthusiast or a beginner, this guide is designed to provide a comprehensive understanding of 3D printer ventilation and help you breathe easily while printing.

What is a 3D Printer and How Does it Work?

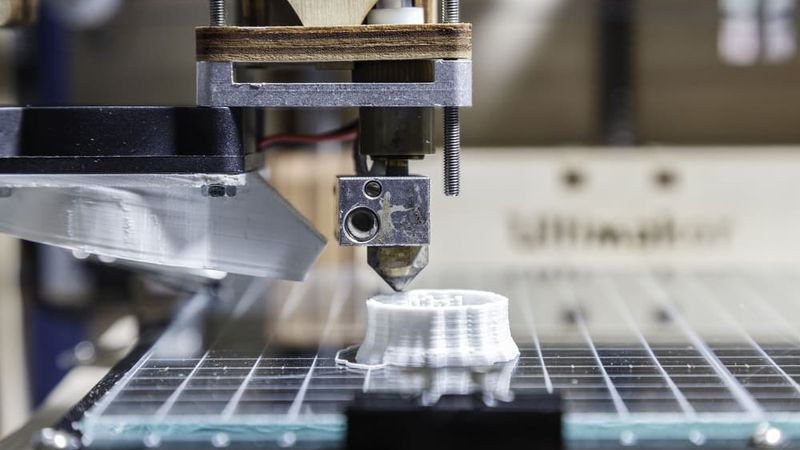

A 3D printer is a machine that creates three-dimensional objects by building up layers of material, such as plastic, resin, or metal. Unlike traditional manufacturing processes that involve cutting and shaping materials, 3D printing allows for the creation of complex and intricate objects with ease.

The basic working mechanism of a 3D printer involves the use of computer-aided design (CAD) software to create a digital model of the object to be printed. The 3D printer reads the digital model and builds the object layer by layer, using a material feed system to deposit the material in the desired shape.

The evolution of 3D printing began in the 1980s with the development of stereolithography, a process that uses ultraviolet light to cure resin into solid objects. Today, there are numerous types of 3D printers available, each with its own unique method of printing and materials that can be used.

The key components of a 3D printer include:

A build platform: This is the surface on which the object is printed.

Extruder: This is the part of the printer that melts the material and deposits it onto the build platform.

Stepper motors: These motors control the movement of the extruder and the build platform.

Control board: This is the brain of the 3D printer, responsible for interpreting the digital model and controlling the movement of the stepper motors.

Understanding the basic working mechanism of a 3D printer is crucial to understanding the importance of proper ventilation when using this technology.

Learn more about 3D Printers and how they work here: How 3D Printers work

Why is Ventilation Important for 3D Printing?

During the 3D printing process, fumes are produced as the filament material is heated and deposited onto the build platform. These fumes contain harmful particles that are released into the environment and can cause nausea, headaches and irritate the eyes and adversely affect the nasal tract. Therefore, proper ventilation is essential to remove such particles from the air and minimize these hazards.

The hazards associated with 3D printing include:

Chemical Vapors: The melting process in 3D printing produces chemical fumes that can be harmful to human health if inhaled. Nylon and other plastic type materials tend to produce VOCs (Volatile Organic Compounds), these compounds contain several harmful chemicals including carcinogens like styrene.

Heat: 3D Printers can reach extreme temperatures during the printing process and can cause other things that come into contact with it to catch fire and cause other safety hazards. Some metals like aluminum and titanium tend to burn quickly and produce dangerous levels of temperature and pressure, requiring extra caution.

Other ultrafine/nano-sized particles: The nano-sized particles can reduce the air quality and can deposit in lungs when inhaled, leading to several breathing problems.

Proper ventilation is therefore important for improving the quality of 3D prints. Proper ventilation helps to reduce the unnecessary emission of chemical fumes, and also to regulate the temperature of the 3D printer and maintain a stable environment, which is crucial for producing high-quality prints.

