Elevating Industrial Asset Inspection

The Role of SLAM and 3D Mapping in Modern NDT Inspection Technologies

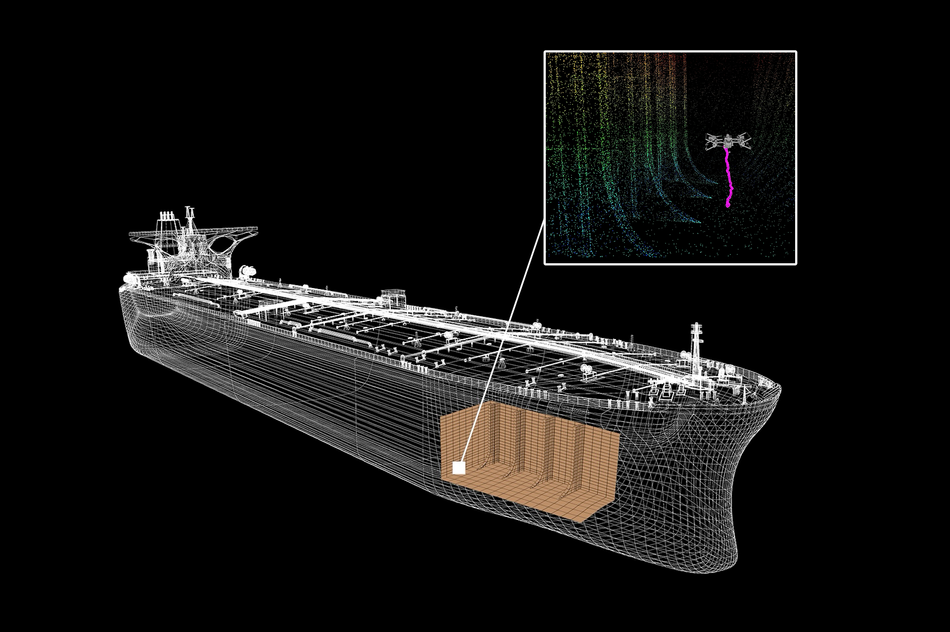

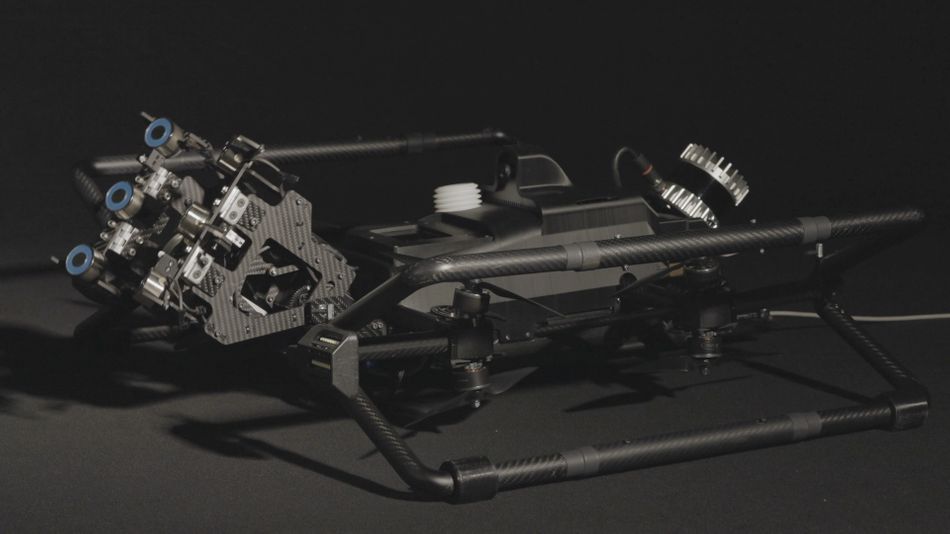

As Non-Destructive Testing (NDT) technology advances, industries like energy, oil and gas, and maritime cargo are demanding more sophisticated, efficient, and safer inspection methods. Traditional approaches may no longer meet the complex requirements of today’s critical infrastructure inspections. Avestec's latest development, SKYRON 2, introduces significant advancements in this area, notably through its use of SLAM (Simultaneous Localization and Mapping) technology and 3D mapping capabilities.

