Biomechanical Marvel-Fluidic Muscle Technology

Advancements in pressurized fluid power systems may hold the key to the next generation of Biomimetic Robots.

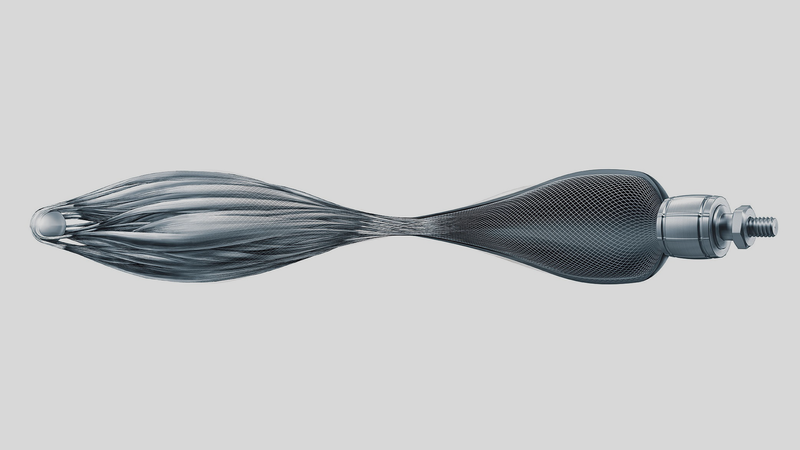

Festo pneumatic muscle actuator promotional image.

This is the second article in the “Biomechanical Marvel” series, exploring artificial muscle technology. Amongst all the artificial muscle actuators currently being developed, the fluidic muscle actuator more closely approximates the resiliency and natural dampening abilities of a biological muscle. This type of technology is nothing new, in fact, some form of fluid technology has been used since ancient times.

So, what does fluidic mean? In this context, fluidic is a term used to describe an actuator or mechanical system that utilizes pneumatic or hydraulic medium to produce controlled movement. Pneumatic/hydraulic technology and devices are all around us. That high-pitched noise you hear when a School Bus or Semi truck parks is due to the pneumatic braking system and of course every time you use your own vehicle brakes, you're employing a hydraulic control system.

Pneumatics vs Hydraulics

The physics behind pressurized fluid power systems is quite interesting. However, it is important to distinguish the two main forms of medium used and their unique properties. Pneumatic systems employ compressed air or inert gases, which are confined within cylinders to transmit force to a piston.

Pneumatic systems can be advantageous due to the compressibility factor of an ideal gas, which enables potential energy storage during the compression process. If you remember from Chemistry class, Robert Boyle, proved experimentally an inverse relationship between pressure and volume of an ideal gas. This relationship allows for an elastic behavior of the gas within the actuator cylinder, which translates into a significant amount of shock absorption throughout the actuation system.