In conclusion, proper ventilation is essential for the safe and efficient use of a 3D printer. It helps to minimize the hazards associated with 3D printing and improve the quality of the prints produced.

Types of Fumes Produced During 3D Printing

The fumes produced during 3D printing can be classified into two categories: thermoplastic fumes and resin fumes.

Thermoplastic fumes are produced when the plastic material is heated and deposited onto the build platform. These fumes can be composed of both UFPs and VOCs. Ultrafine Particles (UFPs) are very tiny and can cause irritation to the eyes and inflammation in the nasal tract if the users are not equipped with proper safety gear. The term “volatile organic compounds” refers to a broad range of chemicals released through certain liquids and solids. Like PLA, some of them have a nice scent and are not hazardous, while others may be damaging to your health in the short or long term such as styrene, which is used in the production of ABS (Acrylonitrile Butadiene Styrene) and is a known carcinogen.

Resin fumes are produced when printing with photopolymer resins 3D printers, which can be cured when exposed to ultraviolet light. These emitted vapors or fumes include volatile organic compounds (VOCs) such as acrolein, which is a respiratory irritant. Even short-term exposure can cause headaches, throat discomfort, and dizziness.

Check out this article to learn about the risks and appropriate safety measures when dealing with resins: Is UV Resin Toxic? Risks and Safety Measures Explained

The potential health hazards associated with each type of fume vary, and it is important to understand the specific hazards associated with the materials being used for 3D printing. It is also important to note that the fumes produced during 3D printing can vary depending on the type of 3D printer and the materials being used.

The most common fumes produced by 3D printers include:

Styrene: A carcinogen used in the production of ABS

Butanol: Also a carcinogen that can also cause nausea, dizziness, vomiting, etc.

Acrolein: A respiratory irritant used in photopolymer resins

Formaldehyde: A carcinogen used in some photopolymer resins

It is crucial to take the necessary precautions like installing air filters to minimize exposure to these fumes, and proper ventilation is one of the best ways to prevent the harmful effects on the users. By ensuring proper ventilation, you can minimize the potential health hazards associated with 3D printing and create a safe environment for yourself and others.

How to Ventilate a 3D Printer Room

Ventilation is crucial for minimizing the hazards associated with 3D printing and improving the quality of the prints produced. There are several methods of ventilation that can be used in 3D printing, each with its unique benefits and drawbacks.

The different methods of ventilation used in 3D printing include:

Natural ventilation: This method involves opening windows and doors to allow fresh air circulation in the room.

Fan ventilation: This method involves using a fan to remove fumes from the room.

Filtered ventilation: This method involves using a filter or an air purifier to remove harmful fumes from the air. The correct air purifier can assist in removing the particulates and gasses emanating from the 3D printer.

Mechanical ventilation: This method involves using a duct system to remove fumes from the room or directly from the printer enclosure.

Choosing the right method of ventilation will depend on the type of 3D printer and the environment in which it is being used. For example, natural ventilation may not be effective in a small room with limited airflow, while fan ventilation may not be sufficient for removing all of the fumes produced during 3D printing. However, the ideal way to ventilate a 3D printer is using a sealed chamber or enclosure, and then connecting a vent from the chamber to the outside. Similarly, the ideal method for ventilating a resin 3D printer is to construct a negative pressure enclosure that sends air outside. Even though resin fumes don't smell, prolonged exposure to them is harmful.

When setting up a ventilation system for a 3D printer, it is important to consider the following:

The size of the room

The type of 3D printer and the materials being used

The location of the 3D printer in the room

The amount of fresh air available

Here are the steps for setting up a ventilation system for a 3D printer:

Determine the size of the room and the type of 3D printer being used.

Choose the right method of ventilation based on the size of the room, the type of 3D printer, and the amount of fresh air available.

Install the ventilation system, following the manufacturer's instructions.

Regularly maintain and clean the ventilation system to ensure its efficient operation.

By following these steps, you can ensure proper ventilation for your 3D printer and minimize the potential health hazards associated with 3D printing.

How much ventilation does a 3D printer require?