Importance of SLAM and 3D Mapping in Inspection Industries

1. Enhanced Precision and Accuracy

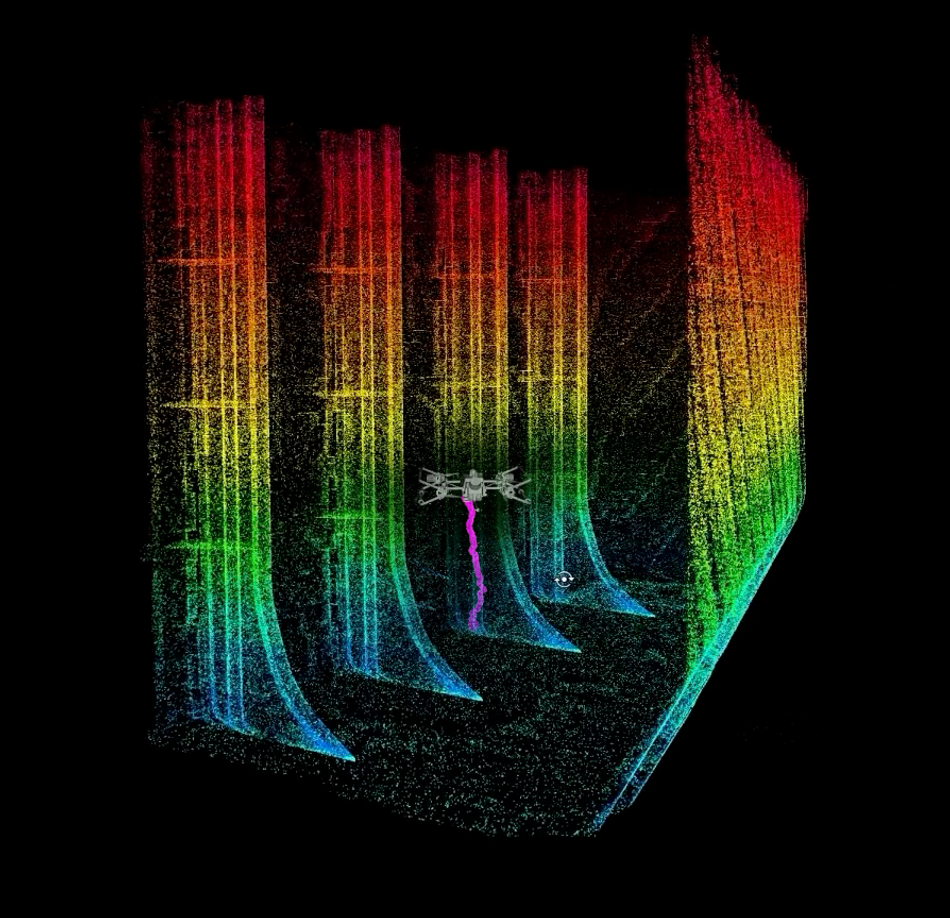

SLAM technology allows robots to generate detailed, real-time 3D maps of their surroundings while concurrently tracking their own position. This capability is essential for high-precision inspections of critical assets such as pipelines, cargo hulls, and FPSOs (Floating Production Storage and Offloading units). Traditional methods often involve manual measurements and visual inspections that can be prone to errors. By integrating SLAM with 3D mapping, SKYRON 2 offers a more accurate and comprehensive view of the asset, minimizing missed defects and improving overall inspection quality.

2. Efficient Data Collection

3D mapping is crucial for efficient data collection, particularly in complex and expansive environments like large oil and gas refineries. With SLAM-equipped tools, inspectors can cover extensive areas and intricate structures more swiftly than with manual methods. This efficiency not only accelerates the inspection process but also reduces downtime for critical assets, thus supporting continuous operations and cost management.