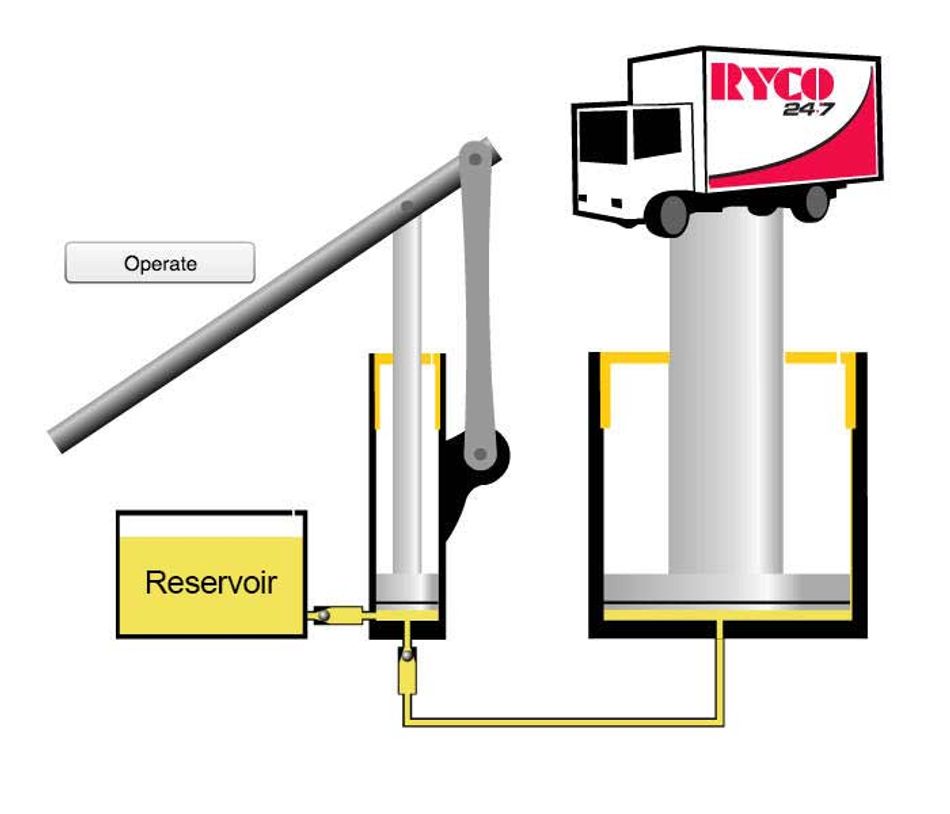

In contrast, hydraulic systems use an incompressible fluid (liquid) medium to multiple and transmit force within a pressurized actuator system. Due to the incompressible nature of liquid, the hydraulic fluid medium exerts precise mechanical force independent of the distance between the force cylinder and the actuator cylinder. This is why a hydraulic system is well suited for a vehicle braking system. The force that you exert on the brake pedal is directly exerted onto the brake calipers, without any elasticity.

Another name you may remember from Chemistry class is Blaise Pascal, a French scientist that discovered the force multiplication ability of hydraulic systems. Analogous to a lever system or “simple machine”, the incompressible fluid can transmit a force of higher magnitude between a smaller cylinder to a larger cylinder, thus generating a mechanical advantage. For example, in an open-loop hydraulic circuit, a “pumping” cylinder is connected to a “lifting” cylinder via high-pressure hoses. With the “pumping” cylinder(C1) having a radius of 5 inches2 and the “lifting” cylinder(C2) having a radius of 50 inches2, the ratio of the surface area of C1 to C2 is 1 to 100, respectively. Therefore, if the force exerted on C1 is 10lbs, the force exerted on C2 will be 1000lbs, thus creating a substantial mechanical advantage.

The Mckibben Air Muscle

The PAM (Pneumatic Artificial Muscle) actuator was developed by, Atomic Physicist, Dr. Joseph Laws Mckibben in the early 1950s. Dr. Mckibben was prompted to invent a soft, robotic actuator that could be used to aid his 13-year-old daughter, Karen. During this time, thousands of children and young adults were stricken with paralysis due to the Polio epidemic of the 1900s. Karen was one of the unfortunate victims of the Poliovirus, which left her paralyzed from the neck down.

The Mckibben air muscle was utilized as a contractile element for a powered, orthopedic brace. The "Active Brace", allowed for controlled movement of paralyzed limbs, which enabled patients to complete simple tasks. It was at this time that the term, "artificial muscle" was coined.