There are several versions of 3D printers that have closed designs that do not require much effort for ventilation. However, compared to their closed box competitors, huge, open 3D printers that are used as professional workhorses and operate continuously undoubtedly need a lot more ventilation. HEPA/VOC filtration-capable enclosures should always be chosen above others. An established lab or student lab with an average of 6 air changes every hour would be a wise idea, especially if the space is already well ventilated, as it is. Additionally, it is always recommended to only use the 3D printers in well-ventilated areas with very little occupancy.

Commercial Ventilation Solutions for 3D Printing

For those who want a hassle-free solution to 3D printer ventilation, there are several commercial ventilation systems available on the market. These systems are designed specifically for 3D printing and offer a range of benefits over DIY solutions.

Here are some of the benefits of commercial ventilation systems for 3D printing:

Ease of use: Commercial ventilation systems are designed for ease of use and require minimal maintenance.

Effectiveness: Commercial ventilation systems are designed to effectively remove fumes and maintain a safe environment for 3D printing.

Customizability: Commercial ventilation systems are available in different sizes and can be customized to meet the specific needs of the user.

When choosing a commercial ventilation system for 3D printing, it is important to consider the following:

The size of the room

The type of 3D printer and the materials being used

The budget

Some popular commercial ventilation systems for 3D printing include:

Industrial Air Filter Systems: This is a high pressure cabin system that uses a H13/H14 grade HEPA filter to remove fumes and particles from the air. The system is also equipped with an automatic pressure control kit for better ventilation.

Air Managers: This filtration system uses a combination of filters and fans to remove fumes from the room. An example is the Air Manager solution for Ultimaker S5.

Air Manager for Ultimaker S5

Air Manager for Ultimaker S5

3D Printing Enclosures: The idea is to build a sealed chamber or an enclosure for the printer to contain the fumes produced during the 3D printing process.

By choosing a commercial ventilation system, you can ensure proper ventilation for your 3D printer and minimize the potential health hazards associated with 3D printing. These systems are designed to provide a safe and efficient environment for 3D printing, making it easy for users to focus on their projects without worrying about ventilation.

Popular 3D printer enclosure ventilation systems

Some of the widely used enclosure systems that are available in the market are:

FUNGDO: It is a multifunctional 3D printer enclosure kit, which is basically a dust cover and waterproof enclosed tent with fume extractor attached to it. It also ventilates resin smell and acts as a temperature regulator. It is available on amazon in 3 different options.

COMGROW: It is a fire-proof and dust-proof enclosure tent lined with PVC laminated polyester for constant temperature control. It is specifically designed for the ENDER series.

UNIDO: It is a fire-proof aluminum and polycarbonate based enclosure kit for constant temperature control. UNIDO is also designed to house the ENDER 3 series 3D printers with a build size of 20.5x24.5x28.8 inches. It is available in two different variants on amazon.

Aaaspark: This 3D printer enclosure system uses stainless steelkeel with threaded connection. It has a durable build that helps stabilize the temperature and also provides noise reduction. It is available on amazon in a build size of 19.6x23.6x28.3 inches.

Maintenance and Upkeep of Ventilation Systems for 3D Printing

Proper maintenance and upkeep of ventilation systems are crucial for ensuring their efficient operation and minimizing the potential health hazards associated with 3D printing. Regardless of whether you have chosen a DIY solution or a commercial ventilation system, it is important to regularly maintain and clean your ventilation system to ensure its proper operation.

Here are some tips for maintaining and cleaning your ventilation system for 3D printing:

Clean the filters regularly: Filters are an essential component of a ventilation system, and it is important to regularly clean them to ensure their efficient operation.

Inspect the ventilation system regularly: Regular inspections can help to identify any potential issues with the ventilation system and prevent them from becoming bigger problems.

Replace worn or damaged components: Over time, components of the ventilation system may become worn or damaged, and it is important to replace them to ensure the efficient operation of the system.