3. Real-Time Navigation and Analysis

Real-time 3D mapping facilitates dynamic navigation and immediate data analysis. SLAM technology provides live updates on the robot’s position and environmental conditions, enabling operators to make informed decisions during inspections. This is particularly advantageous in hazardous or confined spaces where traditional methods might be inadequate. The ability to adapt to real-time conditions and address issues as they arise enhances inspection effectiveness and contributes to better maintenance practices.

4. Safety Enhancements

Safety is a major concern in many inspection environments, especially in high-risk or hard-to-reach areas. SLAM and 3D mapping technologies enable inspectors to operate from a safe distance, reducing the need for direct human involvement in potentially dangerous conditions. Remote-controlled robots equipped with these technologies mitigate risks and ensure inspections can be conducted in areas where human access may be restricted or unsafe.

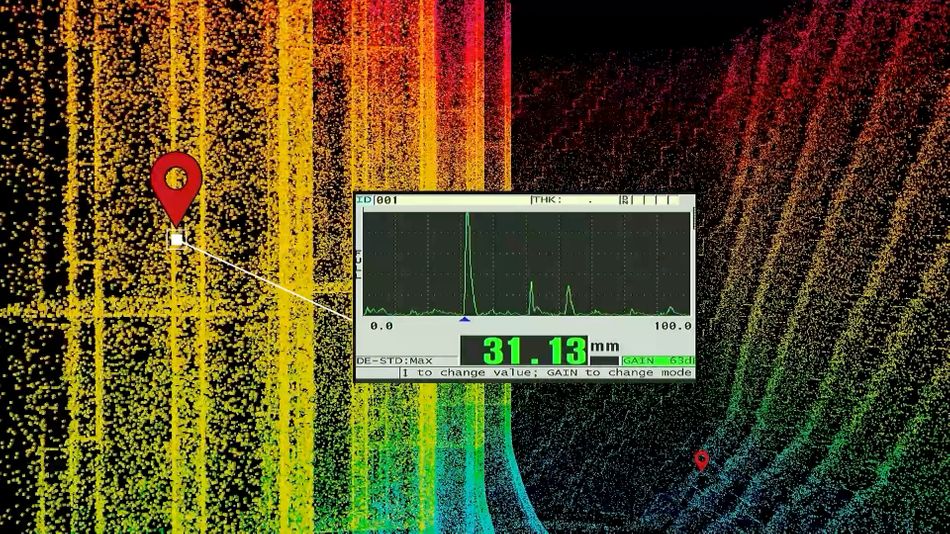

5. Detailed Asset Analysis

The high-resolution point clouds produced by SLAM technology offer detailed insights into the condition of inspected assets. This level of detail supports thorough analysis and detection of even minor defects or anomalies. For precision-critical industries like energy and oil and gas, detailed 3D models facilitate accurate assessment and informed decision-making for maintenance and repairs.

6. Integration with Advanced Technologies

SLAM and 3D mapping are integral to the integration of advanced technologies such as sensor-fusion systems and autonomous navigation. By combining data from multiple sensors, including LiDAR, cameras, and IMUs (Inertial Measurement Units), SLAM enhances the robot’s operational capabilities in diverse and challenging environments. This integration improves the reliability and accuracy of inspections, expanding the range of applications and enhancing overall tool performance.

SKYRON 2’s Contribution

SKYRON 2 exemplifies these advancements by incorporating a sophisticated SLAM processing engine and high-resolution 3D mapping features. Its ability to produce detailed, real-time 3D maps ensures high precision in inspections, even in complex and dynamic environments. The integration of sensor-fusion technology further enhances its effectiveness, providing a comprehensive solution for modern industrial inspection challenges.

In summary, SLAM and 3D mapping are pivotal in advancing the inspection industry by offering enhanced precision, efficiency, real-time navigation, and safety. Avestec’s SKYRON 2 leverages these technologies to deliver a powerful and precise inspection tool, addressing the evolving needs of various industries and setting a new standard in industrial asset inspection and management.