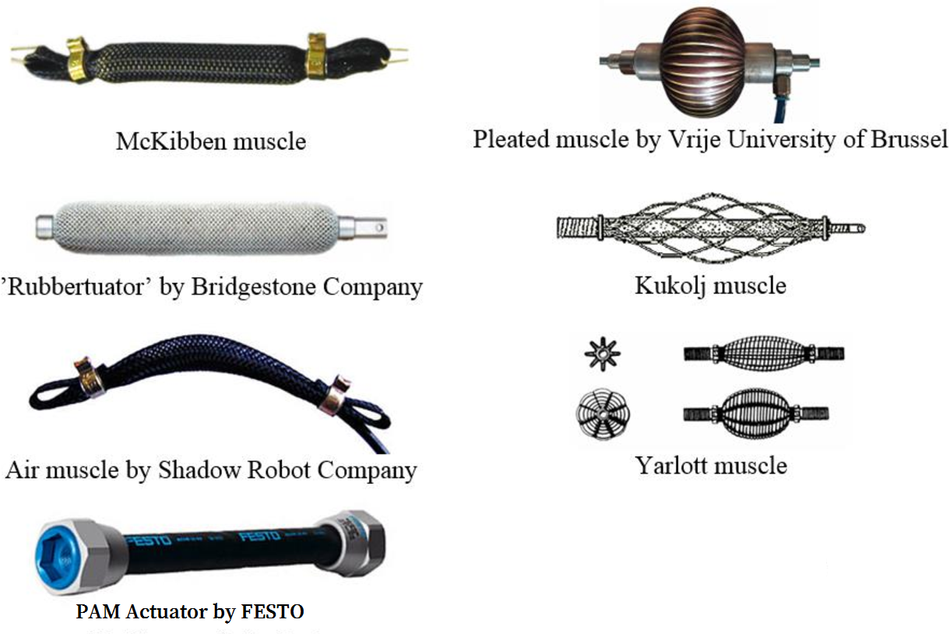

The Mckibben artificial muscle or PAM typically comprises an inner membrane or rubber tube, jacketed within a nylon braided mesh. Metal clamps or fittings are employed to secure the terminal ends of the composite, membrane/braided mesh structure and also serve as anchor points for attachment to a kinematic structure.

Pressurized air is used to inflate the inner membrane, which causes radial expansion and linear contraction of the braided mesh. The resulting linear contraction mimics the morphology of a biological muscle contraction with similar force and velocity, directly dependent upon the magnitude of gauge pressure applied. Additional variables can also contribute to the force of the actuator contraction, including the size of the inner membrane and type of polymeric material used. The braided mesh may also comprise different variations such as; pleated, straight fiber-reinforced and braided reinforced.

Advantages over Conventional Actuators

Due to the simplicity of design and light-weight materials used, PAMs often exhibit high strength to weight ratios. PAMs are capable of producing up to 40lbs of tension force with relatively low air pressure. In addition to substantial force properties, PAMs can activate at high velocities, with a linear displacement percentage of 25%, similar to a biological muscle.

One of the most attractive attributes of PAM technology is the compliance and dampening properties exhibited. Similar to biological muscle and tendon attachments, PAM actuators can exhibit viscoelastic properties. This is an important attribute to have due to the close proximity modern robots will have with humans. Any physical interaction with a PAM actuated robot will be more forgiving in terms of the compliance of movement. A prime example is assistive walking exoskeletons for disabled or elderly patients. The inherent compliance of the PAM actuator will provide a natural dampening effect of misplaced kinetic energy generated while walking with the exoskeleton, in order to avoid further injury to the patient.

Current Limitations

One glaring disadvantage of the PAM actuator is that a constant source of pressurized air is needed for activation. Pressurized air or gas can only be stored in bulky tanks or supplied via an air compressor. This is a reason why PAM actuator technology is not currently used for prosthetic limbs. Accurate control modeling can also be challenging due to the non-linear, force characteristics of PAM based actuators. Mathematical models needed to predict the dynamic change and relationship between linear displacement and force with any given air pressure often contain several unknown parameters. A common starting point to determine the derivative or rate of change at any given point of contraction can be based upon the acceptable operating air pressure range. Accurate control modeling is a necessity for the calibration of PAM actuators in order to provide precise control and longevity of the PAM actuator system.

