5 Reasons To Use An IoT Framework For Your Connected Devices

Considering a quick IoT solution that will get your product deployed faster? Here’s why you should reconsider.

When entering the connected device market, businesses are looking for IoT solutions that can keep costs manageable, scale effectively with business demands, and keep data secure.

In particular, scaling effectively requires proper consideration for provisioning, configuration, monitoring, and analysis of the connected devices because making the wrong decisions early on can get costly later. Getting scalability right is even more critical for sensors deployed in remote and inaccessible locations.

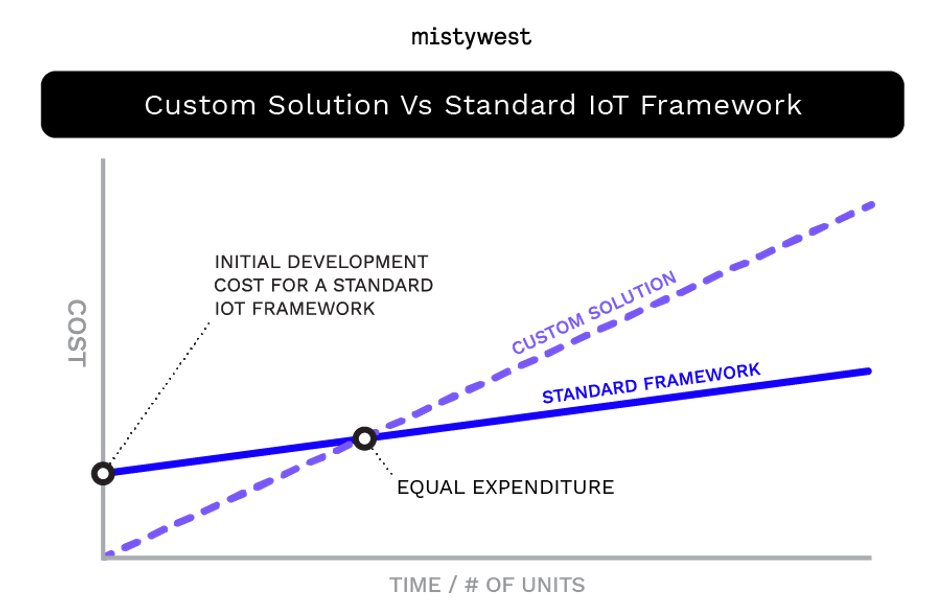

One of our clients initially planned on building their own custom IoT solution for their remote monitored devices that are being deployed in 10 locations. While being a more affordable cost up-front, a custom, in-house solution would require our client to be responsible for all maintenance throughout a device’s lifecycle. This ongoing maintenance would mean increased resources – and increased costs, known as “tech debt”.

Our client ultimately decided on using a standard IoT framework–such as Azure, AWS, or Google Cloud Platform–where they’d pay more for the development up front, but have lower operating costs in the long term. This solution also does not require specialized resources to know the technical systems.

In this post, we look at the 5 major selling features of an IoT framework for a device deployment.

1. Cradle to grave tracking of devices

Our client selected Azure for their IoT framework, using it to provision devices on the assembly line and make a first-time connection. After this, the devices can arrive up-to-date and automatically update to the latest firmware, and any calibration, configuration, or firmware changes are tracked during manufacturing as well as out in the field in an automatic, consistent, cloud-hosted way.

2. Ability to determine at-a-glance whether a device is problematic

Devices dial out to the cloud to establish connectivity, and that connectivity is tracked by Azure’s IoT system. Proactive alerts can be set if a device has not appeared online for a while or data has not been uploaded. All of this automation helps minimize downtime and data loss.

