Electric aviation: Batteries that stay strong for the flight duration

Borrowing methods from biology, a team of scientists and engineers designed and tested an electrolyte that keeps battery power delivery high, cycle after cycle.

Photo by NOAA on Unsplash

This article was first published on

news.engin.umich.eduA battery component innovation could help keep power delivery high when electric aircraft land with low charge, according to a study led by Lawrence Berkeley National Laboratory with expertise from the University of Michigan.

The research provides a solution to a problem identified in 2018 in a study led by Venkat Viswanathan, a professor of aerospace engineering at U-M and a coauthor of the new work published in Joule.

“Both takeoff and landing require high power, and landing is more challenging because you’re not fully charged,” Viswanathan said. “To get high power you have to bring all the resistances down. Anything that affects the ability to deliver that power.”

The team emphasized that this is distinct from the needs of EV batteries, which mainly need to maintain their ranges.

“In an electric vehicle, you focus on capacity fade over time,” said Youngmin Ko, a postdoctoral researcher at Berkeley Lab’s Molecular Foundry and lead author of the Joule study. “But for aircraft, it’s the power fade that’s critical—the ability to consistently achieve high power for takeoff and landing.”

Both capacity fade and power fade typically occur when lithium ions can no longer move easily in and out of the electrodes. While the key for capacity fade is the quantity of lithium ions that can move between the electrodes, the main factor for power fade is speed. The problem is that corrosion builds up on the electrodes, taking up space that could have housed lithium ions and making it harder for the lithium to reach available spaces.

Under the leadership of Brett Helms, corresponding author of the study and a senior staff scientist at Berkeley Lab’s Molecular Foundry, the team explored the interactions among the electrodes and electrolyte using an approach borrowed from biology. In studies of life, the field generally called “omics” looks for clues in the constituents of cells—what genes are being read, what proteins are being made, and so on.

In this case, the team tried different electrolyte chemistries, looking at subtle changes that occurred within the electrolyte at different locations in the battery during charging and discharging. Prior research has typically attributed power fade to problems arising at the battery’s negative side, as lithium metal is very reactive.

However, the team observed that damaging molecules were forming near the positive side—nickel-manganese-cobalt oxide in this case. Reacting with those molecules caused the particles of the positive electrode to crack and corrode over time, hindering the movement of lithium and reducing power delivery.

“It was a non-obvious outcome,” Ko said. “We found that mixing salts in the electrolyte could suppress the reactivity of typically reactive species, which formed a stabilizing, corrosion-resistant coating.”