Variations on a Theme

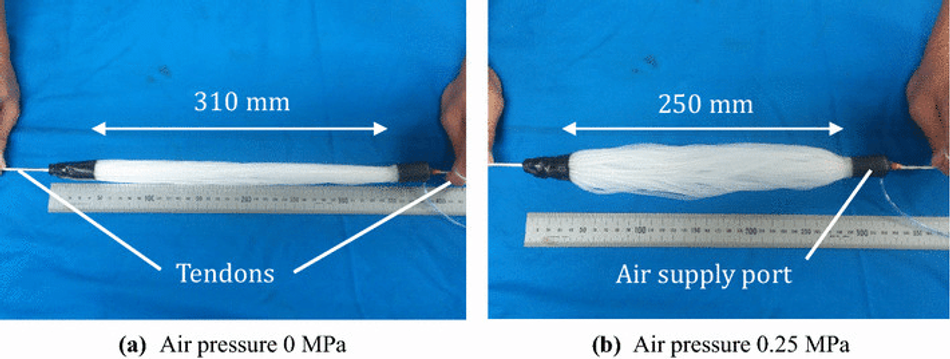

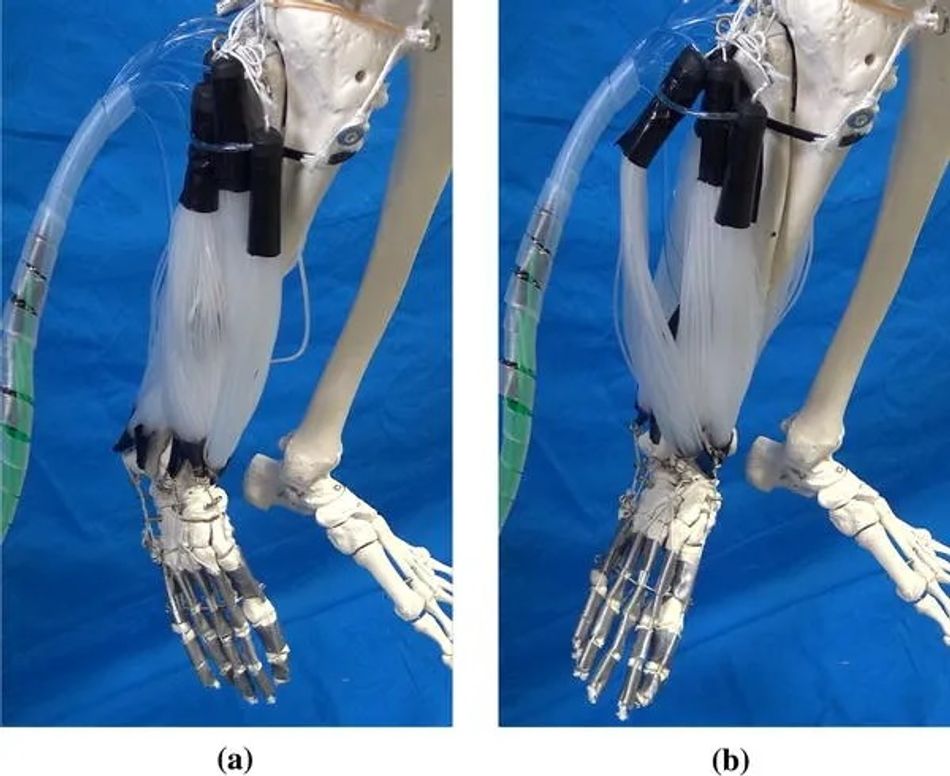

Researchers from the Robotics Society of Japan have developed a “thin” Mckibben actuator, based upon the principles of biological muscle fiber arrangements. Instead of a single, central inner membrane; the multi-filament, bio-inspired actuator, uses an array of thin, polymeric tubes. Each polymeric tube acts as a single muscle fiber, which are bundled together to form an artificial muscle. The research team includes alumni Shunichi Kurumaya, Hiroyuki Nabae, Koichi Suzumori, Shuichi Wakimoto.

FESTO

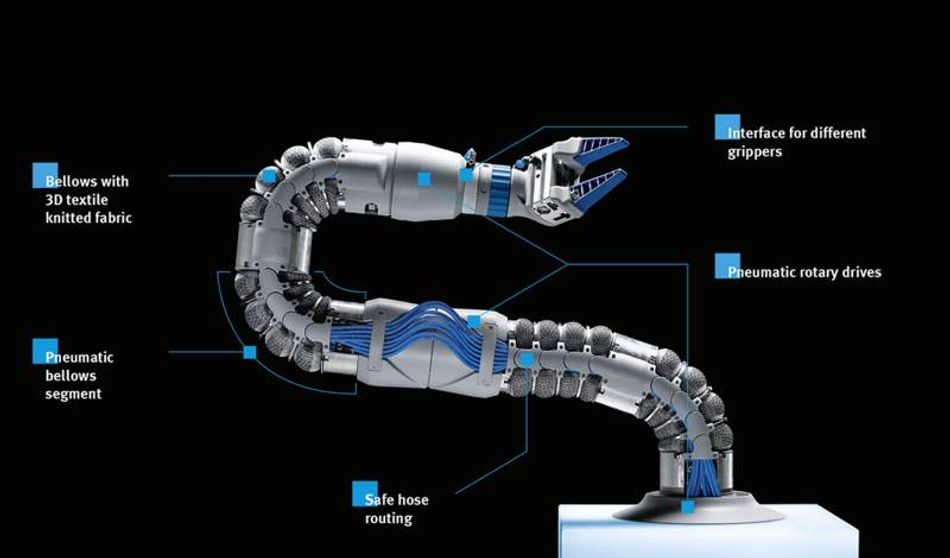

In the realm of PAM based actuators, multinational robotics company, FESTO, has redefined the technology and taken it to the next level. Founded in 1925 by Albert Fezer and Gottlieb Stoll-FESTO has diversified over the decades to include industrial automation, technical education and has conducted intensive biomimetic research, which has lead to a Bionic Learning Network.