By following these tips, you can ensure that your ventilation system is operating at its best and minimizing the potential health hazards associated with 3D printing. Regular maintenance and upkeep are essential for ensuring the safe and efficient use of a 3D printer.

Safety Measures for 3D Printing with Proper Ventilation

Proper ventilation is essential for minimizing the potential health hazards associated with 3D printing, but it is not the only safety measure that should be taken. To ensure the safe and efficient use of a 3D printer, it is important to follow a range of safety measures in addition to proper ventilation.

Here are some safety measures to consider when 3D printing with proper ventilation:

Wear protective gear: When 3D printing, it is important to wear protective gear such as gloves, eye protection, and a mask to minimize exposure to fumes and heat.

Keep the 3D printer in a well-ventilated room: 3D printers should be placed in a well-ventilated room to minimize exposure to fumes.

Regularly maintain and clean the 3D printer: Regular maintenance and cleaning of the 3D printer can help to ensure its efficient operation and minimize the potential health hazards associated with 3D printing.

Follow the manufacturer's instructions: When using a 3D printer, it is important to follow the manufacturer's instructions to ensure its safe and efficient operation.

By following these safety measures, you can minimize the potential health hazards associated with 3D printing and ensure the safe and efficient use of a 3D printer. It is important to take the necessary precautions to minimize exposure to fumes and heat, and to regularly maintain and clean the 3D printer to ensure its efficient operation.

Conclusion

In conclusion, proper ventilation is essential for the safe and efficient use of a 3D printer. The fumes produced during 3D printing can be hazardous to human health and the environment, and proper ventilation is crucial for minimizing these hazards. There are several methods of ventilation that can be used in 3D printing, including natural ventilation, fan ventilation, filtered ventilation, and mechanical ventilation. Commercial ventilation systems are also available for those who want a hassle-free solution. The best way to ventilate is a 3D printer enclosure with a ventilation system installed that properly tackles the small particulates which are emitted during the printing process. Also, having carbon filters and a HEPA filter can help tackle the odors and smaller particles from entering the exterior environment.

In addition to proper ventilation, it is important to follow a range of safety measures when 3D printing, including wearing protective gear, keeping the 3D printer in a well-ventilated room, regularly maintaining and cleaning the 3D printer, and following the manufacturer's instructions.

By following these tips, you can ensure proper ventilation and minimize the potential health hazards associated with 3D printing. Whether you are using a DIY solution or a commercial ventilation system, it is important to take the necessary precautions to ensure the safe and efficient use of a 3D printer.

FAQs

Q: What are the potential health hazards associated with 3D printing?

A: The fumes produced during 3D printing can be hazardous to human health if inhaled. These fumes can contain harmful carcinogenic chemicals such as styrene, acrolein, and formaldehyde. Proper ventilation is essential for minimizing these hazards.

Q: Why is proper ventilation important for 3D printing?

A: Proper ventilation is important for 3D printing because it minimizes the hazards associated with the fumes produced during the printing process. It also helps to regulate the temperature of the 3D printer and maintain a stable environment, which is crucial for producing high-quality prints.

Q: What are the different methods of ventilation used in 3D printing?

A: The different methods of ventilation used in 3D printing include natural ventilation, fan ventilation, filtered ventilation, and mechanical ventilation. The right method will depend on the type of 3D printer and the environment in which it is being used.

Q: Are there commercial ventilation solutions available for 3D printing?

A: Yes, there are several commercial ventilation systems available for 3D printing. These systems are designed specifically for 3D printing and offer a range of benefits over DIY solutions, including ease of use, effectiveness, and customizability.