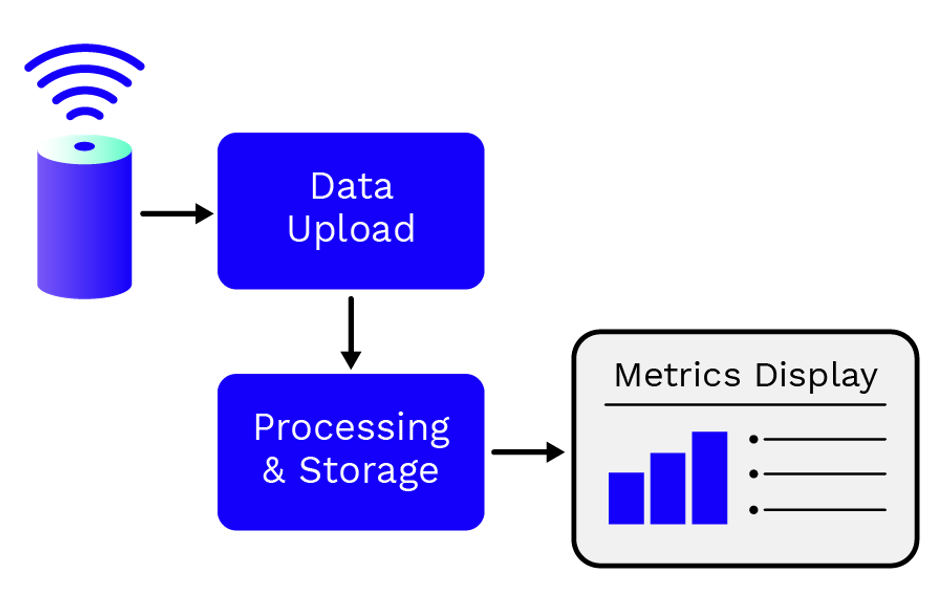

3. Continuous uploading and organization of data

The devices will upload data continuously, whenever there is a connection. The data goes into a standard cloud-hosted storage solution (blob storage) which keeps the data centralized and accessible to those who need it, while also being monitored to ensure the devices are functioning correctly. The data upload can trigger further data processing and automated pipelines that give real time insights into activity.

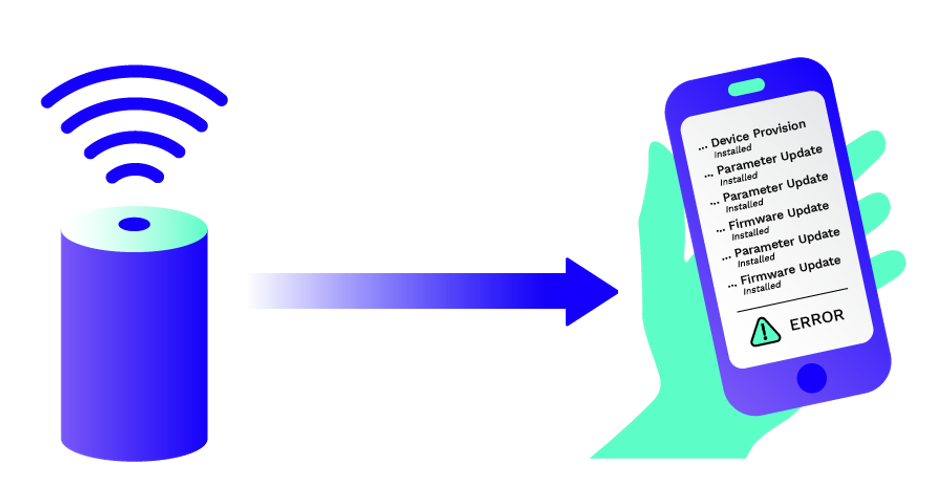

4. Offline (queued) updates to parameters and firmware

Devices on a standard framework don’t have to be online to queue up changes to parameters and schedule new firmware updates – they can be in storage, in transit, or in use. Businesses can adopt a “set it and forget it” mindset knowing updates will be automatically applied. This reduces additional coordination work.

5. Mass updates to the smart device’s parameters

Updates to parameters can be easily made fleet-wide, or to any subset of devices. As the product evolves, these changes can be made to optimize operation, and subsets of devices can be used as a test bed before rolling out changes to a larger number. The built-in optimization for updates helps decrease device management overhead.

Conclusion

When looking at scaling of deployments, the economics favor the standard IoT framework. By using a standard solution you’re leveraging thousands of engineering hours, other companies’ testing, and have the benefit of continued development of new features useful to (and not driven by) your business.

Think about what scale your business is going to be reaching when considering your own connectivity solution – if you plan on continuing to grow, adopting a standard solution will be the more affordable and manageable solution in the long run.

This article was originally written by Kevin Baillie, Mechatronics Designer, for the MistyWest blog.