Founded in 2006, the Bionic Learning Network(BLN) paradigm includes a core team of in house engineers, designers and biologists; interconnected with several Universities and additional Tech companies. The BLN enables interdisciplinary discussions and an exchange of ideas, overreaching several sectors, in order to develop new technologies and inspire the next generation of scientists.

One of the key technologies employed by FESTO is their proprietary Fluidic Muscle actuator(FMA). The FMA comprises an inner rubber diaphragm, which is surrounded by woven aramid fibers. Aramid is a special class of high strength synthetic fibers, which not only adds structural integrity to the actuator but also transmits kinetic energy. The FMA has been designed to mimic the functionality of a biological muscle for use in complex, industrial automation.

The DMSP model is capable of an actuator frequency response of up to 150 Hz. This is a critical attribute for any actuator, especially for automation of repetitive movements. Basically, the frequency response of an actuator is a measure of how accurate the actuator will respond to input command voltages and the corresponding desired output, over the course of a specified time interval. Typically, the output of the actuator is measured against a standard, sinusoidal test input signal. This method is also advantageous in determining the stability of a closed-loop control system at different frequencies. The FMA has proven to be a reliable actuator solution in several areas of industrial automation.

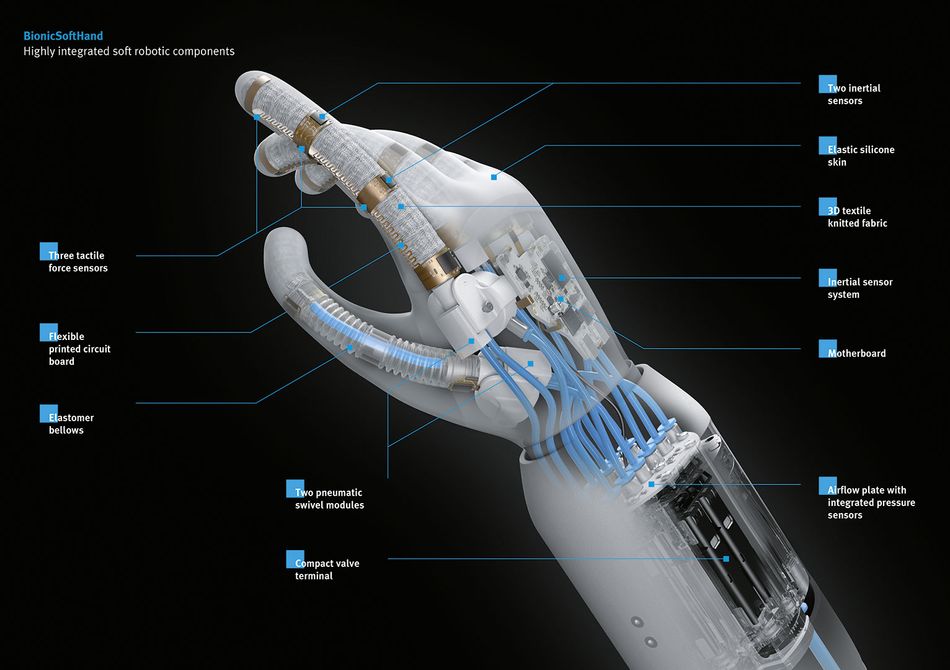

BionicSofthand

In addition to perfecting the Fluidic Muscle actuator, FESTO has made incredible strides towards merging pneumatic control systems with A.I. One of the goals of the Bionic Learning Network is to create robots that not only imitate the movement of biological systems but are also able to learn and adapt to new environments.