References

1. Ultimate Materials Guide - Tips for 3D Printing with PLA [Internet]. Simplify3D. 2022 [cited 2023 Apr 13]. Available from: https://www.simplify3d.com/resources/materials-guide/pla/#:~:text=Polylactic%20Acid%2C%20commonly%20known%20as

2. Ekaran S. 3D Printer Fumes: Are They Dangerous to Your Health? [Internet]. MUO. 2022 [cited 2023 Apr 12]. Available from: https://www.makeuseof.com/3d-printer-fumes-dangerous-your-health/

3. Dwamena M. How to Ventilate a 3D Printer Properly – Do They Need Ventilation? [Internet]. 3D Printerly. [cited 2023 Apr 13]. Available from: https://3dprinterly.com/how-to-ventilate-a-3d-printer-ventilation-systems/

4. O’Neill B. Is UV resin toxic? Risks and safety measures explained [Internet]. Wevolver. 2022 [cited 2023 Apr 13]. Available from: https://www.wevolver.com/article/is-uv-resin-toxic-risks-and-safety-measures-explained

5. Why You Need an Air Purifier for 3D Printing [Internet]. US Air Purifiers. 2018 [cited 2023 Apr 13]. Available from: https://www.usairpurifiers.com/blog/need-air-purifier-3d-printing/#:~:text=If%20you%20really%20want%20to

6. Ultimaker S5 Air Manager [Internet]. 3DGBIRE. [cited 2023 Apr 14]. Available from: https://3dgbire.com/products/ultimaker-s5-air-manager

7. Amazon. FUNGDO Multifunctional 3D Printer Enclosure kit 3D Printer Tent Fume Extractor Smoker Absorber Ventilate Resin Smell Filament Odor Warmer Filament Dryer Dust Cover Waterproof Reduce Noise(Small): Amazon.com: Industrial & Scientific [Internet]. www.amazon.com. 2023 [cited 2023 Apr 13]. Available from: https://www.amazon.com/FUNGDO-Enclosure-Extractor-Ventilation-Eliminate/dp/B0B24W5QXS?th=1

8. Amazon. Amazon.com: Comgrow 3D Printer Warm Enclosure Fireproof and Dustproof 3D Printer Tent, PVC Laminated Polyester Constant Temperature Protective Cover Room for Ender 3/Ender 3 Pro/Ender 3 V2/Ender 5 Pro : Industrial & Scientific [Internet]. www.amazon.com. 2023 [cited 2023 Apr 13]. Available from: https://www.amazon.com/Comgrow-COMGROW-3D-Printer-Enclosure/dp/B098PSZLRH?th=1

9. Amazon. Amazon.com: UNIDO 3D Printer Enclosure Polycarbonate Kit for Ender 3/3 V2/ 3 PRO-Fireproof & Dustproof Tent Constant Temperature Protective Cover 20.5" D x 24.5" W x 28.8" H : Industrial & Scientific [Internet]. www.amazon.com. 2023 [cited 2023 Apr 13]. Available from: https://www.amazon.com/UNIDO-Polycarbonate-PRO-Fireproof-Temperature-Protective/dp/B0BS3YHK5G?th=1

10. Amazon. Amazon.com: Aaaspark 3D Printer Enclosure,Using Stainless steelkeel, Threaded Connection, Fast and Durable, Efficient Noise Reduction,Stabilizes Temperature, Dust-Proof, (19.6”x23.6” x28.3”) : Industrial & Scientific [Internet]. www.amazon.com. 2023 [cited 2023 Apr 13]. Available from: https://www.amazon.com/Aaaspark-Enclosure-Stabilizes-Temperature-Dust-Proof/dp/B08DTWLTPX

11. Shabbir. 3d Printer Ventilation: Why It’s Important And What To Do [Internet]. makershop.co. 2021 [cited 2023 Apr 13]. Available from: https://makershop.co/3d-printer-ventilation/

Table of Contents

IntroductionWhat is a 3D Printer and How Does it Work?Why is Ventilation Important for 3D Printing?Types of Fumes Produced During 3D PrintingHow to Ventilate a 3D Printer RoomHow much ventilation does a 3D printer require?Commercial Ventilation Solutions for 3D PrintingPopular 3D printer enclosure ventilation systemsMaintenance and Upkeep of Ventilation Systems for 3D PrintingSafety Measures for 3D Printing with Proper VentilationConclusionFAQsReferences