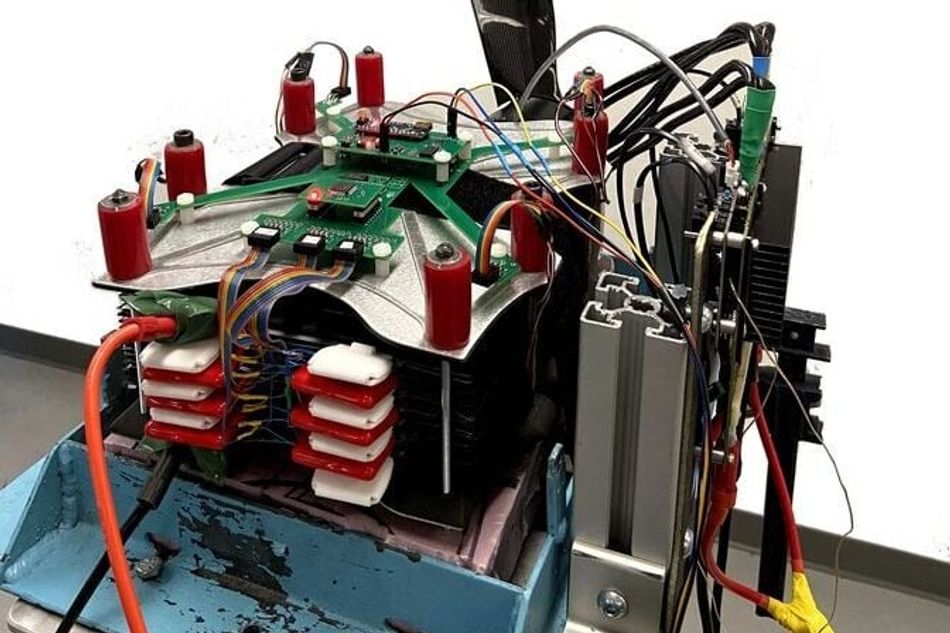

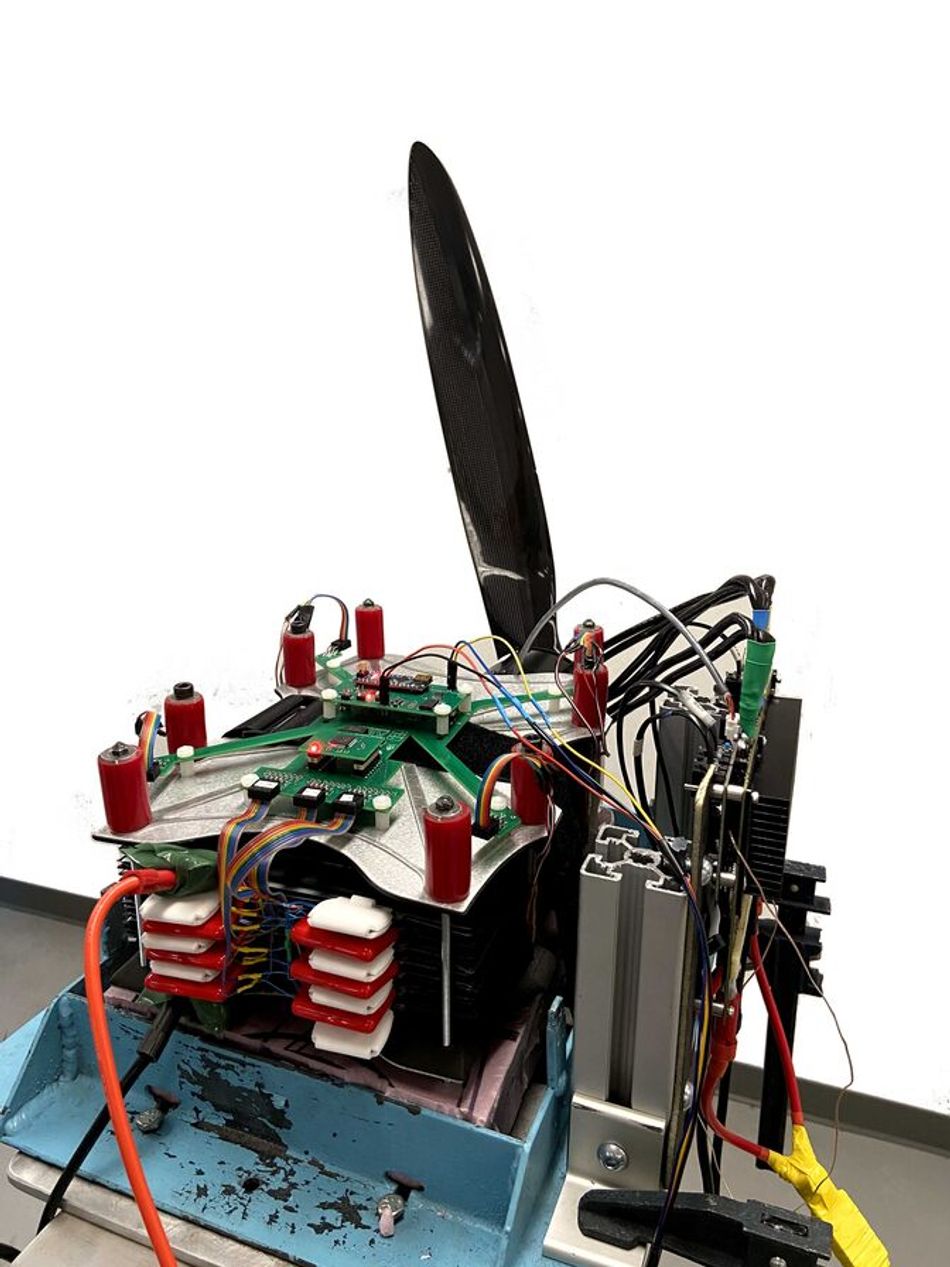

The company 24M (Cambridge, MA), then built a test cell with this chemistry and sent it to And Battery Aero (Palo Alto, CA)—a startup that Viswanathan co-founded with his former PhD student Shashank Sripad, a co-author of this study and the one from 2018.

Sripad tested the cell by repeatedly drawing power from it in a realistic sequence of takeoff, flight and landing, as if the cell were part of a complete battery module powering an electric aircraft. When compared to conventional batteries, the new cell maintained the power-to-energy ratio needed for electric flight for four times longer.

“Heavy transport sectors, including aviation, have been underexplored in terms of electrification,” Helms said. “Our work redefines what’s possible, pushing the boundaries of battery technology to enable deeper decarbonization.”

Next, 24M will build a complete battery that And Battery Aero will test on a propeller stand, running the propeller through the flight sequence repeatedly. Then, next year, the team intends to attempt to perform an electric flight test with those batteries.

The team—which includes scientists at the University of California, Berkeley—also plans to expand the use of omics in battery research, exploring the interactions of various electrolyte components to further understand and tailor the performance of batteries for current and emerging use-cases in transportation and the grid.

The Molecular Foundry is a DOE Office of Science user facility at Berkeley Lab.

This work was supported by DOE’s Advanced Research Projects Agency-Energy (ARPA-E) and DOE’s Office of Science (Basic Energy Sciences).

Viswanathan and Sripad have a financial interest in And Battery Aero.