With this in mind, the BionicSofthand utilizes a sophisticated A.I. construct known as “Reinforcement Learning”. Instead of following programmed vector movements, the BionicSofthand A.I. is programmed with heuristic algorithms that enable completion of complex tasks through trial and error, based on corresponding positive or negative feedback.

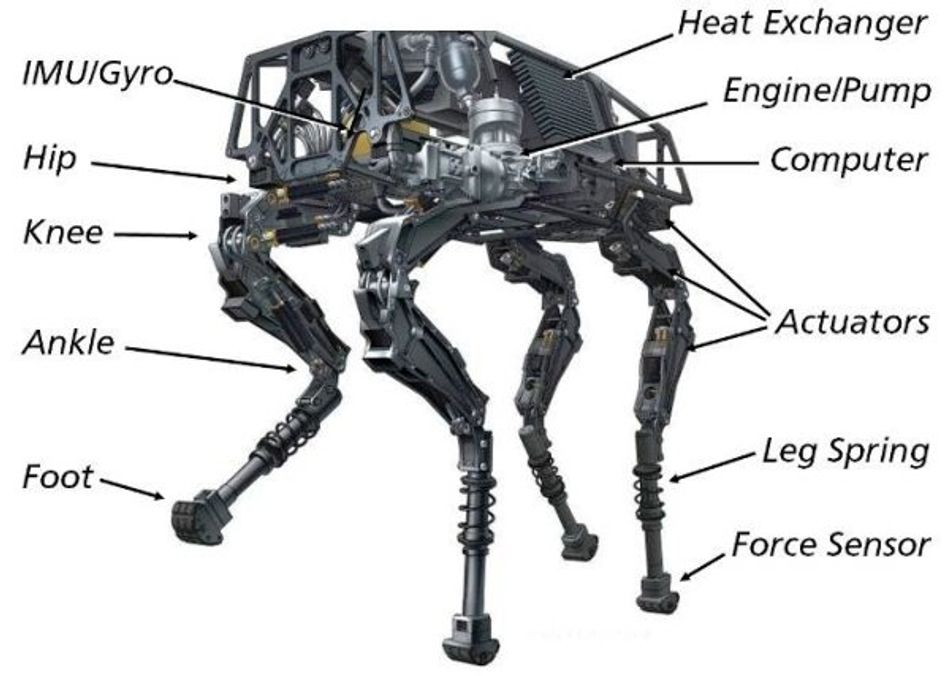

Boston Dynamics

A leader in hydraulic actuator technology, Boston Dynamics, has raised the bar for rugged, autonomous robots. MIT graduate, Dr. Marc Raibert, founded Boston Dynamics in 1992 with the primary goal to create bionic, bipedal and quadrupedal robots. Towards this goal, Dr. Raibert, has worked on developing biomimetic, hydraulic mechanisms and control methods; for which he has been granted several patents. In fact, his novel designs mimic the natural movement of biological systems so well, that many people find his creations downright, uncanny.

Starting in 2005, Boston dynamics, released BigDog-the most agile, dynamically stable, quadrupedal robot, at that time. BigDog was originally designed to be a military carrier robot that would be able to carry heavy supplies and traverse rough terrain alongside soldiers in the field.

Unfortunately, the DARPA funded project was discontinued due to noise concerns. The loud noise in question, was caused by the internal combustion engine used to power the main hydraulic pump. In order to alleviate this problem, an all-electric hydraulic pump was utilized for the next incarnation of quadruped robot, the Spot Classic.

Atlas robot

Towards bipedal research and development, Boston Dynamics created the PETMAN(Protection Ensemble Test Mannequin). The PETMAN enabled testing of hazmat and other hazardous type protection suits for viability in the field without subjecting humans to harm. The PETMAN proved to be capable of dynamic movement, which included squatting, push-ups and walking, while tethered to an external harness.

As the case with any technology, with each new model, the design can be streamlined and improved upon-this is definitely the case with Boston Dynamics', ATLAS. Based upon the PETMAN design, the ATLAS is an incredibly agile, anthropomorphic robot which is capable of working alongside emergency response teams during rescue operations.

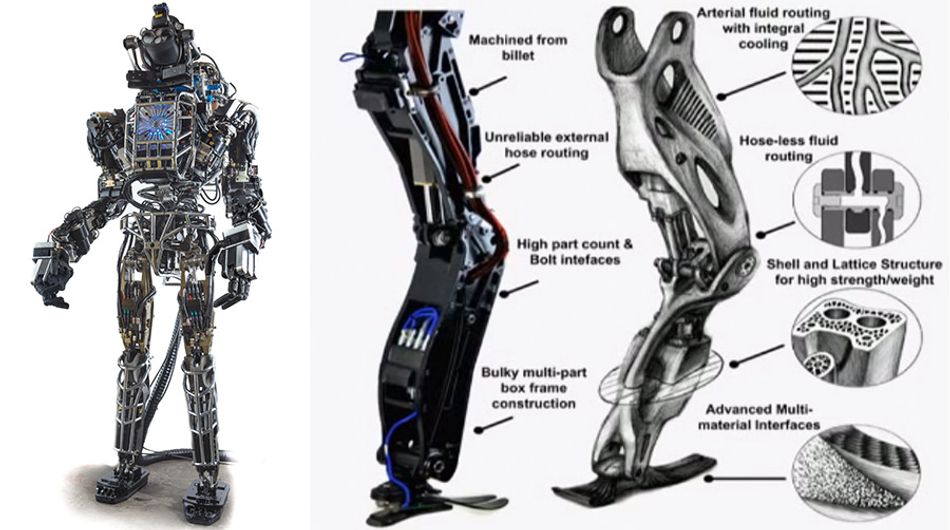

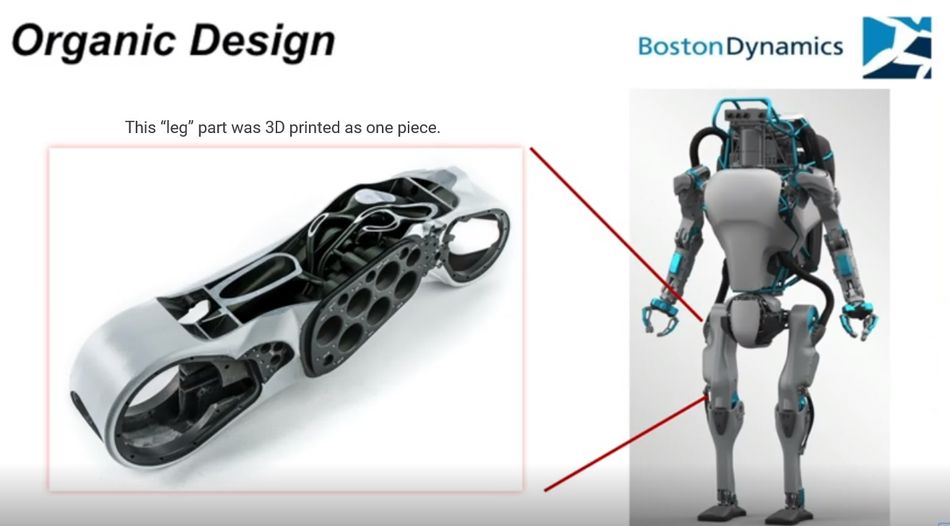

The ATLAS houses over 28 hydraulic joints which are powered by an extremely, compact hydraulic power unit. In addition to a dynamic control system, one of the key technologies that has been instrumental in the construction of ATLAS is 3D printing. Boston Dynamics has utilized 3D printing technologies to create organic structural components with integrated internal mechanisms, that provide high strength to weight ratios. These crucial properties provide ATLAS the strength and agility to work alongside humans in unpredictable environments.

Recent Advancements

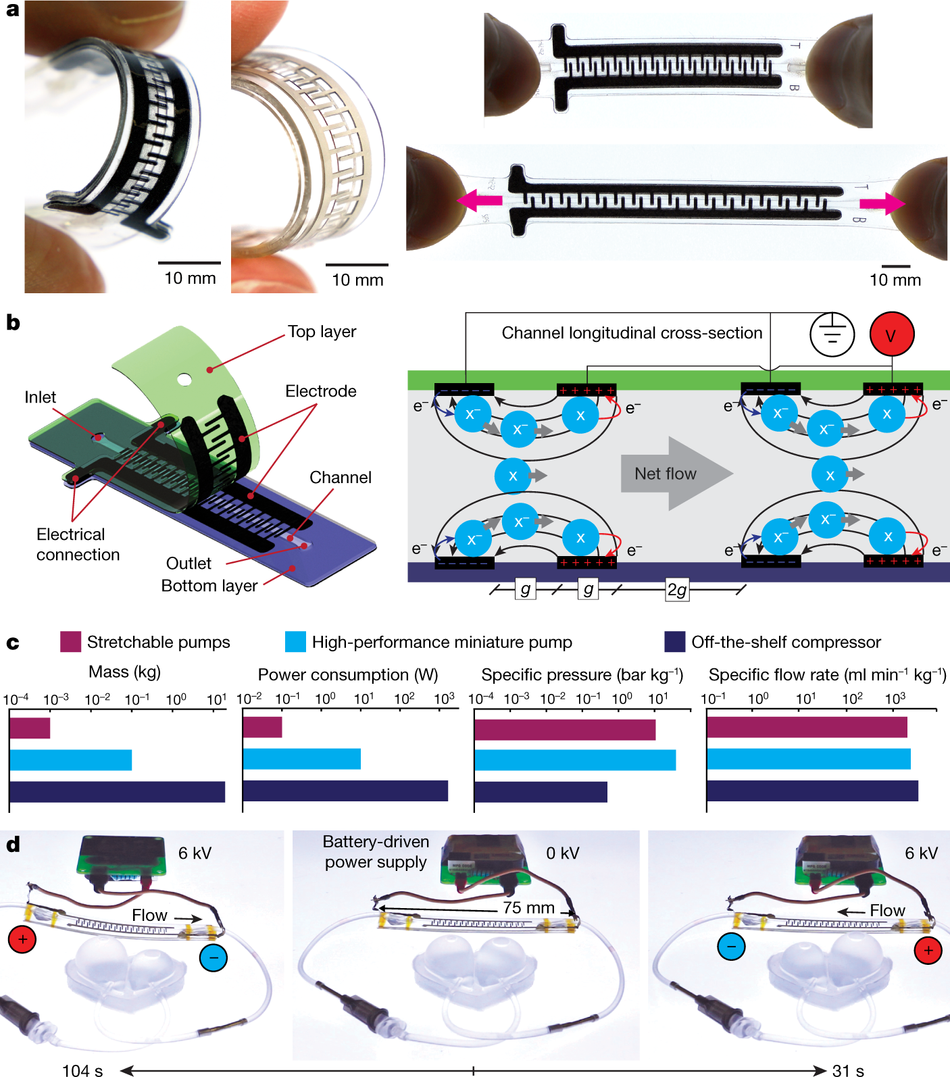

Although PAM technology is based upon using air or gas as a fluid medium, the technology can be operated with hydraulic fluid as well. With the use of different medium comes a change of characteristics, such as rigidity and non-elastic behavior of an incompressible fluid. However, this may be warranted for certain applications. Within this context, Swiss researchers at the Ecole Polytechnique Fédérale de Lausanne have developed a novel, quasi-solid state fluidic pump for use with soft robotics.

The researchers responsible for this innovative soft pump consider it a complete paradigm shift, due to the fact that it eliminates the need for a bulky compressor. The novel soft pumps are created by using semi-conductor fabrication methods, wherein the metallic electrodes are printed on a flexible, polymeric substrate. A dielectric fluid is contained within the soft actuator, with the application of an electric field, the now polarized fluid accelerates within the fluid channel.

This technology opens the door for all types of soft robotics applications. Some of the future projects include pseudo-musculature clothing for augmented strength(Bionic Clothing), soft exoskeletons for rehabilitation and dynamic, body temperature regulating clothing. The Ecole Polytechnique Fédérale de Lausanne research team is currently collaborating with Koichi Suzumori laboratory in Japan to develop artificial muscles based on this technology.

Image of a glove for human augmentation by using stretchable pumps. The glove includes: 1) a thermal regulation circuit where a stretchable pump circulates liquid in thin flexible tubes embedded in the glove’s fabric; 2) two soft fluidic muscles on the index and thumb fingers. These artificial muscles can be used for rehabilitation or to augment the capabilities of the hand’s muscles. Via the EPFL soft tranducers website.

This is the second article in the “Biomechanical Marvel” series, exploring artificial muscle technology. Read the first article "Biomechanical Marvel-Creating An Artificial Muscle Actuator" here.